SINUS PENTA

REGENERATIVE

APPLICATION

129/

140

0

1

2

3

4

3.15.

RESISTOR BRAKING MENU

3.15.1.

O

VERVIEW

A braking resistor connected between power terminals 47+ and 48 B of the regenerative drive can be used

for the RGN drive sizes provided with a built-in braking unit (up to size S30 included). The braking resistor is

used only when regeneration can cause overvoltage faults in the regenerative drive.

This menu allows setting the max. duty-cycle of the drive braking resistor.

The maximum allowable duty-cycle of the braking resistor is set through parameters C211 [Max. Continuous

Operation Time (Ton)] and C212 [Max. Duty- cycle (100 * Ton / (Ton+Toff) [%] )]. If Ton = C212, when the

time set is over, the respective command is disabled for a time equal to Toff = (100 – C211) * C212 / C211

[sec].

3.15.2.

L

IST OF

P

ROGRAMMABLE

P

ARAMETERS

C211

AND

C212

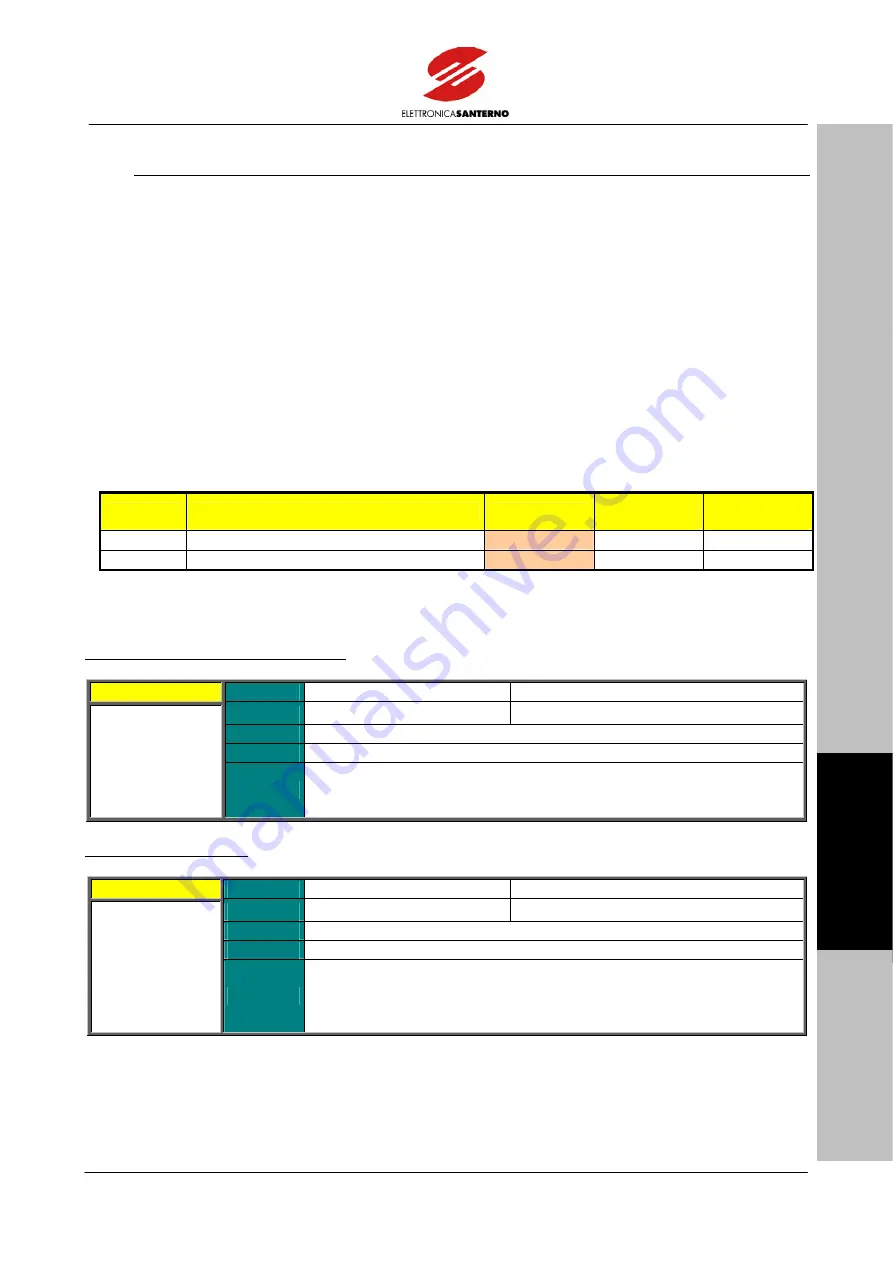

Parameter

FUNCTION

User Level

MODBUS

Address

DEFAULT

VALUES

C211

Max. Continuous Operation Time

ENGINEERING

1211 2000

sec

C212

Braking Duty-cycle

ENGINEERING

1212 10%

Table 23: List of parameters C211 and C212.

C211 Max. Continuous Operation Time

C211

Range

0 ÷ 32000

0 ÷ 32000 msec

Default

2000

2000 sec

Level

ENGINEERING

Address

1211

Function

This parameter sets the max. continuous operation time for the braking

resistor. If the braking resistor is used for the time set in C211, the relevant

command is disabled for the rest time set in C212.

C212 Braking Duty-cycle

C212

Range

0 ÷ 100

0 ÷ 100 %

Default

10

10%

Level

ENGINEERING

Address

1212

Function

C212 = (Ton/(Ton+Toff))*100

This parameter sets the allowable duty-cycle for the braking resistor. It is

expressed as a percentage and sets the rest time of the braking resistor

after its max. continuous operation time set in C211.