3 Connection

−

14

−

3.5 Connecting the sensor I/O and user I/O

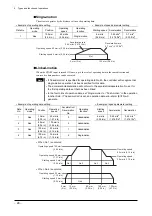

Assembly method

1.

Solder the lead wires to the supplied I/O connectors (the figure shows pin assignments as

viewed from the soldered side).

Applicable lead wire: AWG28 to 26 (0.08 to 0.14 mm

2

)

36

35

2

1

"1" is engraved

20

19

20

19

12

11

2

1

"1" is engraved

•

User I/O

•

Sensor I/O

2.

Assembling the connector.

M2

Tightening torque:

0.3 to 0.35 N·m

(42.6 to 49.7 oz-in)

M2.5

Tightening torque:

0.5 to 0.55 N·m

(71.0 to 78.1 oz-in)

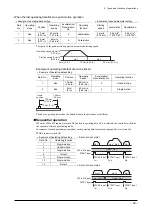

Pin assignments of sensor I/O connector

Pin No.

Signal name

Description

1, 11, 19

IN-COM2

Power supply input for sensor

13

+LS

+LS limit sensor input

14

–LS

–LS limit sensor input

15

HOMELS

HOME sensor input

Note

•

If a photomicrosensor is used and the sensor wiring length is longer than 2 m, provide

an electrolytic capacitor (10 µF, 50 V) at a position within 2 m of the sensor. Refer to the

connection examples shown on pp.17 to 20.

•

When sensors are used, always set the I/O parameter “LS detection enable/disable” to

“Enable.” If it is set to “Disable,” a stop action will not be activated even when a sensor

is detected.

•

IN-COM2 is insulated from IN-COM1 in the user I/O connector. When using sensors, be

sure to connect the power supply.

Содержание EZ limo ESMC-A2

Страница 92: ......