EN 60947-5-1-3

pending

Issue 2

PK 80086

Installation Instructions for the Global Safety Limit Switch (GSS Series)

Instrucciones de instalación para los interruptores de fin de carrera (serie GSS)

Einbauanweisungen für den Sicherheits-Positionsschalter (Serie GSS)

Instructions d’installation du fin de course standard de sécurité (série GSS)

Istruzioni per l'installazione del finecorsa di sicurezza (Serie GSS)

Instruções de Instalação para o Switch de Fim de Curso de Segurança Global

(Série GSS)

Sensing and Control

WARNING

IMPROPER INSTALLATION

•

Consult with local safety agencies and their requirements when

designing a machine-control link, interface, and all control

elements that affect safety.

•

Strictly adhere to all installation instructions.

Failure to comply with these instructions could result in

death or serious injury.

MOUNT, WIRE AND SEAL SWITCH

WARNING

IMPROPER OPERATION

•

Ensure switch actuator achieves sufficient travel for positive

opening of normally closed (NC) contacts to occur.

Failure to comply with these instructions could result in

death or serious injury.

1. Refer

to:

•

Page 3 for adjustments.

•

Page 4 for EN 50041 wiring configurations for each switch

code. (Ag=silver contacts, Au=gold-plated contacts)

•

Pages 5 and 6 for specific travel distances for each switch

code, and specifications.

•

Page 7 proper application of limit switches, and switch

mounting dimensions.

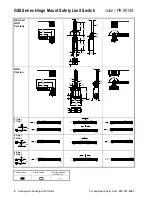

2. Perform adjustments (if desired). Use the TORX

tamper-

resistant bit (included):

•

Head orientation (Figure 1).

•

Actuation direction (Figure 2).

•

Side rotary switches with 90

°

positive drive levers (catalog

listings ending in A1A, A1B, A5A, A5B) (Figure 3):

−

Ensure flats of switch shaft engage groove in actuator

lever.

−

Tighten locking screw (A) until tab (B) no longer moves.

3. Mount switch using four M5 or #10 screws. Torque screws to

4,9-5,9 N m (43-52 in lb).

4. Remove tamper-proof screws on cover plate.

5. Connect stranded wire (0,75 mm

2

-2,5 mm

2

, 18-14 AWG) or

solid wire (0,75 mm

2

to 1,5 mm

2

, 18-16 AWG) to connector

terminals (use 90

°

C wire when ambient temperature is over

75

°

C). Torque switch terminal screws to 0,8-1,0 N m

(7-9 in lb).

6. Seal conduit opening according to instructions in PK 80112.

7. Reassemble

cover

plate

ADVERTENCIA

INSTALACIÓN INCORRECTA

•

Consulte las normas de seguridad y sus requisitos al realizar el

diseño del enlace de control de una máquina, la interfaz, y los

elementos de control que afecten a la seguridad.

•

Siga estrictamente todas las instrucciones para la instalación.

El incumplimiento de estas recomendaciones puede

ocasionar lesiones graves o peligro de muerte.

MONTAJE, CABLEADO Y SELLADO DEL INTERRUPTOR

ADVERTENCIA

FUNCIONAMIENTO INCORRECTO

•

Asegúrese que el actuador del interruptor tenga la suficiente

carrera para que se produzca la apertura positiva de los

contactos normalmente cerrados (NC).

El incumplimiento de estas recomendaciones puede

ocasionar lesiones graves o peligro de muerte.

1. Consulte:

•

la página 3 para los ajustes

•

la página 4 para las configuraciones de cableado EN 50041

para cada código de interruptor. (Ag=contactos de plata,

Au=contactos de oro)

•

las páginas 5 y 6 para las distancias de carrera específicas

de cada código de interruptor y las especificaciones.

•

la página 7 para la correcta aplicación de los interruptores

final de carrera y las dimensiones de montaje del

interruptor.

2. Realice los ajustes (si fuera necesario). Utilice el tornillo

TORX

resistente a alteraciones (incluido):

•

Orientación del cabezal (véase la figura 1).

•

Dirección del accionamiento (véase la figura 2).

•

Interruptores de rotación lateral con palancas de impulsión

positiva de 90º (las referencias del catálogo que terminen

en A1A, A1B, A5A, A5B) (véase la figura 3):

−

Asegúrese de que las caras del eje del interruptor

enganchen la ranura de la palanca del actuador.

−

Ajuste el tornillo de apriete (A) hasta que la lengüeta (B)

deje de moverse.

3. Para montar el interruptor, utilice cuatro tornillos M5 o del

número 10. Ajuste los tornillos hasta

4,9-5,9 N m (43-52 pulg.

lb).

4. Retire los tornillos garantizados contra toda alteración de la

tapa.

5. Conecte cable trenzado (0,75 mm

2

-2,5 mm

2

, 18-14 AWG) o

cable sólido (0,75 mm

2

a 1,5 mm

2

, 18-16 AWG) a los

terminales del conector (utilice cable de 90

°

C cuando la

temperatura ambiente supere los 75

°

C). Ajuste los tornillos

de los terminales hasta 0,8-1,0 N m (7-9 pulg. lb).

6. Selle el conducto de entrada según las instrucciones en PK 80112

7. Vuelva a colocar en su sitio la tapa.

Содержание SYA14 Series

Страница 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Страница 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Страница 84: ......

Страница 158: ......

Страница 160: ......

Страница 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Страница 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Страница 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Страница 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Страница 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Страница 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Страница 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Страница 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Страница 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Страница 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Страница 263: ...PK 107007 1 EN FR26 GLO 298 Printed in France Safety Mat Installation Manual FF SM Series Safety Mat PK 107007 Issue 1 ...

Страница 264: ...ii Honeywell PK 107007 01 EN FR26 GLO 0298 Printed in France For application help see Warranty Information ...

Страница 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Страница 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Страница 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Страница 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Страница 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Страница 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Страница 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Страница 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Страница 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...