E-DWT-10000-AF OPERATION AND MAINTENANCE MANUAL

© 2008 DH Instruments, a Fluke Company

Page 10

2.2

SITE REQUIREMENTS

Install E-DWT-10000-AF on a flat, stable surface at a convenient height. If using the battery/charger

pack, consider its placement.

When used with its battery/charger pack, E-DWT-10000-AF requires no external support facilities. If not

using the battery, an electrical power source of 100 to 240VAC, 50-60 Hz is required.

2.3

SETUP

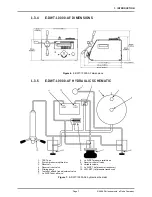

2.3.1

PREPARING FOR OPERATION

To prepare E-DWT-10000-AF for check out and operation:

Remove the protective plastic sheet from the front panel display.

Familiarize yourself briefly with the E-DWT front and real panels and controls (see

Section

1.3.1

).

Connect the 12 VDC power supply pack to a source of 100 to 240V, 50-60 Hz AC power

and to the 12 VDC connection on the rear of the E-DWT; or, use the battery/charger pack

and cable if battery has been charged (see Section 3.3).

Connecting power causes the RPM4-E-DWT to power up.

Observe the front panel display as the RPM4-E-DWT initializes, error checks and goes to

the MAIN RUN screen (see Section 3.6.1). If the RPM4-E-DWT fails to reach the main

run screen, service is required. Record the sequence of operations and displays

observed and contact a

DHI

Authorized Service Provider (see Section 1, Table 25).

Check that one of the two green Valve Status LEDs on the front of the E-DWT is lit (the

red LED should NOT be ON). If neither of the green LEDs lights, check that the 12 pin

circular connector on the rear panel of the RPM4-E-DWT itself is properly connected to

the J1 ACC. connector.

Install the four variable volume handles into the variable volume hub on the front of the E-DWT.

Leave the stainless steel plug in the top surface TEST port. Check that the gland holding

the plug is tight.

Check/Set Security Level

RPM4-E-DWT has a security system based on user levels. By default, the security

system is set to “low”, which includes access restriction to internal calibration coefficients,

and there is no password required to change the security level. See Section 3.9.5.5 for

information on the security level system. As part of the RPM4-E-DWT startup, determine

the security level that is appropriate for the RPM4-E-DWT and set a password if desired.

RPM4-E-DWT is delivered with the security level set to “low” to avoid inadvertent altering of

critical internal settings but with access to changing security levels unrestricted. It is recommended

that the low security level be maintained at all times and password protection be implemented if

control over setting of security levels is desired.

2.3.2

SETTING UP AUTOTEST FILES

E-DWT’s RPM4-E-DWT supports automated test/calibration sequences. AutoTest sequence

parameters for testing specific DUTs can be stored in File AutoTest files and recalled to run a

test. Consider setting up File AutoTest files for frequently tested DUTs as part of the E-DWT

set up process (see Section 3.1.3).

Содержание E-DWT-10000-AF

Страница 10: ...E DWT 10000 AF OPERATION AND MAINTENANCE MANUAL 2008 DH Instruments a Fluke Company Page VIII N NO OT TE ES S...

Страница 18: ...E DWT 10000 AF OPERATION AND MAINTENANCE MANUAL 2008 DH Instruments a Fluke Company Page 8 N NO OT TE ES S...

Страница 24: ...E DWT 10000 AF OPERATION AND MAINTENANCE MANUAL 2008 DH Instruments a Fluke Company Page 14 N NO OT TE ES S...

Страница 102: ...E DWT 10000 AF OPERATION AND MAINTENANCE MANUAL 2008 DH Instruments a Fluke Company Page 92 N NO OT TE ES S...

Страница 128: ...E DWT 10000 AF OPERATION AND MAINTENANCE MANUAL 2008 DH Instruments a Fluke Company Page 118 N NO OT TE ES S...

Страница 130: ...E DWT 10000 AF OPERATION AND MAINTENANCE MANUAL 2008 DH Instruments a Fluke Company Page 120 N NO OT TE ES S...

Страница 132: ...E DWT 10000 AF OPERATION AND MAINTENANCE MANUAL 2008 DH Instruments a Fluke Company Page 122 N NO OT TE ES S...