Model G0841 (Mfd. Since 06/18)

-41-

Setting Feed Rate

The Model G0841 feed system includes a feed

track, serrated roller, three pressure rollers, and a

chain drive. The feed system moves workpieces

through the machine while keeping them flat

and providing a consistent rate of movement.

The speed at which the feed system moves the

workpieces through the machine is the feed rate.

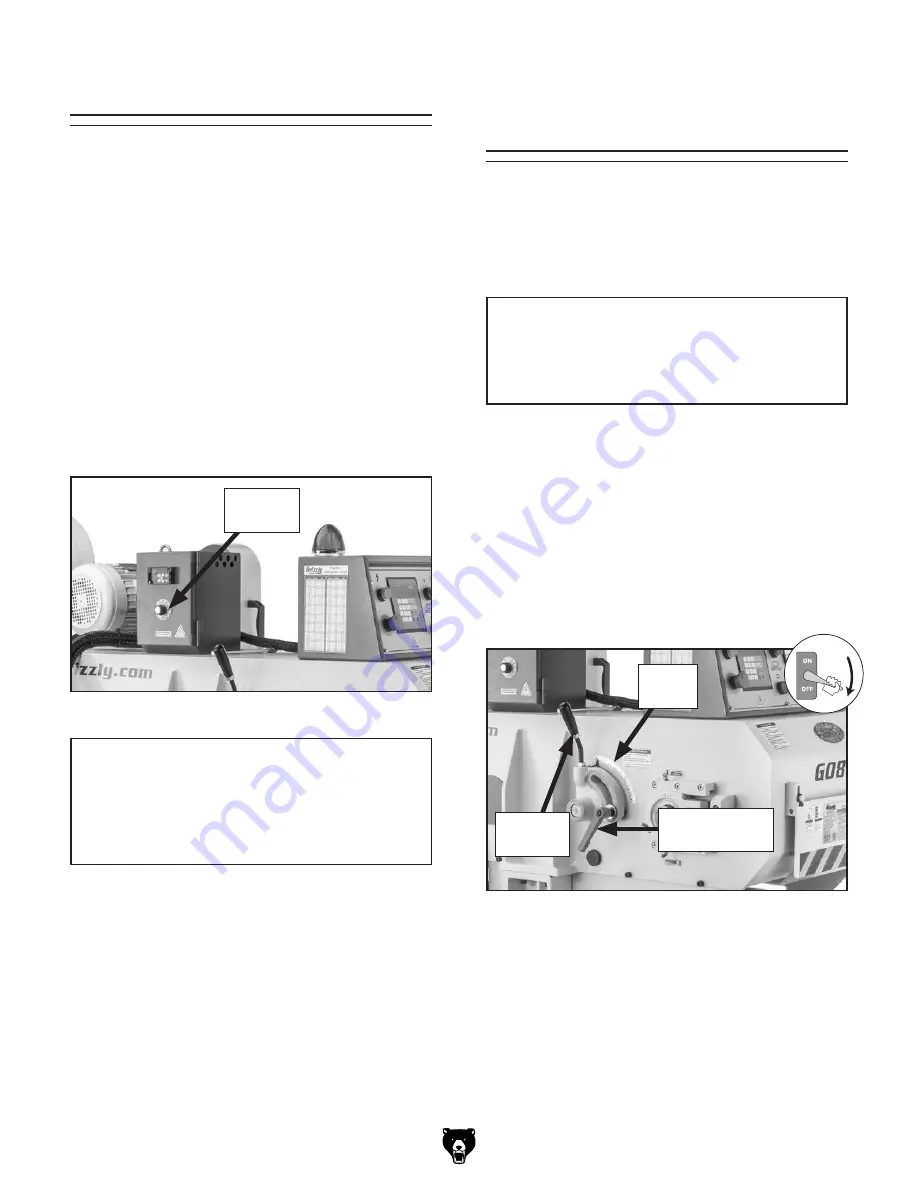

The feed rate dial (see

Figure 47) is a potentiom-

eter that allows you to adjust the feed rate from

26–72 feet per minute (FPM). The correct speed

to use depends on the type of stock you are using

(hardwood vs. softwood) and the stage of finish

with that workpiece. Generally, low feed rates are

used for dimensioning passes, while higher feed

rates are used for finishing passes.

NOTICE

ALWAYS start feed system with feed dial

set to 0% (26 FPM), and DO NOT attempt to

change feed rate during cutting operations

or damage to the machine may result.

Figure 47. Location of feed rate dial.

Feed

Rate Dial

Adjusting Feed Track

Pressure

setting feed rate

adjusting feed belt pressure

If you notice the feed track slipping on workpieces

during planing operations, adjust the downward

pressure of the feed track. For normal operations,

set the feed track at "0". Only adjust the downward

pressure of the feedbelt 0.5mm at a time.

To adjust feed track pressure:

1. DISCONNECT AND LOCK-OUT MACHINE

AT POWER SOURCE!

2. Loosen

pressure

lock

lever

(see

Figure 48) and pull down on pressure lever

(see

Figure 48) until scale pointer indicates

"0.5mm" While holding pressure lever in posi-

tion, tighten pressure lock lever.

Figure 48. Location of feed track pressure

adjustment compontents.

3. Connect machine to power and test feed

track pressure, if feed track continues to slip

on workpieces, repeat

Step 2 until proper

feed track pressure is achieved.

Scale

Pointer

Pressure

Lever

Pressure Lock

Lever

NOTICE

Heavy use of downward feed belt pres-

sure will accelerate wear of feed belt

components.

Содержание G0841

Страница 84: ......