-56-

Model G0841 (Mfd. Since 06/18)

Review the troubleshooting procedures in this section if a problem develops with your machine. If you need

replacement parts or additional help with a procedure, call our Technical Support.

Note: Please gather the

serial number and manufacture date of your machine before calling.

SECTION 7: SERVICE

Troubleshooting

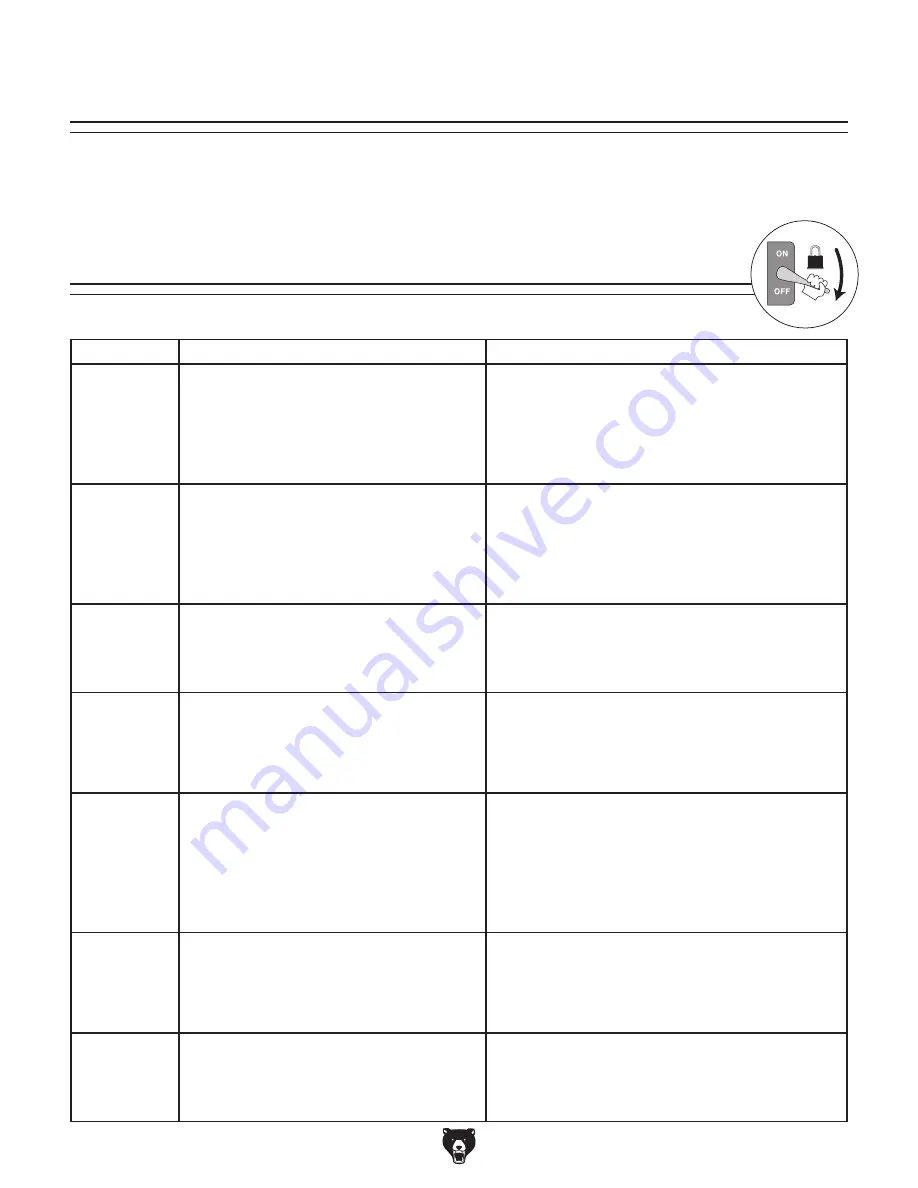

Motor & Electrical

Symptom

Possible Cause

Possible Solution

Control panel

will not startup.

1. E-Stop Button(s) engaged or at fault.

2. Power supply turned OFF at source.

3. Power supply circuit breaker tripped or fuse

blown.

4. Incorrect power supply voltage or circuit size.

1. Rotate E-Stop Button(s) to reset. Replace if

necessary.

2. Turn power supply ON.

3. Reset circuit breaker on machine or at power supply

source; replace fuse.

4. Contact certified electrician for repair.

Elevation

system will not

raise/lower

headstock.

1. Elevation limit switch(es) triggered or at fault.

2. Height adjustment switch(es) at fault.

3. Magnetic contactor(s) at fault.

4. Headstock not square to table.

5. Motor/gearbox at fault.

1. Adjust limit switch(es); test/repair/replace.

2. Test/repair/replace.

3. Test/repair/replace contactors inside electrical panel;

contact certified electrician for repair.

4. Square headstock (

Page 68).

5. Test/repair/replace.

Elevation

system

raises/lowers

headstock in

reverse.

1. Incoming power supply out-of-phase.

1. Switch any two of three incoming power supply wires

at terminal block inside electrical panel (

Page 28).

Elevation

system will not

startup.

1. Wiring open/has high resistance.

2. Component in motor(s) power circuit at fault.

3. Magnetic contactor(s) at fault.

4. Motor(s) at fault.

1. Check/fix broken, disonnected, or corroded wires.

2. Contact certified electrician for repair.

3. Test/repair/replace contactors inside electrical panel;

contact certified electrician for repair.

4. Test/repair/replace.

Upper and/

or lower

cutterhead will

not startup.

1. Safety interlock switch(es) triggered at fault.

2. Wiring open/has high resistance.

3. Cutterhead switch(es) at fault.

4. Component in motor(s) power circuit at fault.

5. Magnetic contactor(s) at fault.

6. Motor(s) at fault.

1. Adjust limit switch(es); test/repair/replace.

2. Check/fix broken, disonnected, or corroded wires.

3. Test/repair/replace.

4. Contact certified electrician for repair.

5. Test/repair/replace contactors inside electrical panel;

contact certified electrician for repair.

6. Test/repair/replace.

Feed system

will not startup.

1. Start delay sequence not completed.

2. Wiring open/has high resistance.

3. Component in motor(s) power circuit at fault.

4. Motor at fault.

1. Upper and lower cutterheads must be ON and reach

full speed before feed system will startup.

2. Check/fix broken, disonnected, or corroded wires.

3. Contact certified electrician for repair.

4. Test/repair/replace.

Power-supply

fuse/breaker

immediately

trips after

startup.

1. Machine has short in power supply circuit.

2. Power supply circuit undersized for machine

or fuse/breaker at fault.

1. Contact certified electrician for repair.

2. Ensure proper power supply; replace fuse/breaker;

contact certified electrician for repair.

Содержание G0841

Страница 84: ......