S-Series Technical Manual

57

Cambridge Air Solutions

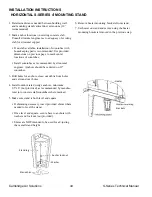

f. Remove the cap (A) exposing the minimum fire

adjusting screw. Turn the adjusting screw (B) to

obtain the desired minimum fire setting.

g. Replace the cap (A).

On the MR212 modulating/regulating valve,

tighten the lock screw (C) and replace the housing

cover.

h. Turn blower and burner service switches to the

“OFF” position.

i. Reconnect the wire to terminal #8 on the amplifier.

j. When performing a start-up proceed to the next

step, otherwise perform Final Heater Preparation

(page 59).

8. CALIBRATION CHECK

The discharge temperature control system has been

calibrated at the factory to the specified airflow, static

pressure, and temperature rise. The actual operating

conditions may require minor adjustments to the con-

trol settings to ensure the heater functions within the

operating parameters of its listing.

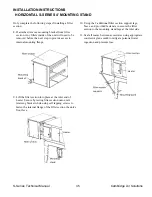

a. Remove the cover of the discharge air temperature

sampling box. Refer to the Heater Configuration

(page 4) for the discharge air temperature sam-

pling box location, and the Individual Component

Description Section (page 67) for additional infor-

mation. Install a thermocouple in the grommet

inside the discharge air temperature Sampling Box,

and then reinstall the cover. Route the thermocouple

wire to a meter located outside of the unit.

b.1. On EDL control systems, the discharge tempera-

ture should match the temperature shown on the

dial located on the amplifier. The dial should be

set to 160°F.

b.2. On EDSM and EDSM/TP control systems, the

discharge temperature should match the tempera-

ture shown on the MAX dial on the amplifier

when the Space Temperature Selector (STS) is set

to its highest setting. If the space temperature is

warm, a test resistance of 7,500 ±250 Ω should be

con-nected in the circuit in place of the STS. The

MAX dial on the amplifier should be set to 160°F.

b.3. On EDR control systems, jumper terminals

20 and 22 and turn the dial on the remote heat

adjust RHA to its highest setting to utilize the

full temperature range of the control system. On

heaters with a single temperature selection dial

on the face of the control (Maxitrol part number

TD114), set the dial to 90°F and verify that the

override temperature selector dial, which is visible

from the top of the control, is set at 40°F. The

combination of these two settings should control

the discharge tempera-ture to 130°F. On heaters

with dual temperature selection dials on the face

of the control, set the Space Heat dial to 160°F.

b.4.1. For EDSC control systems, verify the

Maximum Discharge Air Limit Range and the

Minimum Discharge Air Limit Range jumper

settings.

MAX DA LIMIT RANGE SETTINGS

MIN DA LIMIT RANGE SETTINGS

Содержание S Series

Страница 93: ...S Series Technical Manual 91 Cambridge Air Solutions REFERENCE ELECTRICAL CONTROL ENCLOSURE ISOMETRIC DRAWING ...

Страница 100: ...Cambridge Air Solutions 98 S Series Technical Manual REFERENCE BUILDING AUTOMATION SYSTEM ...

Страница 112: ...Cambridge Air Solutions 110 S Series Technical Manual MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 113: ...MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 114: ...Cambridge Air Solutions 112 S Series Technical Manual ...

Страница 116: ...760 Long Road Crossing Dr Chesterfield MO 63005 Phone 636 532 2233 800 899 1989 Fax 636 530 6133 www cambridgeair com ...