April 17, 2000

Man ual Versio n 1.0

1.1

Section 1

Introduction

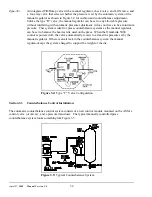

The 5000-10 Auto-Setup Module (ASM) allows the OmniLink 5000 Press and Automation control to

set up press shut height, counterbalance air pressure, cushion air pressures, and hydraulic overload

pressure settings automatically when jobs are recalled from memory. It consists of a base 5000-10

microprocessor board that installs in the OmniLink extended card rack, and additional modules that may

be mounted on the base board to provide pressure or shut height adjustment functions. When one slide

adjust is provided , up to four air systems and a hydraulic overload can be adjusted. For double action or

banjo presses with two slide adjust systems, up to two air systems and a hydraulic overload can be

adjusted.

Section 1.1

Counterbalance Control

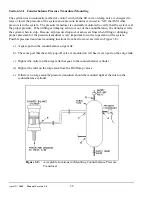

The proper setup of the air counterbalance system in a press is often thought of as a relatively

unimportant detail. In fact, the counterbalance performs a very critical function. By countering the

weight of the slide and its associated tooling a properly adjusted counterbalance:

Takes up bearing clearances before the die closes at the bottom of the stroke, reducing bearing load

and impact.

Helps reduce gear tooth impact in geared machines by maintaining drive edge gear tooth contact in

the press downstroke.

Decreases the downstroke stopping time of the press since less load is seen by the brake in the

downstroke.

Enhances safety by reducing the possibility that the slide will free fall, if the brake is released and

the clutch is not engaged.

Causes less total energy to be used by the press.

Increases drive motor life by reducing peak motor currents.

None of the foregoing advantages will be realized if the counterbalance pressure is set too low. But a

counterbalance pressure that is set too high is also detrimental to the press, causing excessive clutch

wear and loss of flywheel energy in the downstroke before material is contacted by the dies.

By setting the pressure automatically when a job is recalled, the OmniLink 5000 assures that the

pressure is correct for the tooling used. This not only reduces machine maintenance, but increases safety

and speeds up job setup tremendously. In addition, the Auto-Setup module sets the correct pressure for

each die, rather than an approximate pressure for a range of die weights from tables provided with

manually adjustable counterbalance systems.

Section 1.2

Cushion Control

Quick die change is becoming increasingly important to maintaining a competitive edge. By controlling

up to four cushions automatically, the OmniLink 5000 can shorten die change and assure a correct setup

in the least amount of time.

Содержание OmniLink 5000

Страница 5: ...April 17 2000 Manual Versio n 1 0 iv...

Страница 38: ...April 17 2000 Manual Versio n 1 0 4 14...

Страница 63: ...April 17 2000 Manual Versio n 1 0 B 2 Figure B 2 Typical Cushion Wiring Diagram...

Страница 64: ...April 17 2000 Manual Versio n 1 0 B 3 Figure B 3 Conceptual Dual Resolver Mounting...

Страница 65: ...April 17 2000 Manual Versio n 1 0 B 4 Figure B 4 Typical AMCI Dual Resolver Wiring Diagram...

Страница 66: ...April 17 2000 Manual Versio n 1 0 B 5 Figure B 5 Typical GEMCO Dual Resolver Wiring Diagram...

Страница 67: ...April 17 2000 Manual Versio n 1 0 B 6 Figure B 6 Conceptual Linear Transducer Mounting...

Страница 68: ...April 17 2000 Manual Versio n 1 0 B 7 Figure B 7 Typical GEMCO Linear Transducer Wiring...

Страница 69: ...April 17 2000 Manual Versio n 1 0 B 8 Figure B 8 Typical MTS Temposonics II Linear Transducer Wiring...

Страница 71: ...April 17 2000 Manual Versio n 1 0 B 10...

Страница 73: ...April 17 2000 Manual Versio n 1 0 C 2...