Snap Action Cable Pull Safety Limit Switch

ISSUE 3

PK 81592

2 For application help: call 1-800-537-6945

Honeywell

•

MICRO SWITCH Sensing and Control

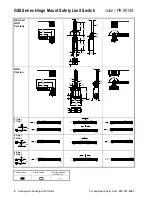

Figure 3: Typical Single Head Switch Installation

1

2

3

4

Key

1. 12 in (30 cm) maximum

2. 8 ft (2,4 m)

3. 200 ft (60 m) maximum

4. Actuating cable

Figure 4: Typical Duplex Head Switch Installation

Key

1. 12 in (30 cm) maximum

2. 8 ft (2,4 m)

3. 200 ft (60 m) maximum

4. Actuating cable

SWITCH MOUNTING, WIRING AND SEALING

In order to comply with EN418, install a cable pull

switch at each end of the cable.

Step 1 - Ensure you have the following:

•

Switch.

•

(2) #10-32 UNF screws.

•

#14-#16 AWG stranded or #16-#18 AWG solid

wire.

Step 2 - Mount switch:

SWITCH DAMAGE

Do NOT mount switch upside down or at low point

of conduit runs. Condensation problems may

develop.

Failure to comply with these instructions may

result in product damage.

•

Single head: Mount using two #10-32 UNF

screws from either front or back of switch. Ensure

a minimum of four threads of engagement.

Torque to 43-52 in-lb (4,-5,9 N-m).

•

Duplex head: Mount using two #10-32 UNF

screws through mounting feet on left and right of

switch enclosure. Ensure a minimum of four

threads of engagement. Torque to 43-52 in-lb

(4,9-5,9 N-m).

S

tep 3 - Wire switch:

•

Connect stranded or solid wire to switch’s

pressure type connector terminals. (Refer to

circuit diagram on switch housing. Diagram

depicts switch contacts when cable is at proper

tension.) Torque terminal screws and ground

screw to 7-9 in-lb (0,8-1 N-m).

Step 4 - Seal conduit connection:

•

Seal with Teflon tape or pipe dope. If connector

is used to secure cable to enclosure, torque

connector to 16-19 in-lb (1,8-2,2 N-m).

IMPROPER SYSTEM PERFORMANCE

•

The Maintained Cable Pull Safety Limit Switch

provides only the front end switching/sensing

function. The external machine interfaces, and

the safety monitoring of those interfaces, is the

responsibility of the machine safety control

system.

•

Consult all local, state, and national laws, rules,

codes, and regulations relating to the use of

safety switches, machine interfaces and safety

monitoring that affect safety.

•

The user is SOLELY RESPONSIBLE for

determining the appropriate level of risk

warranting this type of machine safety control

system.

•

Maintained Cable Pull Safety Limit Switches must

be installed in a fashion that complies with all

codes and standards that are applicable to the

particular application of the device.

Failure to comply with these instructions

could result in death or serious injury.

Содержание SYA14 Series

Страница 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Страница 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 84: ......

Страница 158: ......

Страница 160: ......

Страница 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Страница 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Страница 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Страница 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Страница 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Страница 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Страница 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Страница 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Страница 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Страница 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Страница 263: ...PK 107007 1 EN FR26 GLO 298 Printed in France Safety Mat Installation Manual FF SM Series Safety Mat PK 107007 Issue 1 ...

Страница 264: ...ii Honeywell PK 107007 01 EN FR26 GLO 0298 Printed in France For application help see Warranty Information ...

Страница 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Страница 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Страница 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Страница 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Страница 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Страница 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Страница 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Страница 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Страница 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...