VLT

®

6000 HVAC

MG.60.B1.02 - VLT is a registered Danfoss trademark

10

■

■

■

■

■

Better regulation

If a frequency converter is used for regulating the flow

or pressure of a system, improved regulation is

obtained which can be adjusted very precisely.

A frequency converter can vary the speed of the fan or

pump infinitely, thereby obtaining infinitely variable

control of flow and pressure.

Furthermore, a frequency converter can quickly

regulate the speed of the fan or pump, so as to adapt

it to new flow or pressure conditions in the system.

More traditional, mechanical flow or pressure

regulating systems tend to provide slow, inaccurate

regulation if compared with that of the frequency

converter.

■

■

■

■

■

Frequency converters generate less noise

If the speed of a fan is changed, the sound level

changes, too. If the rpm figure is reduced by 50%

from the rated rpm value, the sound level will go down

by approx. 16 dB(A).

The formula is:

55 log x ( ) = dB(A)

■

■

■

■

■

Simpler installation when using a frequency con-

verter

A frequency converter can replace a traditional

regulating system, in which mechanical dampers and

valves are used for regulating flow or pressure.

The great advantage involved in using a frequency

converter is that the system becomes simpler, since a

lot of the mechanical and electrical equipment is no

longer required.

■

■

■

■

■

V-belts no longer required

In mechanical regulating systems, where the fan is

driven by V-belts, it is necessary to change belt

pulleys in order to adjust the fan speed to match the

neces-sary maximum load. Using a frequency conver-

ter, the V-belts can be replaced by directly driven mo-

tors, whose speed is changed simply by means of the

frequency converter.

The efficiency of the system improves and the entire

installation takes up less space. There is no dust from

the V-belt and less maintenance.

■

■

■

■

■

Regulating dampers and valves no longer

required

Since the flow or pressure can be regulated by

means of the frequency converter, no regulating

dampers and valves are required in the system.

■

■

■

■

■

Cos

ϕϕϕϕϕ

compensation

Generally speaking, a frequency converter with a cos

of 1 provides power factor correction for the cos

ϕ

of

the motor, which means that there is no need to

make allowance for the cos

ϕ

of the motor when

sizing the power factor correction unit.

■

■

■

■

■

Star/delta starter or soft-starter not required

When larger motors are started, it is necessary in

many countries to use equipment that limits the

start-up current. In more traditional systems, a star/

delta starter or soft-starter is widely used. Such

motor starters are not required if a frequency conver-

ter is used.

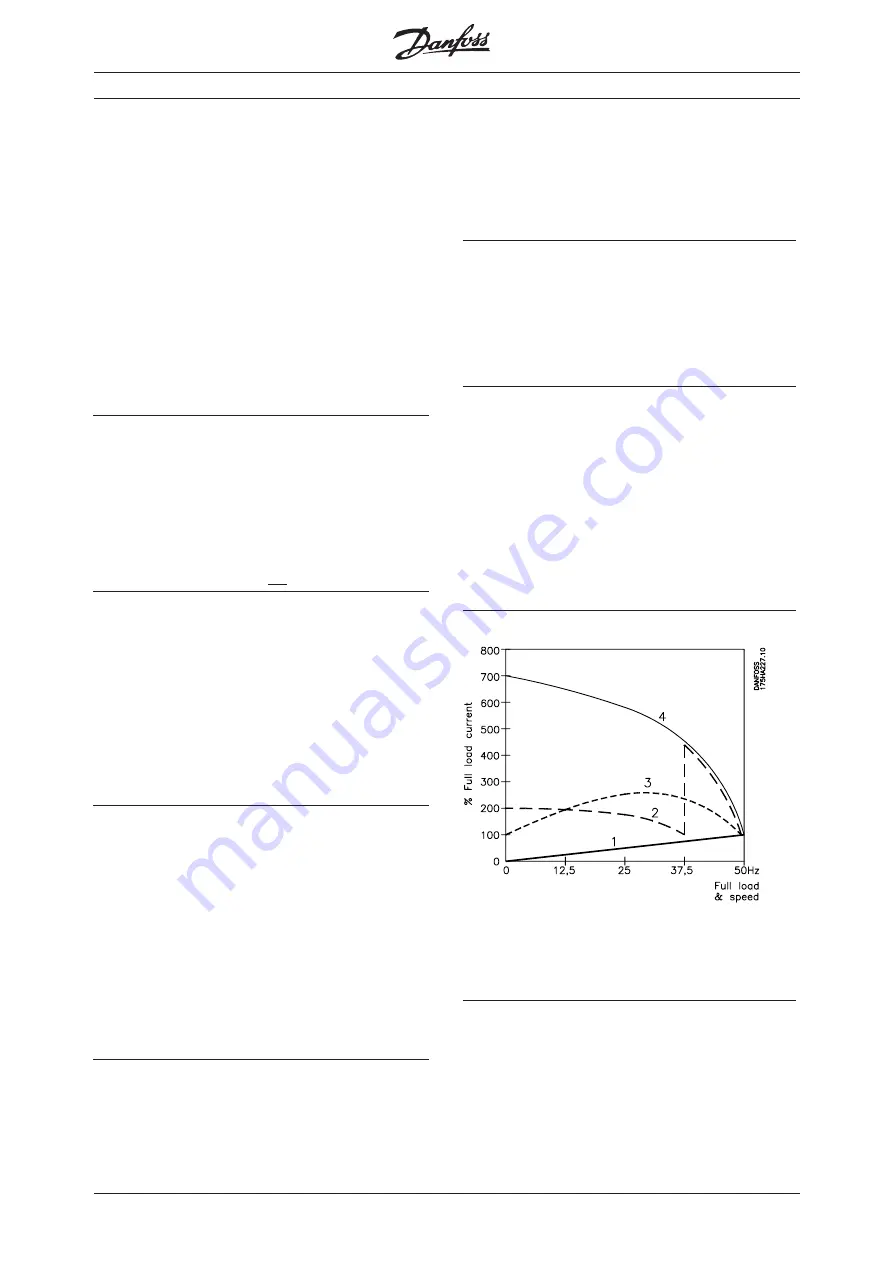

As illustrated in the figure below, a frequency conver-

ter does not consume more than rated current.

1 = VLT 6000 HVAC

2 = Star/delta starter

3 = Soft-starter

4 = Start directly on mains

■

■

■

■

■

Cost of using frequency converter not higher

The example on the following page shows that a lot

of equipment is not required when a frequency

converter is used. It is possible to calculate the cost

of installing the two different systems. In the example

on the following page, the two systems can be

established at roughly the same price.

n

1

n

2