2-83

Service Manual

4447-20x

Go Back

Previous

Next

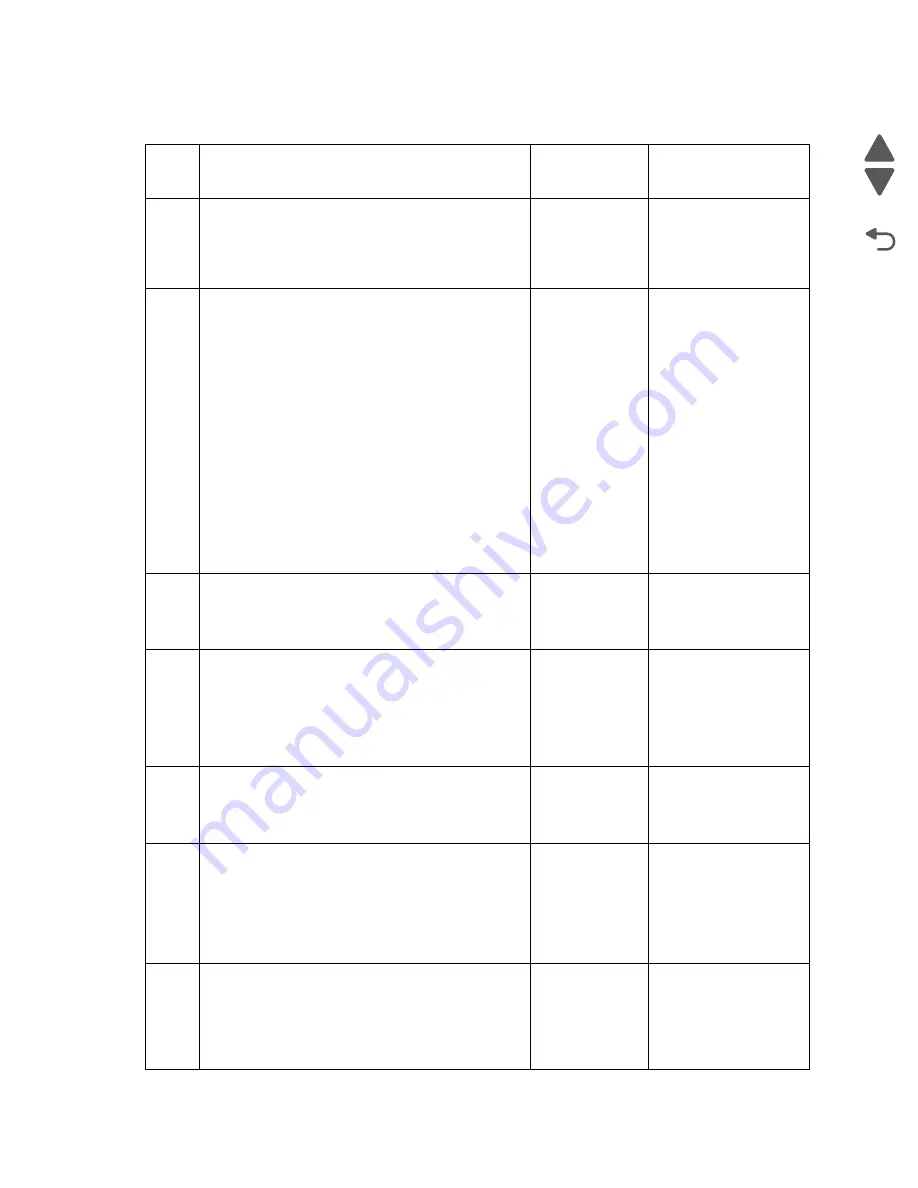

Printer paper jam (fails to reach the EOF sensor) service check

Step

Check

Yes

No

1

Check the leading edge of the paper for any

damage. Check for any obstruction in the paper

path.

Is the leading edge of the paper free from any

damage?

Go to step 2.

Clear the paper path

for any obstruction.

2

Remove the input tray, and check the following

conditions for the paper:

• If it is within the stack limit.

• If it is within the specifications.

• If it has any defects like curls and folds.

• If it is properly placed in the input tray.

Is the paper within specifications and free from

any defects?

Go to step 3.

Do any of the

following:

• Refer to the paper

specifications. See

“Media input type

specifications”

on page 1-20

“Media input

sizes

specifications”

on page 1-20

• If defects are

found, then replace

the paper.

• If the paper is

beyond the stack

limit, then lessen

the paper in the

input tray.

3

Check the pick tires for wear, contamination, and

damage.

Are the pick tires contaminated, damaged, or

worn?

Go to step 10.

Go to step 4.

4

Remove the duplex unit. See

. Check the staging sensor

flag for any mechanical damage. Check the J34

cable and connector on the system board for proper

connection. Reseat the J34 cable.

Is the staging sensor flag free from any

damage?

Go to step 5.

Go to step 15.

5

Check the J26 connector for proper connection.

Reseat the J26 cable. Check the EOF sensor for

any mechanical damage.

Is the EOF sensor free from any damage?

Go to step 6.

Go to step 15.

6

Check the following:

• If there are any damage on the duplex rollers.

• If there are any damage on the duplex flaps.

• If the duplex unit is properly inserted.

Is the duplex unit free from any damage?

Go to step 7.

Go to step 12.

7

Check the feed assist rollers for wear and

contamination. Check the paper for skid marks,

which could be possible roller slips during picking.

Are the feed assist rollers worn or damaged?

Do any of the

following:

• Clean the

rollers.

• Go to step

15.

Go to step 8.

Содержание Pro5500 Series

Страница 11: ...Safety information xi 4447 20x Go Back Previous Next 012 3456789...

Страница 191: ...Repair information 4 22 4447 20x Go Back Previous Next Disassembly Flow chart This is the photo of the ADF input tray...

Страница 254: ...4 85 Service Manual 4447 20x Go Back Previous Next Disassembly Flow chart...

Страница 260: ...5 6 Service Manual 4447 20x Go Back Previous Next Wireless card Card reader JP3...

Страница 261: ...Connector locations 5 7 4447 20x Go Back Previous Next Carrier card J1 J2 J3...

Страница 262: ...5 8 Service Manual 4447 20x Go Back Previous Next...

Страница 266: ...7 2 Service Manual 4447 20x Go Back Previous Next Assembly 1 Covers 5 6 8 9 10 11 12 13 16 17 1 14 15 7 2 3 4...

Страница 268: ...7 4 Service Manual 4447 20x Go Back Previous Next Assembly 2 Engine 1 2 3 5 4...

Страница 270: ...7 6 Service Manual 4447 20x Go Back Previous Next Assembly 3 Fluid system assembly 1 3 2 5 4...

Страница 274: ...7 10 Service Manual 4447 20x Go Back Previous Next...

Страница 277: ...I 3 Service Manual 4447 20x Go Back Previous Next...