S-Series Technical Manual

79

Cambridge Air Solutions

MAINTENANCE INSTRUCTIONS

m

WARNING:

Turn the disconnect switch off when performing

service or maintenance functions.

BLOWER BEARING LUBRICATION

Heaters with 3 HP or smaller motors have

permanently lubricated, double shielded and double

sealed ball bearings which do not require additional

lubrication. Heaters with 5 HP or larger motors

require lubrication on intervals of 3 to 6 months. Use

Duralube AW-2G, Goldplex (Lithplex HC 150 SMG),

Shell Gadus S2V100 2 or Mobilith AW2 grease.

Grease should be bearing quality and compatible to

lithium bases thickener.

MOTOR BEARING LUBRICATION

Motors are pregreased normally with Exxon Polyrex

EM. Equivalent greases which are compatible with

the Exxon Mobil lithium complex greases and electric

motor polyurea greases per ASTM D6185.

Annual Motor

Operation

Recommended

Lubrication Interval

NEMA 215T

Frame or

smaller

NEMA 254

Frame or

larger

Intermittent Operation -

>5000 hours

5 years

3 years

Continuous Operation -

Standard Service

2 years

1 year

Seasonal Service

(Motor is idle for 6

months or more)

1 year

Continuous Operation -

Severe Service

(High ambient, dirty

or moist location, high

vibration)

6 months

FILTERS

Filters may be provided in a V-bank filter section.

Filters may be of the disposable or permanent type.

Service the filters as needed based on the ”loading”

experienced. Clean filters typically start out with a

pressure drop across the filters between 0.15 and 0.25”

WC. Cleaning or replacement is generally required

below the pressure drop increased by a factor of 4

times the initial clean value.

Turn off the heater before servicing the filters.

Remove the filters from the filter section by opening

the filter access door. Handle the filters carefully to

prevent debris from being dislodged from the filter

into the heater.

Permanent Filters are 2” thick expanded aluminum

washable filters in aluminum frames.

Permanent filters can be cleaned using a stream of

water or soap and water. Back flush the filters until

the water comes out clean. If soap is used, ensure that

all soap is rinsed out of the filter. Visually inspect the

filter to ensure that it is clean. Allow to dry before

returning to service.

Disposable Filters are 2” thick cotton/polyester

panels with galvanized expanded metal pleat support

grids and beverage board frames.

Disposable filters are replaced when they become

dirty. Replace the filter with the same size of filter

which is removed from the filter section. Note the

airflow markings on the filter.

Model

Quantity

Size

S400/S800

2

20” x 25” x 2”

S950/S1200/S1600

4

20” x 25” x 2”

S1850/S2200/S3200

12

16” x 25” x 2”

Содержание S Series

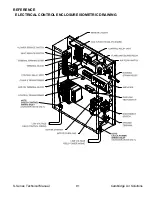

Страница 93: ...S Series Technical Manual 91 Cambridge Air Solutions REFERENCE ELECTRICAL CONTROL ENCLOSURE ISOMETRIC DRAWING ...

Страница 100: ...Cambridge Air Solutions 98 S Series Technical Manual REFERENCE BUILDING AUTOMATION SYSTEM ...

Страница 112: ...Cambridge Air Solutions 110 S Series Technical Manual MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 113: ...MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 114: ...Cambridge Air Solutions 112 S Series Technical Manual ...

Страница 116: ...760 Long Road Crossing Dr Chesterfield MO 63005 Phone 636 532 2233 800 899 1989 Fax 636 530 6133 www cambridgeair com ...