5-62

L90 Line Current Differential System

GE Multilin

5.2 PRODUCT SETUP

5 SETTINGS

5

•

DATA LOGGER MODE

: This setting configures the mode in which the data logger will operate. When set to “Continu-

ous”, the data logger will actively record any configured channels at the rate as defined by the

DATA LOGGER RATE

. The

data logger will be idle in this mode if no channels are configured. When set to “Trigger”, the data logger will begin to

record any configured channels at the instance of the rising edge of the

DATA LOGGER TRIGGER

source FlexLogic oper-

and.

The data logger will ignore all subsequent triggers

and will continue to record data until the active record is full.

Once the data logger is full a

CLEAR DATA LOGGER

command is required to clear the data logger record before a new

record can be started. Performing the

CLEAR DATA LOGGER

command will also stop the current record and reset the

data logger to be ready for the next trigger.

•

DATA LOGGER TRIGGER

: This setting selects the signal used to trigger the start of a new data logger record. Any

FlexLogic operand can be used as the trigger source. The

DATA LOGGER TRIGGER

setting only applies when the mode

is set to “Trigger”.

•

DATA LOGGER RATE:

This setting selects the time interval at which the actual value data will be recorded.

•

DATA LOGGER CHNL 1(16):

This setting selects the metering actual value that is to be recorded in Channel 1(16) of

the data log. The parameters available in a given relay are dependent on: the type of relay, the type and number of CT/

VT hardware modules installed, and the type and number of Analog Input hardware modules installed. Upon startup,

the relay will automatically prepare the parameter list. A list of all possible analog metering actual value parameters is

shown in Appendix A:

FlexAnalog Parameters

. The parameter index number shown in any of the tables is used to

expedite the selection of the parameter on the relay display. It can be quite time-consuming to scan through the list of

parameters via the relay keypad/display – entering this number via the relay keypad will cause the corresponding

parameter to be displayed.

•

DATA LOGGER CONFIG:

This display presents the total amount of time the Data Logger can record the channels not

selected to “Off” without over-writing old data.

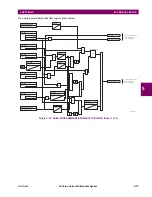

5.2.11 DEMAND

PATH: SETTINGS

PRODUCT SETUP

DEMAND

The relay measures current demand on each phase, and three-phase demand for real, reactive, and apparent power. Cur-

rent and Power methods can be chosen separately for the convenience of the user. Settings are provided to allow the user

to emulate some common electrical utility demand measuring techniques, for statistical or control purposes. If the

CRNT

DEMAND METHOD

is set to "Block Interval" and the

DEMAND TRIGGER

is set to “Off”, Method 2 is used (see below). If

DEMAND TRIGGER

is assigned to any other FlexLogic™ operand, Method 2a is used (see below).

The relay can be set to calculate demand by any of three methods as described below:

CALCULATION METHOD 1: THERMAL EXPONENTIAL

This method emulates the action of an analog peak recording thermal demand meter. The relay measures the quantity

(RMS current, real power, reactive power, or apparent power) on each phase every second, and assumes the circuit quan-

tity remains at this value until updated by the next measurement. It calculates the 'thermal demand equivalent' based on the

following equation:

(EQ 5.6)

where:

d

= demand value after applying input quantity for time

t

(in minutes)

D

= input quantity (constant), and

k

= 2.3 / thermal 90% response time.

DEMAND

CRNT DEMAND METHOD:

Thermal Exponential

Range: Thermal Exponential, Block Interval,

Rolling Demand

MESSAGE

POWER DEMAND METHOD:

Thermal Exponential

Range: Thermal Exponential, Block Interval,

Rolling Demand

MESSAGE

DEMAND INTERVAL:

15 MIN

Range: 5, 10, 15, 20, 30, 60 minutes

MESSAGE

DEMAND TRIGGER:

Off

Range: FlexLogic™ operand

Note: for calculation using Method 2a

d t

D

1

e

kt

–

–

=

Содержание UR Series L90

Страница 14: ...xiv L90 Line Current Differential System GE Multilin 0 1 BATTERY DISPOSAL 0 BATTERY DISPOSAL 0 ...

Страница 68: ...2 34 L90 Line Current Differential System GE Multilin 2 4 SPECIFICATIONS 2 PRODUCT DESCRIPTION 2 ...

Страница 138: ...4 30 L90 Line Current Differential System GE Multilin 4 3 FACEPLATE INTERFACE 4 HUMAN INTERFACES 4 ...

Страница 604: ...9 58 L90 Line Current Differential System GE Multilin 9 6 FAULT LOCATOR 9 THEORY OF OPERATION 9 ...

Страница 652: ...A 16 L90 Line Current Differential System GE Multilin A 1 PARAMETER LISTS APPENDIX A A ...

Страница 772: ...B 120 L90 Line Current Differential System GE Multilin B 4 MEMORY MAPPING APPENDIX B B ...

Страница 802: ...C 30 L90 Line Current Differential System GE Multilin C 7 LOGICAL NODES APPENDIX C C ...

Страница 812: ...D 10 L90 Line Current Differential System GE Multilin D 1 IEC 60870 5 104 APPENDIX D D ...

Страница 824: ...E 12 L90 Line Current Differential System GE Multilin E 2 DNP POINT LISTS APPENDIX E E ...

Страница 834: ...F 10 L90 Line Current Differential System GE Multilin F 3 WARRANTY APPENDIX F F ...

Страница 846: ...xii L90 Line Current Differential System GE Multilin INDEX ...