GENERAL AIR PRODUCTS, INC.

For Assistance Please Call 1-800 345-8207

Please keep these instructions for future reference.

OILLESSINST

REV 080906

OIL-LESS COMPRESSOR INSTRUCTION SHEETS

NOTE

This compressor is intended for installation indoors for use on dry sprinkler systems in accordance with the

Standard for Installation of Sprinkler Systems, NFPA 13 and the National Electrical Code, NFPA 70.

The compressor should be sized to restore and maintain the air pressure in the sprinkler system in

accordance with the requirements in NFPA 13.

DANGER

This compressor is not equipped and should NOT be used “as is” to supply breathing quality air.

WARNING

Motors, electrical equipment and controls can cause electrical arcs that will ignite a flammable gas or vapor.

Never operate or repair in or near a flammable gas or vapor. Never store flammable liquids or gases near

the compressor.

WARNING

These compressors are suitable for pumping only atmospheric air. As defined in Compressed Gas

Association Pamphlet G-7, page 3, atmospheric air is a mixture of elements and compounds where nitrogen

and oxygen comprise more than 99% with all other trace gases comprising less than 1%.

DO NOT USE

THIS COMPRESSOR IN CONTAMINATED ENVIRONMENTS OR FOR PUMPING MIXTURES OTHER

THAN ATMOSPHERIC AIR

WARNING

Compressed air contains liquid water and is saturated with water vapor, which can freeze. Do not connect

compressor outlet to freezer rooms or systems exposed to temperatures below freezing. If system connects

to a freezer room or area exposed to freezing temperatures, a Dry Air Pac™ should be used.

Receiving

Your compressor is inspected at the factory and

packaged to protect against shipping damage. When

the compressor is unpacked, inspect for damage or

missing parts. All claims should be settled directly

with the freight company.

WARNING:

Do not operate this compressor

if damaged during shipment, handling, or use.

Damage may result in bursting and cause

injury or property damage.

Location

NOTE

:

Do not connect compressor intake to

freezer room. – CALL 1-800-345-8207.

Locate the compressor in a clean, well-ventilated area

where the air is relatively cool, clean, and dry. A

110

o

F (35 C) maximum and 40

o

F (4.5 C) minimum

temperature for surrounding and inlet air are

recommended. Provide at least 12 to 18 inches from

any wall or other obstruction that will interfere with

airflow through the motor’s fan built into the motor.

Blocking airflow through the fan may cause the

compressor to over heat. Do not place the compressor

in an area of excessive heat, such as near a boiler.

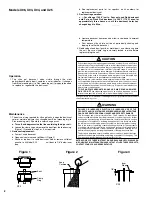

Mounting

Riser mounted compressors may be mounted to a firm

level floor, wall or system riser. A mounting bracket

and straps are provided. Tank mounted compressors

should be bolted to the floor using the bolt holes

provided in the tank legs. Always shim the unit level

before bolting it to the floor. Vibration isolators (P/N

KVP4X4) are recommended. When using isolator

pads, do not draw bolts tight. Allow the pad to absorb

vibrations. When isolators are used, a flexible hose

(P/N P1202MP) should be installed between the

compressor and service piping.

Lubrication

NOTE

:

This compressor is designed for

non-lubricated service. Bearings are

permanently lubricated. Do not lubricate any part

of the compressor or motor.

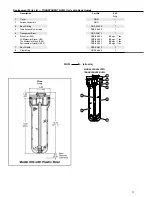

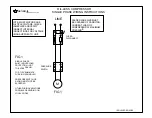

Piping (reference “Installation

Instructions” drawings)

WARNING

Compressed air contains liquid water and is

saturated with water vapor, which can freeze. Do

not connect compressor outlet to freezer rooms

or systems exposed to temperatures below

freezing. If system connects to a freezer room or

area exposed to freezing temperatures, a Dry Air

Pac™ should be used.

Piping between the compressor, accessory items and

the sprinkler system should be at least ½” internal

APPENDIX E