5 Operation

5.8.3 Torque Limiting Using an Analog Voltage Reference

5-58

(1) Input Signals

Use the following input signals to limit a torque by analog voltage reference.

Refer to

5.5.1 Basic Settings for Torque Control

.

(2) Related Parameters

Set the following parameters for torque limit by analog voltage reference.

Type

Signal Name

Connector

Pin Number

Name

Input

T-REF

CN1-9

Torque reference input

SG

CN1-10

Signal ground for torque reference input

Pn400

Torque Reference Input Gain

Classification

Setting Range

Setting Unit

Factory Setting

When Enabled

10 to 100

0.1 V

30

(Rated torque at 3.0 V)

Immediately

Setup

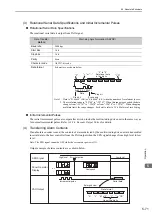

Pn402

Forward Torque Limit

Classification

Setting Range

Setting Unit

Factory Setting

When Enabled

0 to 800

1%

800

Immediately

Setup

Pn403

Reverse Torque Limit

Classification

Setting Range

Setting Unit

Factory Setting

When Enabled

0 to 800

1%

800

Immediately

Setup

Pn415

T-REF Filter Time Constant

Classification

Setting Range

Setting Unit

Factory Setting

When Enabled

0 to 65535

0.01 ms

0

Immediately

Setup

Speed

Position

Torque

Speed

Position

Torque

Speed

Position

Torque

Speed

Position

Torque