Cambridge Air Solutions

60

S-Series Technical Manual

b. Insert key and turn the mode selector switch to the

“HEATING” position.

c. Set the operating thermostat, if applicable, to its

highest setting or activate that part of the control

system which will initiate blower and burner

operation

For Remote Control Station - Security (RCS-S),

refer to the Operating Instructions for the Operating

Electronic Thermostat (OET) (page 64).

For Temperature Setback System (TSS), refer to the

Operating and Programming Instructions for the

TSS Controller (page 66).

If another interlock device controls the operation of

the heater, activate this device.

d. After the motorized discharge damper opens, the

blower motor will start.

e. After a delay for prepurge and igniter warmup, the

burner will ignite.

f. Adjust the temperature control system and verify the

heater output changes correspondingly.

For EDSM, adjust the Space Temperature Selector.

For EDR, adjust the Remote Heat Adjust.

g. Reset the operating thermostat, if applicable, and

the temperature control system, if applicable, to the

desired temperature. If the Entering Air Thermostat

was adjusted, reset to its previous setting.

h. Turn the mode selector switch to the “SUMMER

VENTILATION” position. Verify the blower oper-

ates. In TSS applications, the override timer may

need to be activated to initiate operation.

i. Turn the mode selector switch to the desired

operating mode.

CALIBRATION PROCEDURES

EDL CONTROL SYSTEMS

(MAXITROL SERIES 14)

1. Turn the blower and burner service switches to the

“OFF” position.

2. Turn the heater disconnect switch to the “ON”

position.

3. Adjust the temperature setting on the amplifier dial

to 160°.

4. Turn the blower service switch to the “LOCAL”

position. The blower motor will start.

5. Turn the burner service switch to the “LOCAL”

position. After a delay for prepurge and igniter

warm-up, the burner will light. Allow 5 minutes for

the sampling box temperature to stabilize.

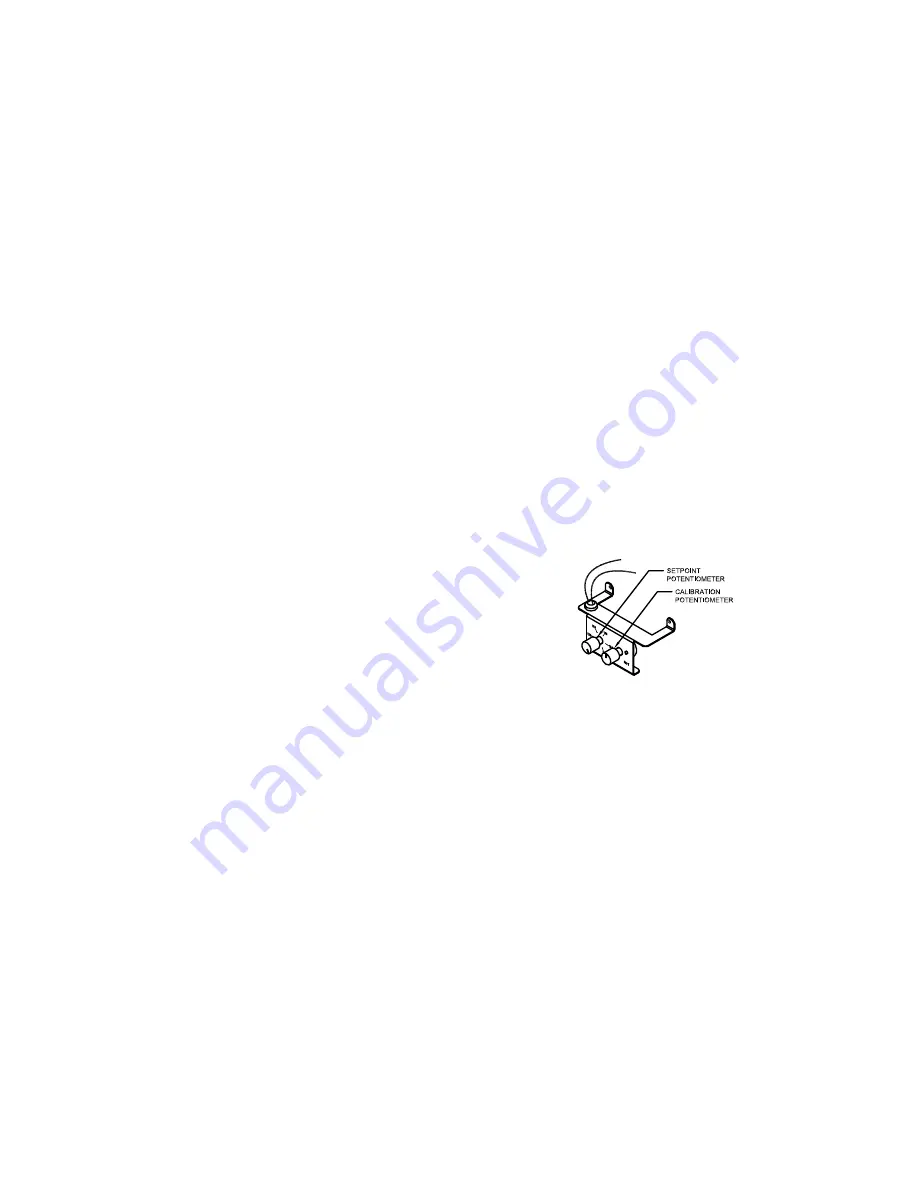

6. Adjust the calibration potentiometer as shown in

the drawing. To raise the discharge temperature

adjust the dial clockwise. To lower the discharge

temperature adjust the dial counterclockwise.

7. Wait for the discharge temperature and manifold

pressure to stabilize. Do not rush this step.

8. Repeat steps 6 and 7 until the mixing box

temperature has stabilized at 155°-160°.

9. Remove the thermocouple from the Sampling Box

port and replace the Sampling Box cover. Close the

heater access doors.

10. Verify that the discharge temperature and

manifold pressure comply with the guidelines of

the Calibration Check procedure step 8b. Repeat

steps 1 through 9 if necessary.

11. Turn the disconnect switch to the “OFF” position.

12. Turn the blower and burner service switches to the

“REMOTE” position.

Содержание S Series

Страница 93: ...S Series Technical Manual 91 Cambridge Air Solutions REFERENCE ELECTRICAL CONTROL ENCLOSURE ISOMETRIC DRAWING ...

Страница 100: ...Cambridge Air Solutions 98 S Series Technical Manual REFERENCE BUILDING AUTOMATION SYSTEM ...

Страница 112: ...Cambridge Air Solutions 110 S Series Technical Manual MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 113: ...MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 114: ...Cambridge Air Solutions 112 S Series Technical Manual ...

Страница 116: ...760 Long Road Crossing Dr Chesterfield MO 63005 Phone 636 532 2233 800 899 1989 Fax 636 530 6133 www cambridgeair com ...