S-Series Technical Manual

89

Cambridge Air Solutions

1. Before reinstalling the damper motor into the heater

assembly, remove the black plastic weather cover

from the damper motor by removing the screw that

secures the cover to the damper assembly using

either a flat tip screw driver or a ¼” nut driver.

It may be necessary to twist the cover slightly to

disengage it from its mounting to the end of the

motor after the screw is removed.

2. Verify the damper motor is in the CLOSED

position (Drive tube is retracted with a minimum of

1/4” gap between the drive tube and the body of the

damper assembly).

3. Verify the inner cam has fully engaged the lower

limit switch plunger and the lower limit switch

(next to the body of the damper motor) shows

continuity between the common (C) terminal and

the normally open (NO) terminal.

m

CAUTION:

If the lower limit switch does not indicate

continuity, the damper motor must be driven to

the fully CLOSED position BEFORE connecting

the damper linkage tube to drive tube of damper

motor assembly.

IMPORTANT

If the drive tube bottoms out against the damper

motor housing, damage to the PC board or tripping

of the onboard fuse may result. If the fuse trips, place

the blower service switch in the OFF position for 15

seconds to allow fuse to reset. Proceed with steps 4

through 10 PRIOR to connecting the damper motor to

the linkage tube.

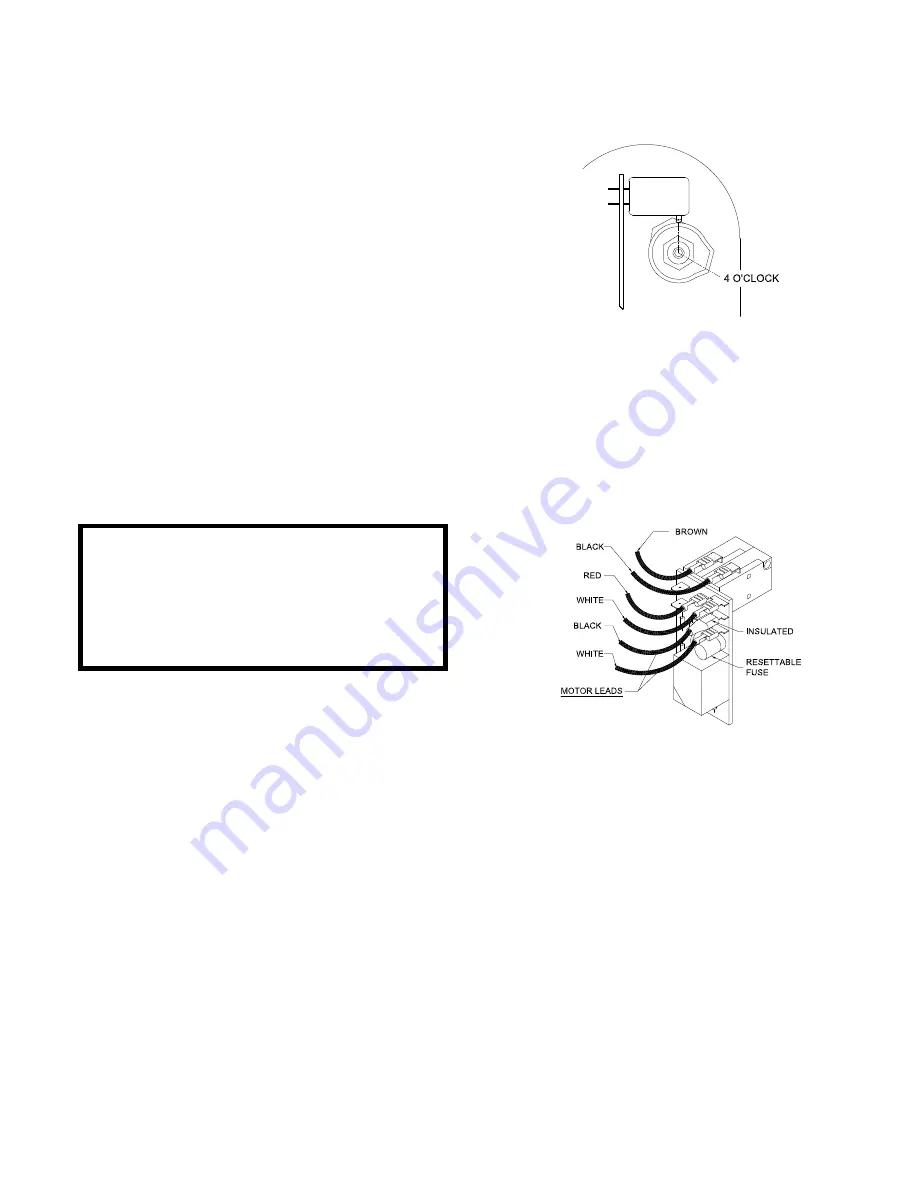

4. Verify the cam location on the upper cam is set just

short of the four o’clock position with respect to the

switch plunger being the twelve o’clock reference

position. If it is beyond the four o’clock position,

use a deep well 1/2” hex socket or nut driver and

manually rotate the cam counterclockwise a few

clicks, as required, to obtain the correct starting

position. (Refer to Figure 1.)

Figure 1

5. Verify the heater disconnect switch is turned OFF

and the service switches are in the OFF position.

6. Connect the wires to the terminals as shown in

Figure 2 and reinstall the cover.

Figure 2

7. Remove the push-in plug (located in the weather

cover) to have access to the upper cam adjusting

nut.

8. Connect the motor pivot to the damper motor

support bracket using the 3/8” diameter clevis pin.

IMPORTANT

Do not connect the damper linkage tube at this time.

9. Remove the wire from the ”G” terminal of the

terminal block. (This is to avoid a ”Call-for-Fan”

signal from the remote control station during the

next two steps).

TROUBLESHOOTING INSTRUCTIONS

DAMPER MOTOR REPLACEMENT & ADJUSTMENT

Содержание S Series

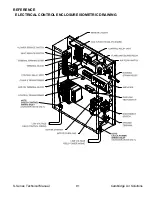

Страница 93: ...S Series Technical Manual 91 Cambridge Air Solutions REFERENCE ELECTRICAL CONTROL ENCLOSURE ISOMETRIC DRAWING ...

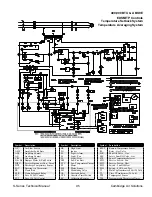

Страница 100: ...Cambridge Air Solutions 98 S Series Technical Manual REFERENCE BUILDING AUTOMATION SYSTEM ...

Страница 112: ...Cambridge Air Solutions 110 S Series Technical Manual MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 113: ...MAINTENANCE LOG MODEL NO SERIAL NO Date Activity Technician ...

Страница 114: ...Cambridge Air Solutions 112 S Series Technical Manual ...

Страница 116: ...760 Long Road Crossing Dr Chesterfield MO 63005 Phone 636 532 2233 800 899 1989 Fax 636 530 6133 www cambridgeair com ...