Model G0841 (Mfd. Since 06/18)

-71-

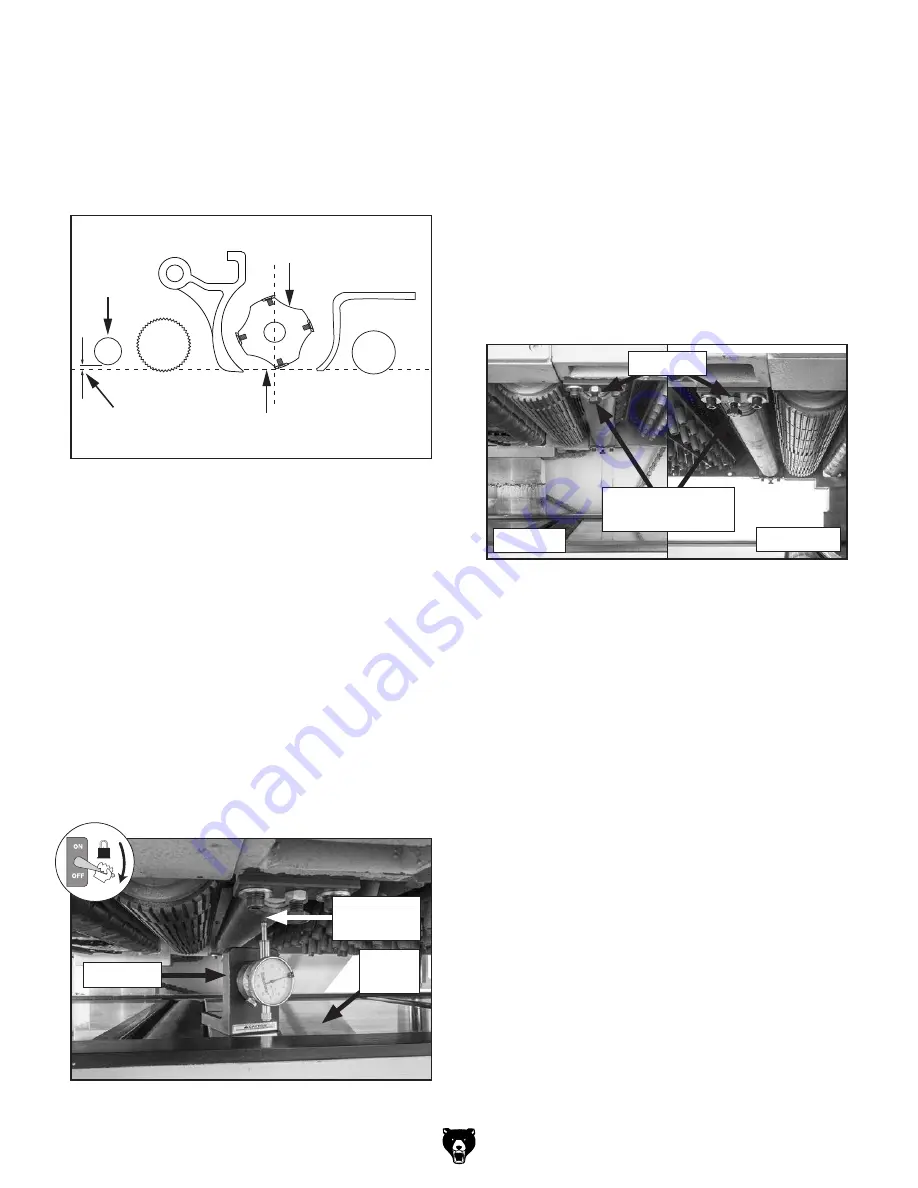

To adjust idler roller height:

1. Set upper cutterhead at BDC. (Refer to

Setting Upper Cutterhead at BDC on

Page 67).

2. DISCONNECT AND LOCK-OUT MACHINE

AT POWER SOURCE!

3. Place Rotacator or dial indicator on planer

table underneath left-side of idler roller (see

Figure 111).

Item(s) Needed:

Qty

Rotacator or Dial Indicator w/Base .................... 1

Wrench Open-Ends or Socket 13mm ................ 2

4. Slide Rotacator or dial indicator back and

forth across bottom of idler roller.

— If idler roller height is 0.080–0.120" above

BDC, then no height adjustment is neces-

sary. Skip to

Step 7.

— If idler roller height is not 0.080–0.120"

above BDC, then adjust height of idler

roller. Proceed to

Step 5.

5. Loosen idler roller jam nut and height adjust-

ment bolt (see

Figure 112).

Figure 111. Rotacator placed underneath left-

side of idler roller.

6. Tighten or loosen height adjustment bolt as

needed to set correct idler roller height, and

then tighten jam nut to secure correct height

setting.

7. Repeat Steps 3–6 on right-side of idler roller.

8. If needed, repeat Steps 3–7 until entire idler

roller height is correct.

Figure 112. Location of idler roller height

adjustment hardware.

Adjusting Idler Roller

0.080–0.120"

Upper

Cutterhead

BDC

(Bottom Dead Center)

Idler

Roller

Figure 110. Correct idler roller height.

For best thickness planing results, set the idler

roller 0.080–0.120" above BDC, as shown in

Figure 110. Prior to adjusting idler roller, the

headstock must be square to the table. (Refer to

Squaring Headstock on Page 68.)

adjusting idler roller

Planer

Table

Rotacator

Bottom of

Idler Roller

Rightside

Leftside

Jam Nuts

Height

Adjustment Bolts

Содержание G0841

Страница 84: ......