Model G0841 (Mfd. Since 06/18)

-51-

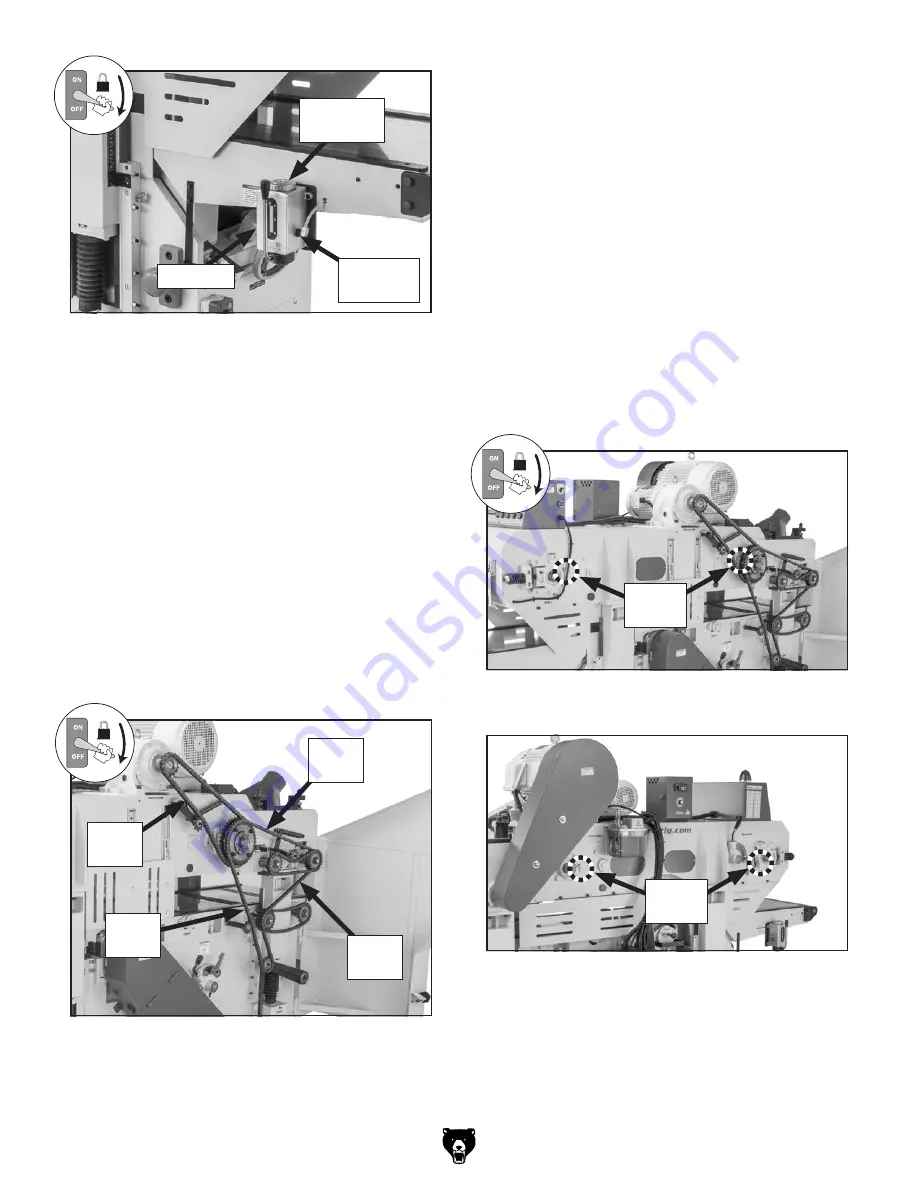

Figure 70. Location of chain drive.

Chain

Drive

Chain

Drive

Chain

Drive

Chain

Drive

Chain Drive

Lube Type ............ T26419 or NLGI#2 Equivalent

Lube Amount .......................................Light Coat

Lube Frequency .......................................... Daily

Item(s) Needed:

Qty

Grease Brush .................................................... 1

Stiff Brush .......................................................... 1

Mineral Spirits .................................... As Needed

Shop Rags ......................................... As Needed

The chain drive (see

Figure 70) supplies power

to the feed track, serrated roller, and pressure

rollers. To ensure smooth power delivery, clean

chain drive daily with mineral spirits, stiff brush,

and shop rags, and allow chain to dry, then lightly

grease the chain drive at several points.

chain drive

Figure 72. Location of feed track roller bearings

grease fittings—leftside.

Grease

Fittings

Feed Track Bearings & Slideways

Lube Type ............. T26419 or NLGI#2 Equivalent

Lube Amount ...........................................1 Pump

Lube Frequency ..................................200 Hours

Item(s) Needed:

Qty

Grease Gun ....................................................... 1

Shop Rags ......................................... As Needed

The feed track bearings and associated slideways

require a small amount of grease every 200 hours

of operation to ensure smooth feed track move-

ment and tensioning. The feed track bearings

and slideways are lubricated by grease fittings

(see

Figures 71–73). Wipe grease fittings clean

and use a grease gun to pump a small amount of

grease into fittings, then wipe away any excess

grease with a rag.

Figure 71. Location of feed track roller bearings

grease fittings—rightside.

Grease

Fittings

feed belt bearings slideways

Figure 69. Location of one-shot oiler.

One-Shot

Oiler

Reservoir

Fill Cap w/

Vent Slot

Содержание G0841

Страница 84: ......