3 Wiring and Connection

3.10.1 Wiring for Noise Control

3-48

3.10

Noise Control and Measures for Harmonic Suppression

This section describes the wiring for noise control and the DC reactor for harmonic suppression.

3.10.1

Wiring for Noise Control

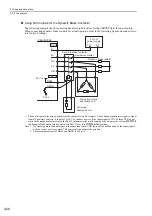

The multi-winding drive unit, SERVOPACKs, and converters use microprocessors. Therefore, noise influence

may be received from the multi-winding drive unit, SERVOPACK, and converter peripheral devices.

To suppress the influence of noise between peripheral devices and the multi-winding drive unit, SERVO-

PACKs, and converters, implement the following noise measures as required.

• Position the input reference device and noise filter as close to the multi-winding drive unit, SERVOPACK,

or converter as possible.

• Always install a surge absorber in the relay, solenoid and electromagnetic contactor coils.

• Do not bundle or run the main circuit cables together with the I/O signal cables or the encoder cables in the

same duct. Keep the main circuit cables separated from the I/O signal cables and the encoder cables with a

gap of at least 30 cm.

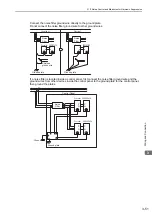

• Do not share the power supply with an electric welder or electrical discharge machine. If the SERVOPACK

is placed near equipment that generates high-frequency noise, install a noise filter on the input side of the

main circuit power supply cables and control power supply cables, even if the same power supply is not

used. As for the wiring of noise filter, refer to

(1) Noise Filter

shown below.

• Take the grounding measures correctly. As for the grounding, refer to

(2) Correct Grounding.

• Because the multi-winding drive unit, SERVOPACKs, and converters are designed as

industrial devices, they provide no mechanism to prevent noise interference.

• The SERVOPACKs and converters use high-speed switching elements in the main

circuit. Therefore peripheral devices may receive switching noise. If the equipment is

to be used near private houses or if radio interference is a problem, take countermea-

sures against noise.

• If installation conditions by the EMC directive must be met, refer to

2.4 EMC Installa-

tion Conditions in

Σ

-V

User’s Manual for Use with Large-Capacity Models Setup Rota-

tional Motor

(No.: SIEP S800000 85).