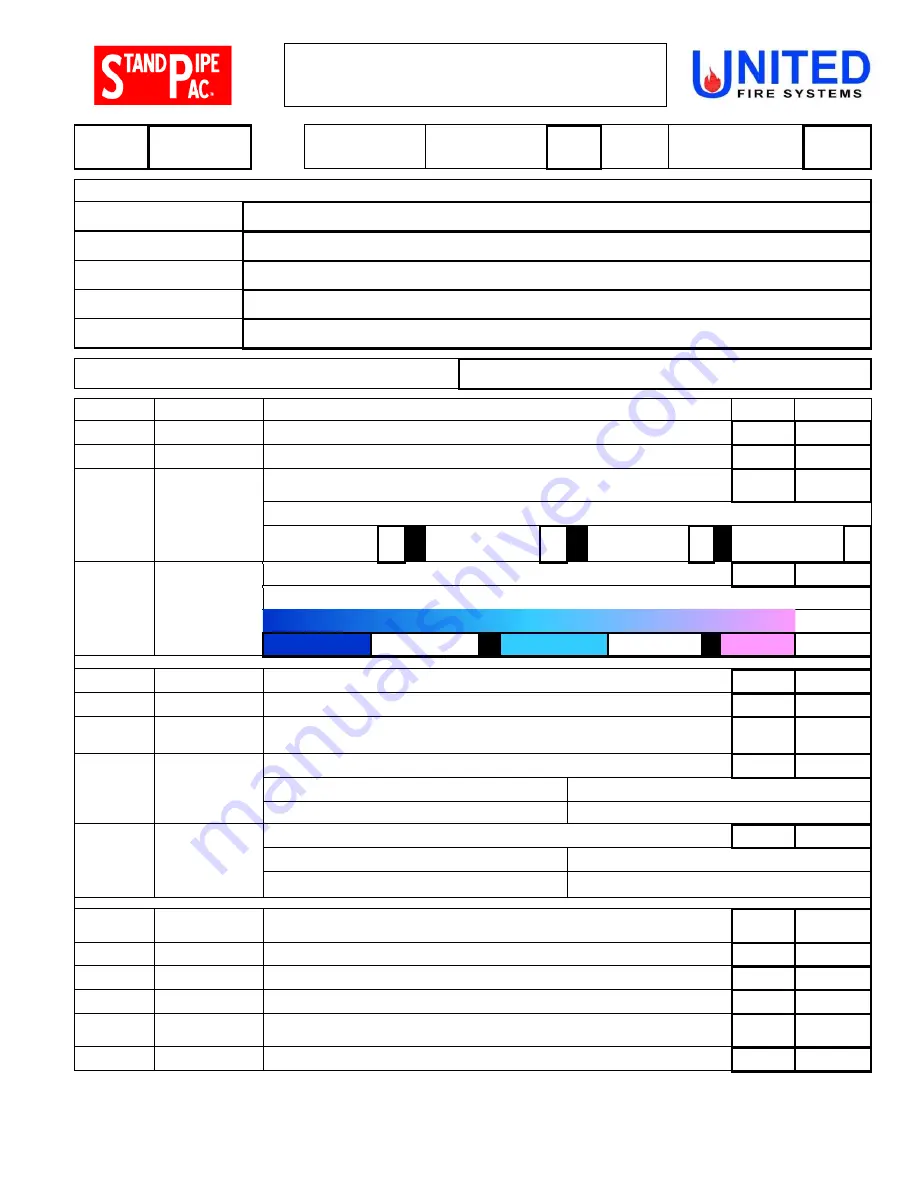

Page 41

DATE

Is this (check

one):

Monthly

Inspection

=or=

Quarterly

Maintenance

LOCATION INFORMATION

User

Address 1

Address 2

City, State, Zip

System

STANDPIPE-PAC UNIT SERIAL NUMBER

STEP

INTERVAL

PROCEDURE

OK

NOT OK

1

Monthly

Is the unit installed in an area protected from outdoor elements?

2

Monthly

Is the unit installed in a heated area, and is the temperature over +32

°

F?

3

Monthly

Has the area where the unit is installed been checked for relative

cleanliness?

Choose the phrase BEST describing the area where the unit is installed.

Relatively

clean

Somewhat

dusty / dirty

Very

dusty / dirty

Extremely

dusty / dirty

4

Monthly

Has the color of the desiccant in the air dryer been checked?

Indicate below which color is the makes up the MAJORITY of the desiccant:

DARK BLUE

LIGHT BLUE

PINK

5

Quarterly

Has the air dryer desiccant been replaced with new desiccant?

6

Quarterly

Has the compressor inlet filter been replaced with a new filter?

7

Monthly

Has the Auxiliary Condensate Drain Device been properly used to remove

water from the piping in the vicinity of the STANDPIPE-PAC

™ ?

8

Quarterly

Has the HIGH PRESSURE signal been checked?

1. Lockable shutoff valve CLOSED.

2. Compressor disconnect switch ON.

3. Operate test / service device.

Signal horn should sound at 23±1 PSIG

9

Quarterly

Has the LOW PRESSURE signal been checked?

1. Lockable shutoff valve CLOSED.

2. Compressor disconnect switch OFF.

3. Operate test service device.

Signal horn should sound at 7 ± 1 PSIG.

10

Monthly

Has the unit been left with the

GREEN

visual indicator for AC POWER

ON

and all other visual indicators

OFF

?

11

Monthly

Has the compressor disconnect switch been left

ON

?

12

Monthly

Is the pressure gage indicating between 13 and 18 PSIG?

13

Monthly

Has the lockable outlet shutoff valve been left

OPEN

and locked?

14

Monthly

Is the manual release bleed valve at each fire department connection

CLOSED

with cap and chain connected and tight?

15

Monthly

Are all standpipe valves

CLOSED

?

INSPECTION / MAINTENANCE CHECKLIST

STANDPIPE-PAC

™ SUPERVISORY SYSTEM

UFS-236 REVISION 2.00

– PAGE 1 OF 2