REGENERATIVE

SINUS PENTA

APPLICATION

70/

140

0

1

2

3

4

7) Possible

failures:

If no failure occurred, go to step 8; otherwise, check links to the drive and check if alarm

messages are displayed. The start screen shows the value of the DC-bus voltage (M501);

before closing the ENABLE, this measure should be more or less equal to the mains voltage

(M502) multiplied by 1.41; after closing the ENABLE, this value should tune to the setpoint

in P500.

8) Additional

parameter

alterations:

Note that you can change Cxxx parameters in the CONFIGURATION menu only when the

drive is DISABLED.

We suggest that you write down any custom parameter. Parameters that may need

alterations are C503 (enabling mode of MDO4 relay for motor drive activation) and C502

(alarms relating to the supply mains).

9) Alarm reset:

If an alarm trips, find the cause responsible for the alarm and reset the equipment: enable

MDI3 input (terminal 16) for some time, or press the RESET key in the display/keypad.

10) Motor

drive starting:

Start up the motor drive as described in the Installation Instructions manual. When the

motor drive is operating, make sure that the DC-bus voltage (displayed in the Measure

submenu) is kept approx. constant and equal to the setpoint; also make sure that the mains

is stable. If load variations strongly affect DC-bus voltage or if it is unsteady, adjust the

voltage regulator parameters (P510 to P515).

If overvoltage alarms trip, do the following:

1)

For the regenerative drive sizes provided with a built-in braking unit (up to S30

included), you can install a braking resistor between power terminals 47+ and 48B

of the regenerative drive.

2)

For the regenerative drive sizes which are not provided with a built-in braking unit

(size > S30), you can use the external braking unit BU200. Configure BU200 with a

trip voltage higher than the bus setpoint of the regenerative drive (P500) but lower

than the overvoltage value.

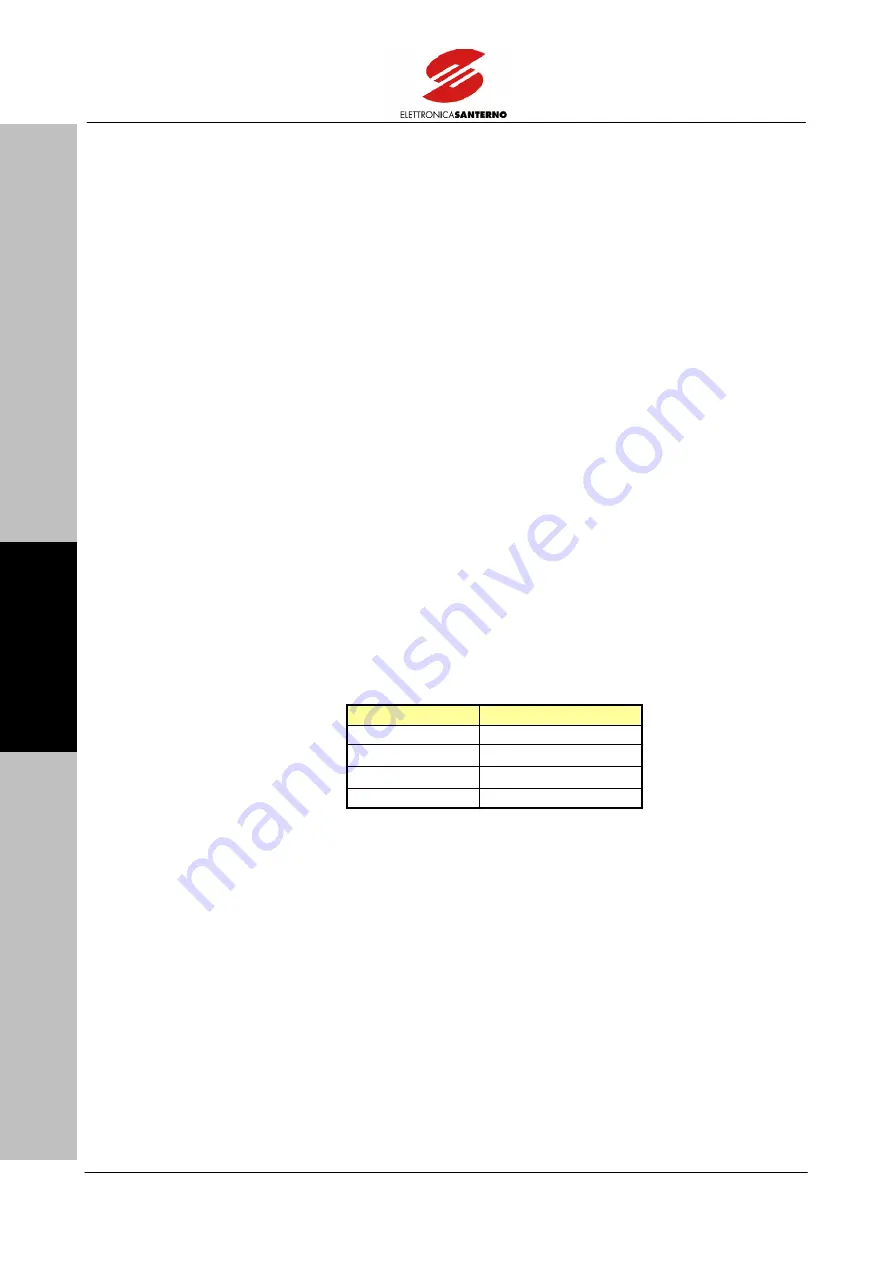

Voltage Class

Overvoltage Threshold

2T 443.3

4T 828.7

5T 994.4

6T 1198.2