Cambridge Air Solutions

84

S-Series Technical Manual

Problem

Possible Cause

Corrective Action

II. BLOWER RUNS;

NO HEAT;

FLAME SAFETY

RELAY DOESN’T

LOCK OUT

1. Mode Selector Switch

a) Switch in VENT position

b) Defective Switch

a) Place switch in HEAT position.

b) Replace switch.

2. Burner Service Switch

a) Switch in OFF position

b) Defective switch

a) Place switch in REMOTE position.

b) Replace switch.

3. Multi-Functional PC Board

a) No input voltage on Terminal W (RCS)

b) Inlet temperature above EAT setpoint

c) Improper wiring

d) Defective board

a) Check voltage in RCS.

b) Adjust EAT setpoint.

c) Check wiring.

d) Replace multi-functional PC board.

4. Airflow Switch

a) Blower running backwards

b) Belts slipping

c) Blocked intake or discharge

d) Clogged airflow tubing or pickup ports

e) Defective switch

a) Reverse motor direction.

b) Tighten and/or replace belts.

c) Find and remove obstruction.

d) Clean or replace tubing or pickup ports.

e) Replace switch.

5. Flame Safeguard Relay

a) No input voltage

b) Defective FSR

a) Check wiring.

b) Replace FSR.

III. BLOWER RUNS;

NO HEAT;

FLAME SAFETY

RELAY LOCKS OUT

1. Igniter

a) No current (open igniter)

b) No voltage

During trial for ignition:

a) Check igniter current.

b) Check FSR output to igniter.

2. High Limit

a) High limit tripped

a) See Problem Number VI (page 86).

3. High or Low Gas Pressure Switches

a) Low gas pressure switch tripped

b) High gas pressure switch tripped

c) Defective gas pressure switch

a) Check gas supply for low gas pressure or

no gas.

b1) Check manifold gas pressure for high

pressure reading and reset pressure

regulator.

b2) Check gas supply pressure against name

plate.

b3) Verify the high pressure regulator is a

lock-up type.

c) Replace gas pressure switch.

4. Gas Valve

a) No input voltage

b) Gas valve does not open

c) Defective solenoid

a1) Check FSR output to R1 relay

during ignition trial.

a2) Check gas valve circuit and wiring.

b1) Compare supply voltage to nameplate

voltage.

b2) Clean and/or replace gas valve parts.

c) Replace solenoid or valve assembly.

5. Modulating Valve

a) Minimum fire set too low

a) Adjust minimum fire on modulating valve.

6. Multi-Functional PC Board

a) Low fire start set too low

b) Thermistor open or not connected

a) Adjust modulating valve voltage between

10 and 13 Volts DC.

b) Properly install or replace thermistor.

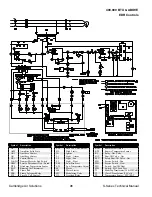

TROUBLESHOOTING INSTRUCTIONS

TROUBLESHOOTING GUIDE

Содержание S Series

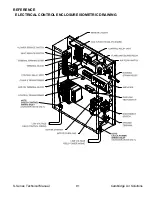

Страница 93: ...S Series Technical Manual 91 Cambridge Air Solutions REFERENCE ELECTRICAL CONTROL ENCLOSURE ISOMETRIC DRAWING ...

Страница 100: ...Cambridge Air Solutions 98 S Series Technical Manual REFERENCE BUILDING AUTOMATION SYSTEM ...

Страница 112: ...Cambridge Air Solutions 110 S Series Technical Manual MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 113: ...MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 114: ...Cambridge Air Solutions 112 S Series Technical Manual ...

Страница 116: ...760 Long Road Crossing Dr Chesterfield MO 63005 Phone 636 532 2233 800 899 1989 Fax 636 530 6133 www cambridgeair com ...