2 Instrument Configuration

Copyright © WOODLEY EQUIPMENT COMPANY LTD.

41

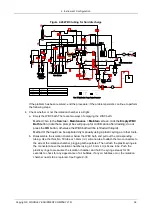

Figure 2-34 Tubing of the positive-pressure chamber

RBC

WBC

LV3

LV2

LV1

LV4

LV5

LV7

LV9

LV11

LV12

LV15

LV17

LV18

LV6

LV19

250ul 10ml

2.5ml

10ml

2.5ml

J13

T70

T29

T29

T29

J11

J12

T70

T70

T20 T134

T9

J6

J7

J6

J6

J6

J6

J6

T29

J6

J2

T29

T29

T29

T29

T29

J6

J6

T70

Check

valve

T72

T72

J5

J5

T72

J5

J2

T80

T80

T29

T29

T70

T80

T10

T10

T70

T48

T80

T48

T29

J3

J4

T11

T11

T14

J9

P1

T70

T67

T67

T70

One-way

valve

Air Filter

DIFF I

LH

DILU

LH

T237

T115

T70

T13

T70

DIFF I

T214

T15

T14

J1

T70

J3

P2

T80

T29

T70

J3

T80

T80

T80

T80

J3

T70

T171

J4

T29

T69

T28

T211

J3

T80

T80

T168

T29

T164

T197

T165

T80

T29

J3

T29

T29

J8

T105

LV16

LV8

J8

J2

J2

T5

T65

T58

T65

T52

T52

T51

T204

T169

T33

T42

T158

T238

T40

T80

T21

T156

T240

T242

T65

T236

T150

T152

T162

T66

T83

T197

T59

T214

T221

T210

T210

T70

T70

T70

T70

T72

T72

T72

T171

T168

T177

T197

T186

T195

T72

T72

T80

T80

T80

T80

T176

T70

250ul

T80

J3

T80

J3

LV14

LV13

LV10

LV20

LV21

T29

T19

T29

T29

T29

J3

T80

T195

J10

T80

T80

T65

J2

J2

T197

J10

T73

T39

T82

T87

T67

T67

T80

T89

J10

T171

T38

T239

T171

T170

T177

T199

J10

J10

T170

T57

T105

T241

J6

J2

T70

J10

T80

J6

2

3 1

2:COM

1:NC

3:NO

Three-way valve

Tow-way valve

2

1

Note

:

LV-liquid value

;

P-pump

;

T-pipe

;

J-connector

Name

Quantity

Note

Valve

Pump

Syring

21

6

2

2:IN

1:OUT

J3

T43

T26

T65

SE Sampling

Syringe

Lyse Syringe

Negative-

pressure

Sensor

Dual Pipe

Positive-pressure Sensor

V5 LY1 V5 LY2

V5 DIL

3. Check if the pump is working; if not, replace the pump.

4. Check if the positive-pressure sensor and the corresponding electrical circuit are in normal

working order. First replace a reagent testing panel and reconnect its tubing, then check if the

positive pressure is normal in the status interface; if it is normal after the replacement, this means

that the positive-pressure sensor and the corresponding electrical circuit are causing a problem

with building positive pressure (After the reagent testing panel is replaced, note that the tubing

needs to be connected correctly. First keep a record of where it was by marking it before

disassembling the tubing).

5. Check the valve directly connected to the tubing of the positive-pressure chamber to see 1)

whether the on-off switch is normal; and 2) whether there is any clogging.

6. After troubleshooting, complete the steps shown in the

Remove Error

wizard.

2.2.12.10 Problems in Creating the Negative Pressure

The troubleshooting steps are as follows:

1. Check if the negative-pressure chamber is broken: Disassemble the negative-pressure chamber

if necessary and seal the openings with rubber tubes. Then put the negative-pressure chamber

into the water tank. Use a syringe or other equipment to pressurise the negative-pressure

chamber. Any air bubbles that occur indicate that the negative-pressure chamber needs to be

replaced.

2. Check if there are any kinks or damage along the tubing connected to the negative-pressure

chamber. Any replacements should be made using tubing of the proper length and type.