7-64

HDW-750/750CE V1

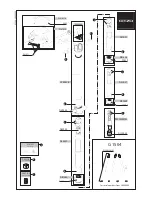

7-17. S1, T1, T3 Tape Guide Replacement

Because the T4 tape guide is fixed, it cannot be replaced. Do not rotate the upper

flange with excessive force.

Replace the following tape guides in units of block.

.

S2 tape guide (Refer to Section 7-32.)

.

S3/S4 tape guide (Refer to Section 7-30.)

.

S5 tape guide (Refer to Section 7-21.)

.

T2 tape guide (Refer to Section 7-33.)

.

T5 Tape guide (Refer to Section 7-22.)

Overview

Replacement

Removing the tape guide

Installing the tape guide

Cleaning of tape guide

Adjustment after Replacement

Tape guide height adjustment

m

.

The tape guides have the various shape, but the same replacement procedure apply

to all of them.

.

When two or more tape guides are going to be replaced, replace tape guides one

guide after another and perform adjustment at every replacement. Adjusting the

two or more tape guides at the same time is extremely difficult.

.

The set screws on top of each tape guide must be tightened with the following

tightening torque.

The standard tightening torque value : 9

x

10

_

2

N

.

m (0.9 kgf

.

cm)

Preparations

1.

Turn off the main power.

2.

Remove the front lid and outside panel assembly. (Refer to Section 1-4.)

3.

Remove the cassette compartment. (Refer to Section 1-9.)

Tools

.

Screwdriver (tool) TG adjustment (45) :

J-6322-420-B

.

Torque screwdriver bit (for M2) :

J-6325-380-A

.

Torque screwdriver (for 3 kg) :

J-6325-400-A

.

Cleaning cloth :

3-184-527-01

.

Cleaning fluid :

9-919-573-01

7-17. S1, T1, T3 Tape Guide Replacement