CL3/CL1

122

1. Preparation

1-1. Measuring instruments

Use measuring instruments which can measure the inspection

items accurately with con

fi

dence.

Input impedance of the measuring device should be 100 k

Ω

or

more.

• System Two

• Tester

• Filter (12.7 kHz, -6dB/OCT)

• Level meter

1-2. Parameters

◇

Unless otherwise specified, the parameter settings are as

follows.

• Set the WORD CLOCK to INT 48 kHz.

• Set the “+48 V MASTER” to ON.

• Turn on only the channel being measured.

PAN:

CENTER

GAIN: MIN

FADER:

NOMINAL (0 dB)

PHONES LEVEL:

MAX

TALKBACK GAIN:

MAX

• 0 dBu = 0.775 Vrms

• 0 dBFS = 0 dB, full scale

• The oscillator output impedance should be 150

Ω

• Correct the noise level measurement with a 12.7 kHz, -6

dB/octave low pass

fi

lter.

(For measurement, use the average values and not effective

values.)

• Correct the distortion measurement with an 80 kHz -18

dB/octave low pass

fi

lter.

◇

For analog output inspection, add or change parameter

settings as follows.

• For maximum output measurement, unless otherwise

speci

fi

ed, output 0 dB from the built-in oscillator.

• Set the analog output loads as follows.

OMNI OUT:

600

Ω

PHONES: 8

Ω

1-3. Updating the Program

If the main program is not the latest version, it is required to

update it to the latest version.

* For the latest version, download the latest program from the

YSUSS home page and save it in the USB memory device.

(1) How to check the version of the main program

Press the [SET UP] button on the LCD screen and the current

version will be shown in the “SETUP” page screen.

(2) How to update the program

For the program updating procedure, refer to the “UPDATING

FIRMWARE”. (See page 164.)

1-4. Initialization

For initialization, turn on the power while pressing

the

[STORE]

switch and execute “INITIALIZE ALL

MEMORIES”. (See page 166.)

1-5. Fader Calibration

For the procedure of calibrating faders, refer to “FADER

CALIBRAION”. (See page 170.)

1-6. Color Bar Calibration

For the procedure of calibrating the color bar, refer to “COLOR

BAR AND CH NAME LCD CALIBRATION”. (See page 172.)

1-7. CPU circuit board MRAM Backup Check

Check that “Memory Error! Current Memories were Initialized”

does not appear on the LCD screen when the power is turned

on.

2. ANALOG IN/OUT Characteristic Inspection

2-1. OMNI IN 1-8

→

OMNI OUT 1-8

Parameters: Input the analog signal from INPUT (XLR)

of CH1-8 and measure the signal output from

OUTPUT of CH1-8.

Assign OMNI IN CH 1-8 to OMNI OUT 1-8.

A. AIN MAIN

1

Gain

Input

Frequency

Input Level

Prescribed

Output Level

Permissible

Range

1 kHz

+10 dBu

+4 dBu

+4±2 dBu

2

Distortion

Input

Frequency

Output Level

Permissible

Range

1 kHz

+22 dBu

0.01 % or below

3

Noise level

Parameters: Short the CH IN to be measured with 150

Ω

.

Permissible Range

–80 dBu or below

4

Residual noise (OMNI OUT 1-8)

Parameters: Set OMNI IN CH1-8 to OFF.

Permissible Range

–88 dBu or below

5

CH 1-8 level difference

Con

fi

rm that the range of difference in the gain measured in

item (1) above is as follows.

Permissible Range

Within 1 dB

■

INSPECTIONS

Summary of Contents for CL3

Page 7: ...7 CL3 CL1 DIMENSIONS CL3 CL1 648 15 201 130 299 667 839 15 201 130 299 667 Unit mm...

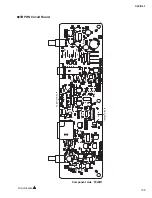

Page 95: ...95 CL3 CL1 CPU Circuit Board Pattern side to DSP CN101 2NA WY67750 1...

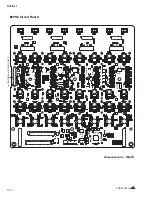

Page 101: ...101 CL3 CL1 DNTU Circuit Board Pattern side Scale 80 100 2NA WZ20390 5...

Page 102: ...CL3 CL1 102 2NA WY63530 FX Circuit Board WR 63 1 Component side Scale 95 100...

Page 103: ...103 CL3 CL1 2NA WY63530 FX Circuit Board Pattern side Scale 95 100...

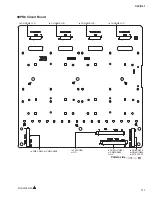

Page 105: ...105 CL3 CL1 HAAD Circuit Board Pattern side Scale 90 100 2NA WY64340 2...

Page 107: ...107 CL3 CL1 2NA WY63490 Component side JK Circuit Board WR 63 1...

Page 109: ...109 CL3 CL1 Component side TBPHN Circuit Board WR 06 1 WR 63 1 2NA WY64360 1...

Page 110: ...CL3 CL1 110 Component side PN8 Circuit Board to FD8 CN902 or FD8CN CN902 2NA WY53120 2...

Page 118: ...CL3 CL1 118 Component side PNENL Circuit Board to PN8 CN001 2NA WY53130 1...

Page 160: ...CL3 CL1 160 1 18 LCD Test LCD LCD 1 3 2 9 5 OK NG 1 2 H 3 O X O 4 BOX 5x4...

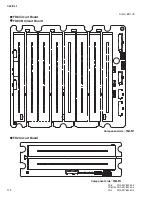

Page 382: ...7 MBCL CIRCUIT BOARDS A A A A 2NA WY53200 1 MB Circuit Board Component side...

Page 383: ...MBCL 8 MB Circuit Board DSUB PH CONNECTOR ASSEMBLY B B B B 2NA WY53200 1 Pattern side...