April 17, 2000

Man ual Versio n 1.0

4.8

parameter is currently selected. Softkey 1 (the uppermost vertical softkey) will change its description

based on the parameter and, when pressed, allows the currently selected parameter to be changed. The

up and down arrow keys move the editing cursor from one parameter to another.

See Appendix A for

examples of setting up each kind of system.

The features of this screen are:

Help

The “Help” box at the bottom of the screen changes depending on the parameter

that the editing cursor is currently on. It gives a short version of how the

parameter is used.

Slide Slot

Corresponds to the physical slot number (SS1 in the example of Figure 4.3)

selected for configuration on the auto-setup card. The “NEXT SLIDE SLOT”

softkey will cycle between SS1 and SS2.

Hardware Detected

This will be “Linear Transducer” for 5000-10B option boards or “Rotary

Transducer for 5000-10C option boards. If there is no option board installed in

that slot this should read “None Detected”.

Shutheight

The current slide position reported by the transducer.

NOTE!

This number will be

incorrect until Cal. Position and Orientation are entered during configuration.

This is reported as a convenience in this screen cannot be changed by the user.

Name

Use the “CHANGE NAME” soft key repetitively to cycle through the available

names for this system (Slide Adjust #1, Slide Adjust #2, Not Configured). Stop

when the desired name appears. This name will appear on the Auto-Sets screen.

Mode

Use the “CHANGE MODE” soft key to cycle the status from

ON

to

MAN

to

OFF

and back to

ON

.

ON

means the OmniLink 5000 automatically adjusts to the

new shut height associated with a job when that job is recalled from memory, but

only

if the Slide Adjust OFF/ON selector switch is turned to the ON position.

MAN

means the OmniLink 5000 can control the shut height but the shut height

can only be changed from the “Slide Adjust” screen. A

RECALLED

job will

NOT

change the shut height, although an operator can cause the system to

automatically adjust to a new shut height by turning the Slide Adjust OFF/ON

switch to the ON position, entering the desired shut height value in the “Slide

Setpoint” row, and pressing the “AUTO ADJUST” softkey.

OFF

means the 5000

will not automatically adjust the shut height, and will ignore any errors from the

system. Operators can always manually jog the slide into position through the use

of the “JOG UP” and “JOG DOWN” softkeys. These keys appear when the Slide

Adjust OFF/ON switch is in the ON position regardless of whether

ON, MAN,

or

OFF

is configured. This value should typically be set to ON.

Shut Height Units

All shutheight parameters and the shut height actual position can be displayed and

entered in inches or millimeters. Use the “CHANGE UNIT” softkey to toggle

this setting between inches and millimeters. Note that values already entered will

be converted to the new unit.

Содержание OmniLink 5000

Страница 5: ...April 17 2000 Manual Versio n 1 0 iv...

Страница 38: ...April 17 2000 Manual Versio n 1 0 4 14...

Страница 63: ...April 17 2000 Manual Versio n 1 0 B 2 Figure B 2 Typical Cushion Wiring Diagram...

Страница 64: ...April 17 2000 Manual Versio n 1 0 B 3 Figure B 3 Conceptual Dual Resolver Mounting...

Страница 65: ...April 17 2000 Manual Versio n 1 0 B 4 Figure B 4 Typical AMCI Dual Resolver Wiring Diagram...

Страница 66: ...April 17 2000 Manual Versio n 1 0 B 5 Figure B 5 Typical GEMCO Dual Resolver Wiring Diagram...

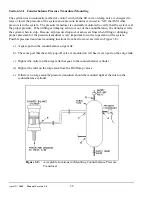

Страница 67: ...April 17 2000 Manual Versio n 1 0 B 6 Figure B 6 Conceptual Linear Transducer Mounting...

Страница 68: ...April 17 2000 Manual Versio n 1 0 B 7 Figure B 7 Typical GEMCO Linear Transducer Wiring...

Страница 69: ...April 17 2000 Manual Versio n 1 0 B 8 Figure B 8 Typical MTS Temposonics II Linear Transducer Wiring...

Страница 71: ...April 17 2000 Manual Versio n 1 0 B 10...

Страница 73: ...April 17 2000 Manual Versio n 1 0 C 2...