Cambridge Air Solutions

86

S-Series Technical Manual

Problem

Possible Cause

Corrective Action

VI. HIGH LIMIT TRIPPED

1. High Limit

a) High limit will not reset

a) Replace high limit.

2. Unit Overfiring

a) Manifold pressure too high

a) Adjust appliance regulator to obtain

temperature rise specified on nameplate.

3. Discharge Damper

a) Damper blades partially closed

b) Defective damper motor

a) Adjust damper stroke length.

b) Replace damper motor.

4. Low Airflow

a) Blower running backwards

b) Belts slipping

c) Blocked intake or discharge

a) Reverse motor direction.

b) Tighten or replace belts.

c) Find and remove obstruction.

5. Temperature Control System

a) Temperature control system does not

modulate

a) See problem VIII (page 86).

VII. BLOWER RUNS;

UNIT HEATS;

WILL NOT CYCLE

OFF

1. Operating Thermostat

a) Short in thermistor circuit

b) Thermostat located improperly

c) Thermostat differential setting too wide

d) Defective thermostat

a) Check thermistor wiring and/or replace

thermistor.

b1) Thermostat in cold draft-relocate.

b2) Thermostat not satisfied-turn down.

c) Reduce differential setting.

d) Replace thermostat.

2. Burner Service Switch

a) Switch in LOCAL position

a) Place switch in REMOTE position.

3. Auxiliary Control

a) Auxiliary contacts closed

a) Check auxiliary circuit wiring and

contacts.

4. Misunderstood Control System

Operation

a) Control system doesn’t function as

expected

a) Review control system operational

characteristics.

VIII. MODULATING

VALVE DOES NOT

MODULATE;

CONTINUOUS

HIGH FIRE

1. Amplifier (A1014 or A1044 or AD1014)

a) Wire not connected to amplifier terminal

3 or 4. Also terminal 5 on A1044

amplifier

b) Jumper not installed between terminals 2

and 3 of A1014 or AD1014

c) Defective amplifier

a) Reinstall wire.

b) Reinstall jumper.

c) Replace amplifier.

2. Discharge Temperature Sensor

(TS114J or TS144)

a) Discharge Air Temperature Sampling

Tube clogged

b) Open in sensor circuit

c) Sensor cross-wired to amplifier

d) Temperature Control System out of

calibration

a) Clean Discharge Air Temperature

Sampling Tube (page 69).

b) Replace the sensor if the resistance

measured at terminals 1 and 2 on TS114J

sensor exceeds 15,000 Ω 1 and 3 or 2 and

3 on TS144 exceeds 6,000 Ω.

c) Correct wiring terminations.

d) Perform appropriate calibration procedure

(pages 60–62).

TROUBLESHOOTING INSTRUCTIONS

TROUBLESHOOTING GUIDE

Содержание S Series

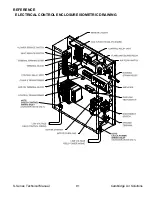

Страница 93: ...S Series Technical Manual 91 Cambridge Air Solutions REFERENCE ELECTRICAL CONTROL ENCLOSURE ISOMETRIC DRAWING ...

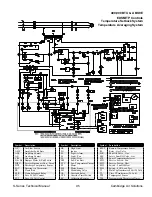

Страница 100: ...Cambridge Air Solutions 98 S Series Technical Manual REFERENCE BUILDING AUTOMATION SYSTEM ...

Страница 112: ...Cambridge Air Solutions 110 S Series Technical Manual MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 113: ...MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 114: ...Cambridge Air Solutions 112 S Series Technical Manual ...

Страница 116: ...760 Long Road Crossing Dr Chesterfield MO 63005 Phone 636 532 2233 800 899 1989 Fax 636 530 6133 www cambridgeair com ...