Model G0841 (Mfd. Since 06/18)

-69-

1. Set upper cutterhead at BDC. (Refer to

Setting Upper Cutterhead at BDC on

Page 67).

2. DISCONNECT AND LOCK-OUT MACHINE

AT POWER SOURCE!

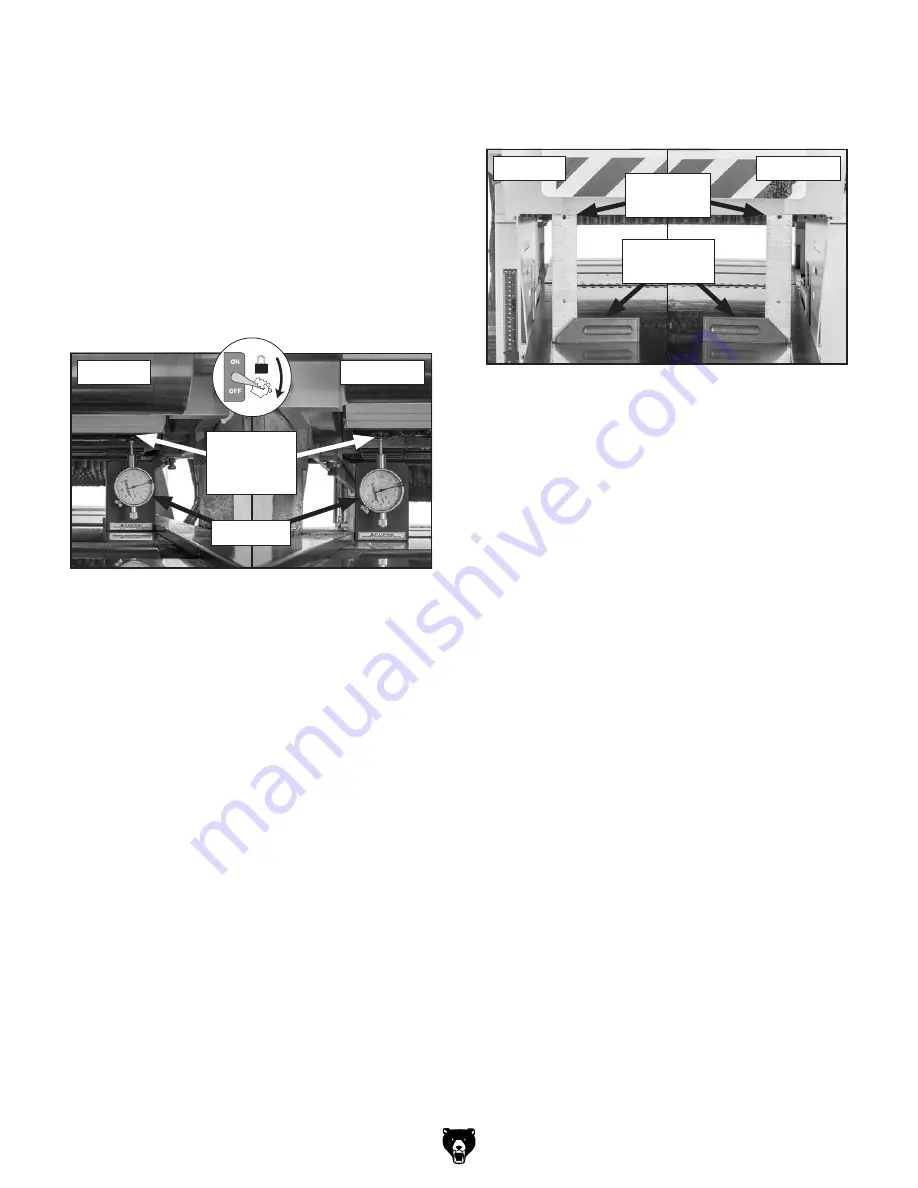

3. Place Rotacator or dial indicator on plan-

er table directly under inserts on leftside

and rightside edge of upper cutterhead (see

Figure 108).

Checking/Squaring Headstock Side-

to-Side

checking squaring headstock side

— If leftside and rightside of headstock are

within 0.050" of one another, then no fur-

ther adjustments are necessary.

— If leftside and rightside of headstock

are not within 0.050" of one another, then

determine which side is higher and pro-

ceed to

Step 7.

7. On side of machine where headstock is

higher, loosen (2) cap screws securing eleva-

tion leadscrew collar (see

Figure 107 on

Page 68).

8. Turn elevation leadscrew collar (see

Figure 107 on Page 68) counterclockwise

until leftside and rightside of headstock are

even, and then tighten (2) cap screws secur-

ing elevation leadscrew collar.

9. Set headstock height. (Refer to Setting

Headstock Height on Page 70.)

— If inserts are at BDC, then proceed to

Step 6.

— If edge inserts are not at BDC, then deter-

mine which side is higher and proceed to

Step 4.

4. On side of machine where headstock is

higher, loosen (2) cap screws securing eleva-

tion leadscrew collar (see

Figure 107 on

Page 68).

5. Turn elevation leadscrew collar (see

Figure 107 on Page 68) counterclockwise

until inserts on leftside and rightside edge

of upper cutterhead are at BDC, and then

tighten (2) cap screws securing elevation

leadscrew collar.

Figure 109. Capenter's square placed under

front edge of headstock.

Figure 108. Rotacator placed under inserts on

edge of upper cutterhead.

Rightside

Leftside

Rotacator

Inserts on

Edge of

Cutterhead

6. Place carpenter's square on rightside and

leftside of infeed table under front edge of

headstock (see

Figure 109).

Rightside

Leftside

Edge of

Headstock

Carpenter's

Square

Содержание G0841

Страница 84: ......