46

EN

M1.1.TZHD30S-50S.NLFREN - 15032019

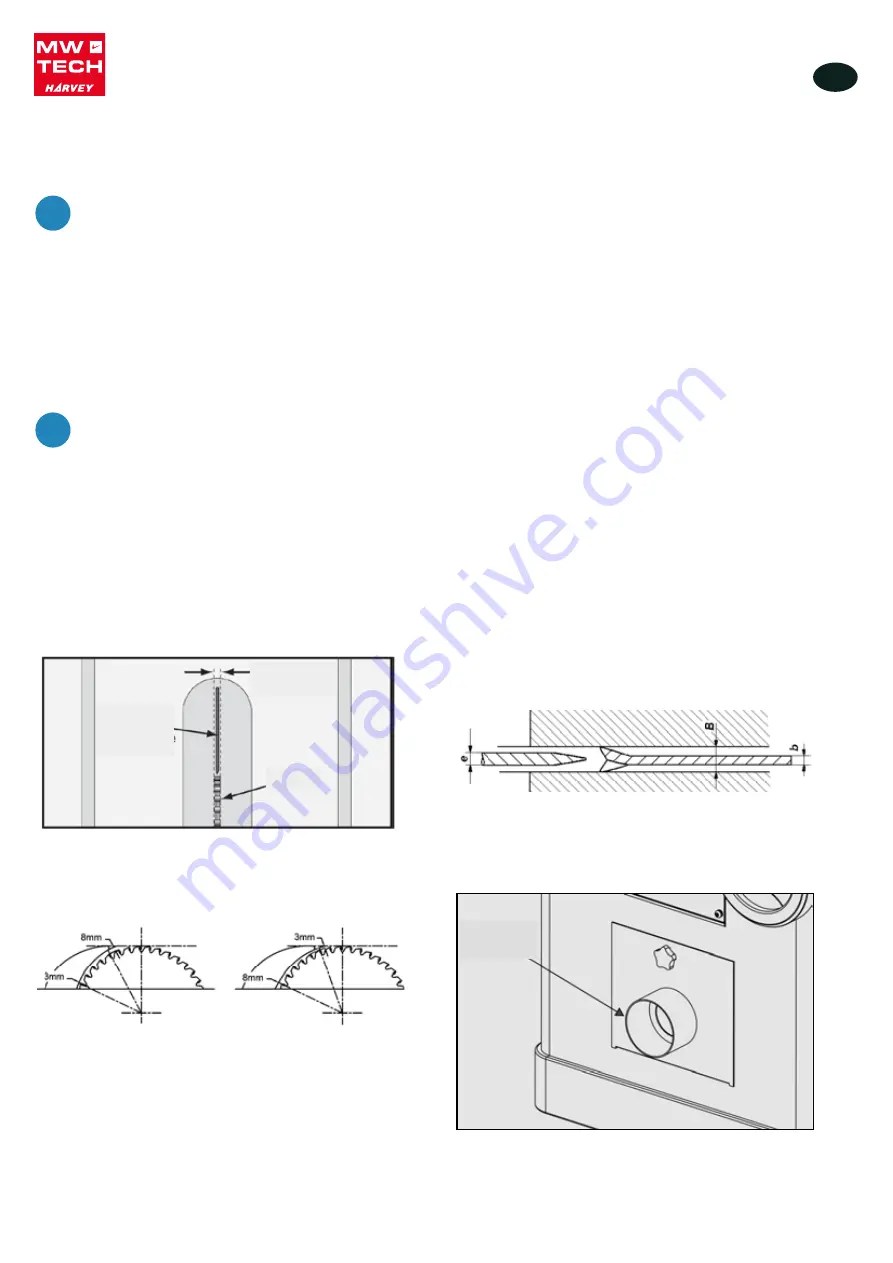

D. Place a straightedge against the blade and the

spreader. When properly aligned, the

spreader/riving knife will be in the "alignment

zone," shown in

Fig.16

, and will be parallel with the

blade.

