UNITED FIRE SYSTEMS

STANDPIPE-

PAC™ MODEL SSS-101

DESIGN, INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

REVISION 2.00

P/N 10-540101-001

Page 13

3.3.5. Electrical Installation.

3.3.5.1. Codes.

All

STANDPIPE-

PAC™

wiring and wiring methods shall be in strict compliance with NEC and local

codes.

3.3.5.2.

Personnel.

All wiring shall be performed by licensed electricians.

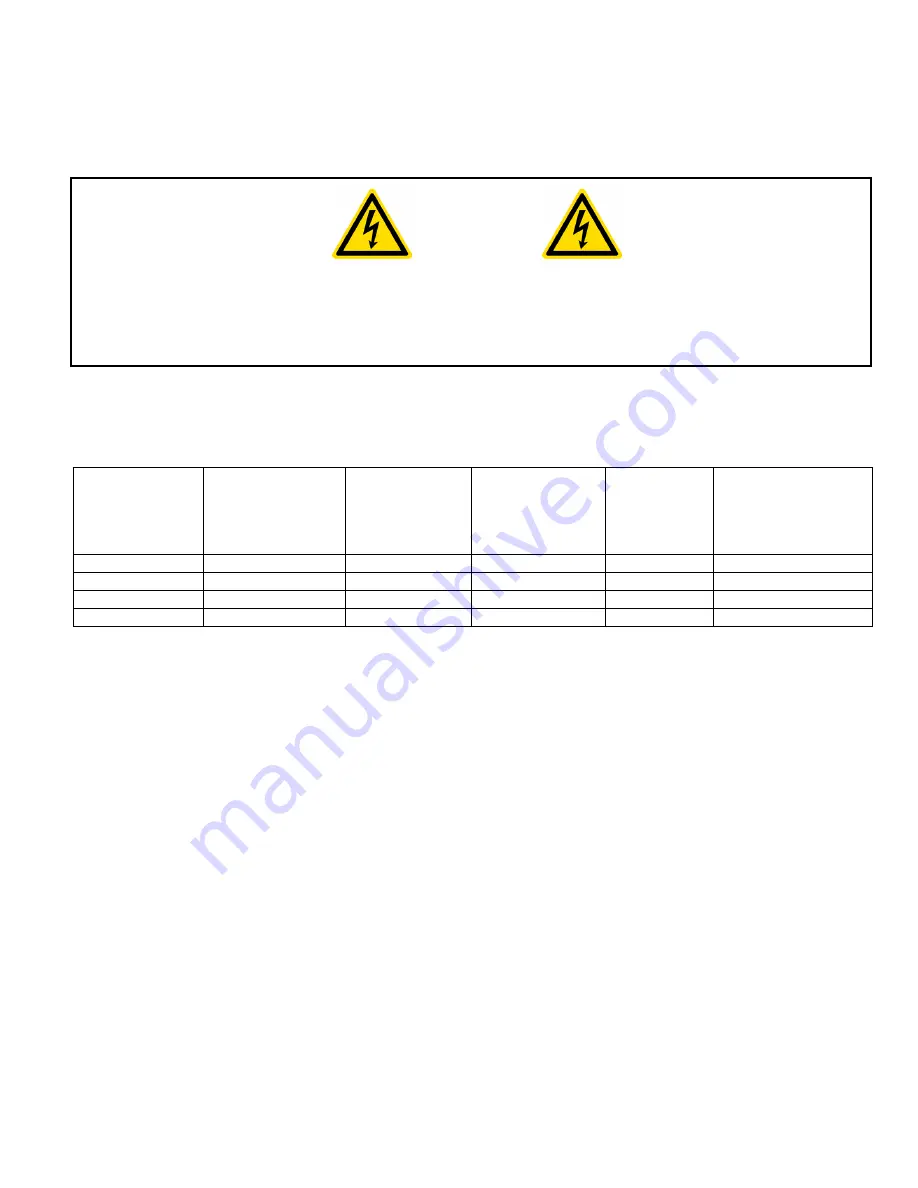

Part No.

Compressor Motor

And Control Unit

Voltage (V) /

Phase

Frequency (Hz)

Compressor

Motor

Horsepower

(HP)

Compressor

Motor

Current

(A)

Control

Unit

Current

(A)

STANDPIPE-

PAC™

Total

Current

(A)

SSS-101-16

115 / 1 / 60

1/6

6.6

0.7

7.3

SSS-101-13

115 / 1 / 60

1/3

6.6

0.7

7.3

SSS-101-12

115 / 1 / 60

1/2

8.0

0.7

8.7

SSS-101-34

115 / 1 / 60

3/4

10.6

0.7

11.3

3.3.5.3. Power Wiring.

See Table 3. Choose minimum conductor sizes and overcurrent protective device based on

total current shown in table. Connect power in junction box provided for the purpose

– see Figure 1. When

connecting power, ensure circuit breaker is OFF. Do not turn on circuit breaker until installation is complete and

system is ready for commissioning.

DANGER

RISK OF ELECTROCUTION

Voltages and currents associated with

STANDPIPE-

PAC™

units are

LETHAL

. Follow all instructions provided.

Work on

STANDPIPE-

PAC™

unit power MUST be performed ONLY by qualified individuals. All required

precautions to prevent contact with live electrical conductors and equipment MUST be taken. Failure to comply with

these instructions is an immediate hazard with a likelihood of death or serious personal injury!

Table 3

– Current Requirements –

STANDPIPE-

PAC™

Units