Cambridge Air Solutions

106

S-Series Technical Manual

HIGH PRESSURE REGULATOR (HPR)

The HPR option is required when the

gas supply pressure exceeds the

nameplate rating for the heater.

Unless otherwise specified, the HPR

assembly is also furnished with a high

gas pressure manual shut-off valve

and a tap for measuring the upstream gas pressure. The

HPR must be a positive lock-up type regulator which

must be vented to outdoors. It is sized according to the

gas supply pressure and the capacity requirements of

the heater.

INTERMITTENT/CONTINUOUS CONTROL

The Intermittent/Continuous Control allows the burner

input to be modulated to be operated continuously at

modulating discharge temperature for make-up air (see

EDSM on page 68) or operated intermittently based on

a thermostat at maximum discharge temperature (see

EDL on page 68) for space heating.

Requires EDSM controls and a signal to switch

between modes (Exhaust Fan Interlock, Temperature

Setback System, Manual Make-Up Air Switch, etc.)

IGNITER (IG)

The hot surface igniter is the

ignition source for lighting the gas

in the burner. It is made of silicon

carbide which is very fragile. Care

should be used in handling. It

operates on 24 Volts and the current

ranges from 1.3 to 1.7 amps. It will reach temperatures

in excess of 2400˚F during the ignition trial. It is

furnished with a vinyl sleeve for shock mounting and

sealing in the mounting tube.

LEAK TEST FACILITY (SW4)

The leak test facility is provided on

all heaters over 400,000 Btu/hr. It

consists of a momentary switch for

the shut-off valve (SOV) in the gas

train and a gauge port between the

(SOV) and (SSV) shut-off

valve. By holding the gas valve

momentary switch closed, the (SOV)

gas valve is energized which allows

gas pressure to build on the seat of

the SSV safety shut-off gas valve.

The gauge port between valves is

used to determine if the SOV shut-off gas valve seat is

properly sealed.

MANIFOLD PRESSURE REGULATOR

The manifold pressure regulator

controls the burner manifold

pressure. When the MR212 valve is

used, this modulating valve also

serves as the manifold pressure

regulator. The maximum gas supply

pressure rating is normally

determined by the exposed pressure rating of the

regulating device. RV61 and RV81 regulators are rated

at 1 psig; and the MR212 is rated at 5 psig. (For units

rated at 400,000 Btu/hr or below, see the combination

valve below.)

MODULATING VALVE (MV)

The MV responds to a 4 to 24 Volt

DC signal from the amplifier to

modulate the flow of gas to the

burner. On the M511 or M611

valve, the low fire adjusting screw is

located on the far side of the valve

under the dust cover. On the MR212 valve, the low fire

adjusting screw is located under the large dust cover.

The MR212 modulating valve also serves as the

manifold pressure regulator.

REMOTE HEAT ADJUSTMENT (RHA)

As discussed under the component

description for the EDR control

system, the RHA may have a single

or dual adjusting knob(s) on the dial

face. The single adjusting knob

control permits manual adjustment

of the discharge air temperature

from 55 to 130˚F. The override

temperature selector dial which is visible from the top

of the RHA control, increases the discharge

temperature above the setting on the dial face by the

increment selected when a jumper or switch contact is

provided across terminals 20 and 22.

Heaters which are specified with a temperature rise

above 130˚F are supplied with dual adjusting knobs on

the dial face of the RHA. This control permits manual

adjustment of the discharge temperature from 55 to

105˚F or 120 to 160˚F. A jumper or switch contact

is required across terminals 20 and 22 to activate the

higher temperature selection.

Содержание S Series

Страница 93: ...S Series Technical Manual 91 Cambridge Air Solutions REFERENCE ELECTRICAL CONTROL ENCLOSURE ISOMETRIC DRAWING ...

Страница 100: ...Cambridge Air Solutions 98 S Series Technical Manual REFERENCE BUILDING AUTOMATION SYSTEM ...

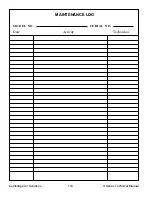

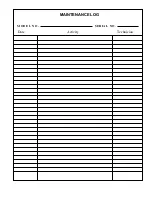

Страница 112: ...Cambridge Air Solutions 110 S Series Technical Manual MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 113: ...MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 114: ...Cambridge Air Solutions 112 S Series Technical Manual ...

Страница 116: ...760 Long Road Crossing Dr Chesterfield MO 63005 Phone 636 532 2233 800 899 1989 Fax 636 530 6133 www cambridgeair com ...