Fig.16 alignment zone

After changing a saw blade, always check that the

Riving knife or Blade Guard is correctly set!

A. Riving knives shall be manufactured from steel

with an ultimate tensile strength of 580 N mm-2 or

of a comparable material, have flat sides (within

0,1 mm per 100 mm) and shall have a thickness

less than the width of cut (kerf) and at least 0,2mm

greater than the saw blade plate. As

Fig.17

Fig.17

Key:

e riving knife thickness

b saw blade blade

B kerf(width of saw blade cut)

B. The distance of the riving knife from the gear rim

must be between 3mm and 8mm. measured

radially through the centre of the saw spindle. As

Fig.18

Fig.18

C. The highest point of the riving knife must be set

beneath the topmost teeth.

5.4.9 Extraction system

Dust collector device should be prepared by

customer.

The dust extraction equipment is to be

switched on before commencing machining.

The outlet diameter is 100mm.

Fig.19

Air current speed is 20m/s for vacuum suction dust

emission index, when air current speed of dust

collector device (in accordance with EN

12779:2004) is not lower than 20m/s, ensure

machine can be normal exhausted.

1. Required air flow: 800 m3/h;

2. Ensure pressure drop of each dust collector

outlet carrying air current speed: 1100Pa

3. Dry chips: 20m/s.

4. Wet chips: 28m/s. (water content is equal

to18%)

Fig.19

Figure 17

D. Place a straightedge against the blade and the

spreader. When properly aligned, the

spreader/riving knife will be in the "alignment

zone," shown in

Fig.16

, and will be parallel with the

blade.

Fig.16 alignment zone

After changing a saw blade, always check that the

Riving knife or Blade Guard is correctly set!

A. Riving knives shall be manufactured from steel

with an ultimate tensile strength of 580 N mm-2 or

of a comparable material, have flat sides (within

0,1 mm per 100 mm) and shall have a thickness

less than the width of cut (kerf) and at least 0,2mm

greater than the saw blade plate. As

Fig.17

Fig.17

Key:

e riving knife thickness

b saw blade blade

B kerf(width of saw blade cut)

B. The distance of the riving knife from the gear rim

must be between 3mm and 8mm. measured

radially through the centre of the saw spindle. As

Fig.18

Fig.18

C. The highest point of the riving knife must be set

beneath the topmost teeth.

5.4.9 Extraction system

Dust collector device should be prepared by

customer.

The dust extraction equipment is to be

switched on before commencing machining.

The outlet diameter is 100mm.

Fig.19

Air current speed is 20m/s for vacuum suction dust

emission index, when air current speed of dust

collector device (in accordance with EN

12779:2004) is not lower than 20m/s, ensure

machine can be normal exhausted.

1. Required air flow: 800 m3/h;

2. Ensure pressure drop of each dust collector

outlet carrying air current speed: 1100Pa

3. Dry chips: 20m/s.

4. Wet chips: 28m/s. (water content is equal

to18%)

Fig.19

Figure 18

4. Place a straightedge against the blade and the spreader. When properly aligned, the spreader/riving knife will be in the

alignment zone, shown in figure 16, and will be parallel with the blade.

NOTICE

After changing a saw blade, always check that the riving knife or blade guard is correctly set!

1. Riving knives shall be manufactured from steel with an ultimate tensile strength of 580 N/mm² or of a comparable material,

have flat sides (within 0.1 mm per 100 mm) and shall have a thickness less than the width of cut (kerf) and at least 0.2 mm

greater than the saw blade plate (figure 17).

2. The distance of the riving knife from the gear rim must be between 3 mm and 8 mm measured radially through the centre of

the saw spindle (figure 18).

3. The highest point of the riving knife must be set beneath the topmost teeth.

Extraction system

NOTICE

Dust collector device should be prepared by customer�

The dust extraction equipment is to be switched on before commencing machining�

The outlet diameter is 100 mm (figure 19).

