S-Series Technical Manual

15

Cambridge Air Solutions

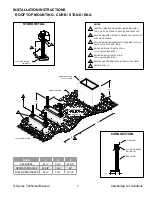

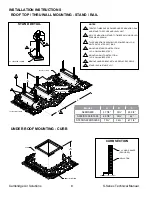

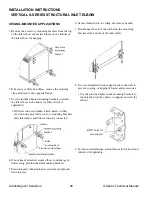

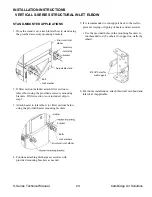

INSTALLATION INSTRUCTIONS

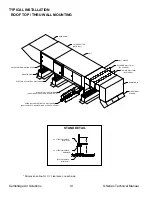

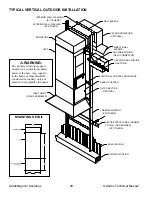

UNDER ROOF MOUNTING

m

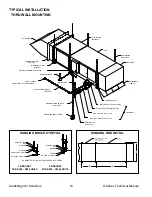

WARNING:

Due to the size and weight of this equipment, it

is recommended the heater mounting structure be

reviewed and approved by a qualified structural

engineer and the roof manufacturer before

installing this equipment.

IMPORTANT

Before proceeding with the installation, verify the

feasibility of the location selected with respect to ac-

cessibility to the equipment for service and mainte-

nance functions.

m

CAUTION

To prevent contaminated air from being drawn

into the heater, install the heater’s inlet at least 10

feet from any building exhaust, process exhaust,

sewer stacks, or other sources that would allow

contaminants to be drawn into the heater. Consult

local codes for additional references.

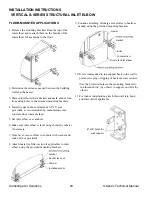

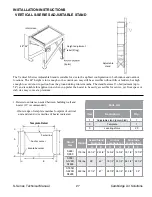

1. Prepare roof penetration to the dimensions below.

See page 7 for Under Roof Mounting - Curb draw-

ing

IMPORTANT

Accurate measurements are critical and will affect

the installation process. Verify that the roof opening

aligns with the curb opening.

2. Install the mounting curb and the mounting struc-

ture per the structural engineer and roof manufac-

turer’s recommendations.

IMPORTANT

The mounting curb or mounting structure should

be installed such that the heater’s inlet plenum will

mount level.

3. Seal all roof penetrations to prevent roof leaks.

4. Lower the inlet duct through the mounting curb

and the roof opening.

5. Secure the inlet plenum to the curb.

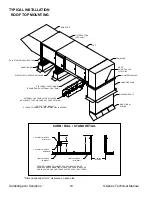

6. Connect inlet accessories to the heater including

filter section (optional) and inlet elbow prior to

lifting the heater in place.

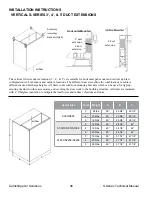

7. Install hanging rods to adequate ceiling supports

and align with the hanging brackets on the heater.

Refer to hanging rod size shown on table below.

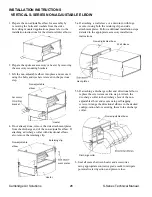

8. Remove the lag bolts used to fasten the unit to the

skid. Do not remove the hanging brackets from the

side of the heater. On S400/S800 model heaters,

rotate the hanging brackets 180˚, and retighten the

securing hardware.

9. Use a forklift or comparable lifting device to

raise and position the heater. Take precautions

to prevent equipment damage (dents and/or

scratches) when the heater is being lifted into

position.

10. Use washers and double lock nuts to secure

equipment on the hanging rods.

11. Install the directional elbows. Consult the job

layout for the orientation of the elbows.

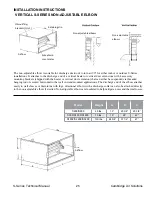

Weight

Hanging Rods

Roof Opening**

Model

Qty.

Size

A

B*

C

L

W

S400/S800

550 lbs.

4 (6*)

3/8” dia.

57 7/8”

33¼”

27 7/8”

25”

25”

S950/S1200/S1600

800 lbs.

4 (6*)

3/8” dia.

69 7/8”

33¼”

43 7/8”

30”

41¼”

S1850/S2200/S3200

1500 lbs.

4 (6*)

1/2” dia.

75¾”

36¾”

48 7/8”

37¼”

46¾”

*For optional filter section

** Dimensions allow for ¾” clearance on each side

Содержание S Series

Страница 93: ...S Series Technical Manual 91 Cambridge Air Solutions REFERENCE ELECTRICAL CONTROL ENCLOSURE ISOMETRIC DRAWING ...

Страница 100: ...Cambridge Air Solutions 98 S Series Technical Manual REFERENCE BUILDING AUTOMATION SYSTEM ...

Страница 112: ...Cambridge Air Solutions 110 S Series Technical Manual MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 113: ...MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 114: ...Cambridge Air Solutions 112 S Series Technical Manual ...

Страница 116: ...760 Long Road Crossing Dr Chesterfield MO 63005 Phone 636 532 2233 800 899 1989 Fax 636 530 6133 www cambridgeair com ...