Pump End 5–4

Lobes Worn Smooth.

Old age is the most common reason for smooth wear. The average

life of a stator operating in a single-family home (300 gpd) is about 10 years. Higher incoming

flows will shorten the life of the stator. If two homes are on the same station, the stator will last

about five years. However, if the stator has worn prematurely (less than six years for a single-

family home), abrasives cause the wear.

Look into the void between the inner skirt and the outer bore of stator. Check for an

accumulation of more than 1/8 inch of any of these types of materials: sand, goldfish stones,

gravel, kitty litter, glass, etc.

Determine and eliminate the source of the abrasives or the stator will fail prematurely. Check

for infiltration from a broken line, a sump or even a roof drain. Additionally, ensure that the

homeowner is not introducing the abrasive materials through a toilet or sink.

Lobes Worn Rough.

A pump that has run dry is the most common reason for lobes that have

worn rough. To determine the cause of a pump running dry:

1.

Check to see if the Equalizer tube is plugged.

2.

Check the tank vent. Ensure the vent is clear and installed properly.

3.

Check the sensing line to ensure it is clear. Visually inspect the sensing line for

blockage.

4.

Check for an obstruction at the suction end of the pump (inlet shroud). An obstruction

will restrict the flow. Check for objects such as a board, junction box cover, heavy

glove or plate.

5.

Inspect and troubleshoot the electrical controls. Refer to

Chapter 9 – Control Cavity

.

6.

Check the push-to-run/redundant run circuit. Check the push-to-run circuit for all

units with this feature.

7.

Check for shorts in the panel, tray cable, EQD and control compartment. Two wires

touching, corrosion or water can cause shorts. Refer to

Chapter 2 – Troubleshooting

.

Swollen Pump Stator

Petroleum-based products such as paint thinner, photo-developing chemicals, gas, oil, brake

fluid, transmission fluid, etc. will cause a swollen pump stator; introduction of these types of

products into the system must be eliminated or the problem will reoccur. The pump stator is

made of EPDM material, which absorbs petroleum the way a sponge absorbs water. If the

pump stator appears to have no wear but will not pump liquid, compare it to a new stator.

Slide the old stator over the pump rotor and remove it. Slide the new stator over the rotor and

remove it. If the new stator fits tighter or if the old stator appears larger than the new one, the

pump stator needs to be replaced.

Note:

Never intentionally introduce petroleum based-products to a public sewer system. If they are

present, contact your local distributor and ask for an oil-resistant stator, service PT# 8005.

This stator is not recommended for normal residential conditions because of reduce life

expectancy (average of 2 to 3 years).

Содержание Extreme Series

Страница 1: ...Service Manual E One Extreme Grinder Pumps 240V 60 Hz Hardwired Controls...

Страница 2: ......

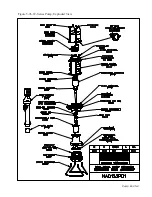

Страница 32: ...Pump End 5 8 Figure 5 9a D Series Pump Exploded View...

Страница 33: ...Pump End 5 9 Figure 5 9b W Series Pump Exploded View...

Страница 34: ...Pump End 5 10 Figure 5 9c Gatorgrinder GH Series Pump Exploded View...

Страница 35: ...Pump End 5 11 Figure 5 9d IH091 Pump Exploded View...

Страница 36: ...Pump End 5 12...

Страница 58: ...Level Sensor 8 10 Figure 8 35 Level Sensor Assembly Exploded View all hardwired pumps...

Страница 70: ...Mechanical Seal Assembly 11 2...

Страница 75: ......