Air current speed is 20 m/s for vacuum suction dust emission index. When air current speed of dust collector device (in

accordance with EN 12779:2004) is not lower than 20 m/s, ensure machine can be normal exhausted.

1.

Required air flow: 800 m³/h.

2. Ensure pressure drop of each dust collector outlet carrying air current speed: 1100 Pa

3. Dry chips: 20 m/s

4. Wet chips: 28 m/s (water content is equal to 18%)

!

!

D. Place a straightedge against the blade and the

spreader. When properly aligned, the

spreader/riving knife will be in the "alignment

zone," shown in

Fig.16

, and will be parallel with the

blade.

Fig.16 alignment zone

After changing a saw blade, always check that the

Riving knife or Blade Guard is correctly set!

A. Riving knives shall be manufactured from steel

with an ultimate tensile strength of 580 N mm-2 or

of a comparable material, have flat sides (within

0,1 mm per 100 mm) and shall have a thickness

less than the width of cut (kerf) and at least 0,2mm

greater than the saw blade plate. As

Fig.17

Fig.17

Key:

e riving knife thickness

b saw blade blade

B kerf(width of saw blade cut)

B. The distance of the riving knife from the gear rim

must be between 3mm and 8mm. measured

radially through the centre of the saw spindle. As

Fig.18

Fig.18

C. The highest point of the riving knife must be set

beneath the topmost teeth.

5.4.9 Extraction system

Dust collector device should be prepared by

customer.

The dust extraction equipment is to be

switched on before commencing machining.

The outlet diameter is 100mm.

Fig.19

Air current speed is 20m/s for vacuum suction dust

emission index, when air current speed of dust

collector device (in accordance with EN

12779:2004) is not lower than 20m/s, ensure

machine can be normal exhausted.

1. Required air flow: 800 m3/h;

2. Ensure pressure drop of each dust collector

outlet carrying air current speed: 1100Pa

3. Dry chips: 20m/s.

4. Wet chips: 28m/s. (water content is equal

to18%)

Fig.19

Figure 16 Alignment zone

Blade

Spreader or

riving knife

Alignment

zone

D. Place a straightedge against the blade and the

spreader. When properly aligned, the

spreader/riving knife will be in the "alignment

zone," shown in

Fig.16

, and will be parallel with the

blade.

Fig.16 alignment zone

After changing a saw blade, always check that the

Riving knife or Blade Guard is correctly set!

A. Riving knives shall be manufactured from steel

with an ultimate tensile strength of 580 N mm-2 or

of a comparable material, have flat sides (within

0,1 mm per 100 mm) and shall have a thickness

less than the width of cut (kerf) and at least 0,2mm

greater than the saw blade plate. As

Fig.17

Fig.17

Key:

e riving knife thickness

b saw blade blade

B kerf(width of saw blade cut)

B. The distance of the riving knife from the gear rim

must be between 3mm and 8mm. measured

radially through the centre of the saw spindle. As

Fig.18

Fig.18

C. The highest point of the riving knife must be set

beneath the topmost teeth.

5.4.9 Extraction system

Dust collector device should be prepared by

customer.

The dust extraction equipment is to be

switched on before commencing machining.

The outlet diameter is 100mm.

Fig.19

Air current speed is 20m/s for vacuum suction dust

emission index, when air current speed of dust

collector device (in accordance with EN

12779:2004) is not lower than 20m/s, ensure

machine can be normal exhausted.

1. Required air flow: 800 m3/h;

2. Ensure pressure drop of each dust collector

outlet carrying air current speed: 1100Pa

3. Dry chips: 20m/s.

4. Wet chips: 28m/s. (water content is equal

to18%)

Fig.19

Figure 19

Dust outlet

(100 mm)

copyrighted

document

- all

rights

reserved

by

FBC