-68-

Model G0841 (Mfd. Since 06/18)

Squaring Headstock

The headstock is properly squared to the planer

table at the factory and should only require

adjustment if the elevation leadscrews become

misaligned. Elevation leadscrews may become

misaligned if they are not lubricated regularly,

or there is a limit switch failure and leadscrews

are driven past headstock height capacity. If you

notice the headstock binds when raising or lower-

ing, then check to see if headstock is square to

planer table.

squaring headstock

To reduce risk of shock or

accidental startup, always

disconnect and lock-out

machine from power before

adjustments, maintenance,

or service.

1. Set headstock height to 4".

2. DISCONNECT AND LOCK-OUT MACHINE

AT POWER SOURCE!

Checking/Squaring Headstock Front-

to-Rear

3. Check front and rear upper cutterhead depth-

of-cut scales.

— If scales indicate headstock height is

4", then proced to

Checking/Squaring

Headstock Side-to-Side on This Page.

— If scales indicate headstock height is not

4",

then determine which end is higher and pro-

ceed to

Step 4.

4. On end of machine where headstock is

higher, loosen (4) cap screws securing left-

side and rightside elevation leadscrew collars

(see

Figure 107).

5. Turn leftside and rightside elevation leadscrew

collars (see

Figure 107) counterclockwise

until front and rear upper cutterhead depth-

of-cut scales indicate headstock height is

even front to back. Make sure to adjust both

elevation leadscrews equally.

IMPORTANT: Turn elevation leadscrew col-

lars in measurable increments (i.e. quarter-

turns or half-turns).

6. Tighten (4) cap screws securing elevation

leadscrew collars.

7. Set headstock height. (Refer to Setting

Headstock Height on Page 70.)

Item(s) Needed:

Qty

Rotacator or Dial Indicator w/Base .................... 1

Carpenter's Square ........................................... 1

Calipers ............................................................. 1

Hex Wrench 8mm .............................................. 1

Pin or Rod 5mm Dia. ......................................... 1

checking squaring headstock front

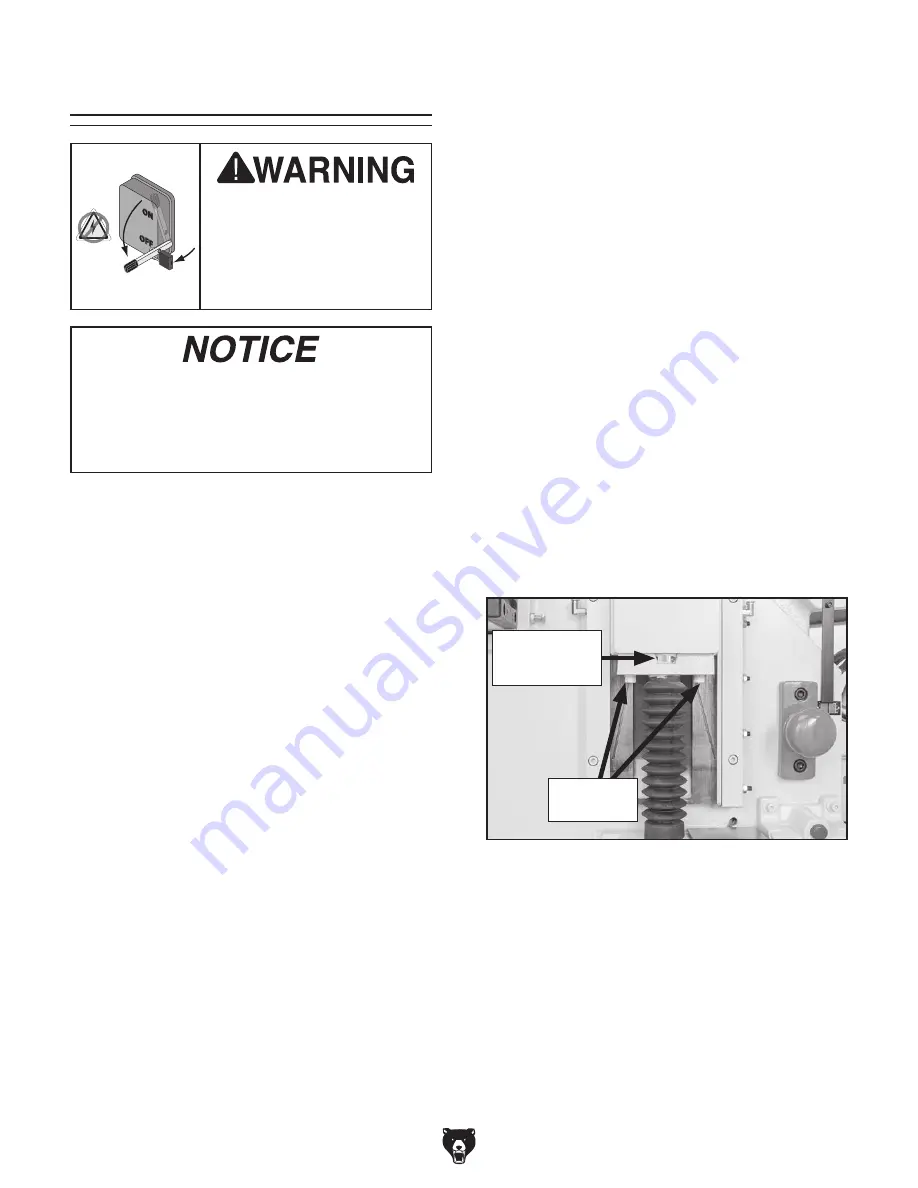

Figure 107. Location of elevation leadscrew

collar and cap screws.

Leadscrew

Collar (1 of 2)

ONLY perform the following procedures

if you are certain the headstock is out-of-

square. Attempting these procedure on an

already square headstock will cause addi-

tional misalignment.

Cap Screw

(2 of 4)

Содержание G0841

Страница 84: ......