16

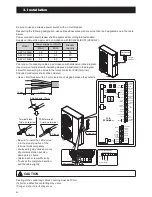

3. Installation

Connection to the water circuit

1)

Connect the water supply to a drain and fill valve.

2)

Loosen the plug a little to take the air out of the circulating water pipe through the air purge valve. The plug

doesn't have to be removed. Be careful not to loose it.

3)

Fill with water until the manometer indicates a pressure of approximately 2.0 bar. Remove air in the circuit as

much as possible using the air purge valves.

4)

After the air is all purged from the system, tighten the plug again.

• Water connections must be made in accordance with diagram in the manual and on the unit, respecting the water

in-and outlet.

CAUTION

• Be careful not to deform the unit piping by using excessive force when connecting. Deformation of the piping can

cause the unit to malfunction.

If air, moisture or dust gets in the water circuit, problems may occur. Therefore, always take into account the

following when connecting the water circuit:

• Use clean pipes only.

• Hold the pipe end downwards when removing burrs.

• Cover the pipe end when inserting it through a wall so that no dust and dirt enter.

• Use a good thread sealant for the sealing of the connections. The sealant must be able to withstand the

pressures and temperatures of the system.

• When using non-brass metallic piping, make sure to insulate both materials from each other to prevent galvanic

corrosion.

• Because brass is a soft material, use appropriate tooling for connecting the water circuit. Inappropriate tooling will

cause damage to the pipes.

• The unit is the only to be used in a closed water system. Application in an open water circuit can lead to

excessive corrosion of the water piping.

Before continuing the installation of the unit, check the following points:

• The maximum water pressure is 3 bar.

• Make sure to provide a proper drain for the pressure relief valve to avoid any water coming into contact with

electrical parts.

• Air vents must be provided at all high points of the system. The vents should be located at points which are easily

accessible for servicing. An automatic air purge is provided inside the unit. Check that this air purge valve is not

tightened too much so that automatic release of air in the water circuit remains possible .

• Take care that the components installed in the field piping can withstand the water pressure.

• Never use Zn-coated parts in the water circuit. Excessive corrosion of these parts may occur as copper piping is

used in the unit’s internal water circuit.

loosen

tighten

Air purge valve

Plug

Charging water

Содержание AEYC-0639U-CH

Страница 156: ...20810030 M ...