Model G0841 (Mfd. Since 06/18)

-23-

Lifting & Placing

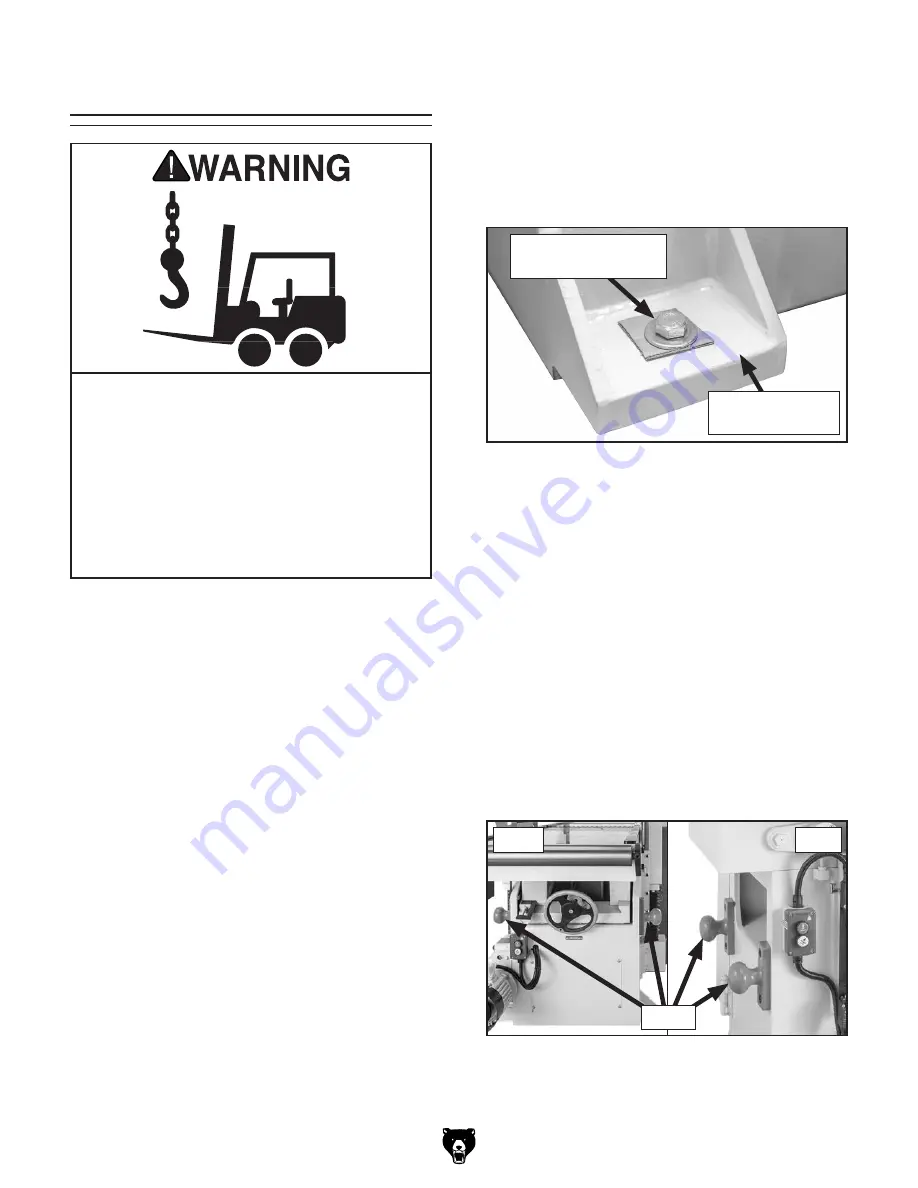

3. Remove (4) lag screws and flat wash-

ers that secure machine to shipping pallet

(see

Figure 14).

IMPORTANT: Take care not to damage

threaded holes in machine footings when

removing lag screws.

DO NOT attempt to lift or move machine without

using proper lifting equipment (such as forklift or

crane) and assistance from other people. Each

piece of lifting equipment must be rated for

at

least 7000 lbs. to support dynamic loads that

may be applied while lifting.

Review the

Power Supply section beginning on

Page 17, then prepare a permanent location for

the machine.

IMPORTANT: Make sure prepared location is

clean and level.

4. Carefully lift machine off shipping crate.

Below are two methods for performing

this operation. Use best method for your

situation.

— Secure lifting straps around (4) cleats

on machine (see

Figure 15) and attach

straps to lifting equipment with heavy-

duty shackles or other rigging equipment.

Cleats are positioned on machine to bal-

ance weight of machine when using four

lifting straps of equal length.

IMPORTANT: Eye bolts on top of motors

are for lifting the motors only. DO NOT lift

machine by eye bolts.

To lift and place machine:

1. Move machine near its prepared location

while still inside shipping crate.

2. Remove top and sides of shipping crate, then

place small items aside in safe location.

Figure 15. Location of lifting cleats.

Figure 14. Machine secured to shipping pallet.

Lag Screw and Flat

Washer (1 of 4)

Machine Footing

(1 of 4)

This is an extremely heavy machine! Serious

personal injury or death may occur if safe

lifting and moving methods are not fol-

lowed. To be safe, you will need assistance

and power equipment when moving the

shipping crate and removing the machine

from the crate. Seek assistance from a

professional rigger if you are unsure about

your abilities or maximum load ratings of

your lifting equipment.

Front

Rear

Cleats

Содержание G0841

Страница 84: ......