GENERAL AIR PRODUCTS, INC.

For Assistance Please Call 1-800 345-8207

Please keep these instructions for future reference.

OILLESSINST

REV 080906

diameter to minimize pressure drop from the

compressor to system. Larger pipe size may be

required by code and may be substituted with no

adverse effects. Smaller line size must not be used

and will restrict the compressor flow, lowering

capacity and causing the compressor/motor to work

harder, which shortens compressor/motor life. All

piping connected to the compressor must be fully

supported and not transfer any loads to the

compressor.

If an AMD-1 is used, allow sufficient distance

between the compressor and AMD-1 to ensure that the

maximum temperature at the AMD-1 is 200

o

F or less.

When an AMD is used with riser mounted units, a

riser mounted tank kit (p/n OLR-TK) should be

installed to prevent short cycling the compressor.

All oil-less compressors include a relief valve. For

riser mounted models, the relief valve is installed on

the compressor outlet. For tank mounted models, an

ASME Code relief valve is mounted on the

compressor’s tank. This valve will open at a preset

value above the pressure switch setting to prevent

excess tank pressure in the event of switch failure.

WARNING:

Do not attempt to change the

safety relief valve setting

.

A manual drain is provided on the bottom of each tank

mounted compressor. Moisture accumulated in the

tank, must be drained weekly. An automatic drain ,

P/N DVA -2T, is recommended in areas of high

humidity.

The compressor outlet piping should contain an

accessible drain. As a minimum a manual drain may

be used, but an automatic drain is recommended to

remove excess water.

NOTE:

Accumulation of condensed water in a

system causes corrosion of components and

reduces system capacity.

NOTICE:

Warranty is void if a separate check

valve is not installed to prevent water back flow.

Wiring (reference “Wiring Instructions”

drawings)

WARNING

Have a qualified electrician wire the compressor

to ensure that the supply line has the same

characteristics (voltage, frequency and phasing)

as the motor. Wiring must comply with all local

and national codes.

CAUTION

Inadequate wiring size can cause insufficient

voltage at the compressor during start -up.

Overheating and damage to the motor and

controls may result

The supply wire must be of adequate size and no other

equipment should be connected to the same line. The

table below lists the recommended wire size for each

model, based on a 100’ run. Consult factory for

longer runs.

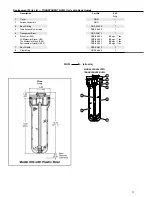

MINIMUM RECOMMENDED WIRE SIZE

MODEL

1 PHASE

3 PHASE

OL11016**

12

N/A

OL21533**

10

N/A

OL33550**

8

12

OL42575**

8

12

OL435V75**

8

12

OL525100**

8

12

OL610V100**

8

12

OL675150**

6

12

OL900V100**

8

12

OL900V150**

8

12

OL1200V200**

10

10

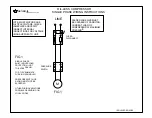

The motors supplied are multiple voltage motors. A

label on the pressure switch cover indicates the voltage

the motor is pre-wired for. If the supply voltage, on

site, is different from the voltage indicated on this

label, change the internal motor voltage connections to

match the supply voltage. To change internal voltage

connections, remove the cover plate located on the

rear or side of the motor and reconnect the wire leads

as shown on the motor’s wiring diagram.

On all three phase and ½ Hp and ¾ Hp single phase

models, an arrow on the motor indicates the direction

of rotation of the compressor. If the compressor

rotates in the opposite direction, reverse the rotation of

the motor. On single phase units, reverse motor

rotation by interchanging the red and black motor

leads. Interchanging any two incoming supply wires

reverses rotation of three phase motors.

NOTICE:

Single-phase oil-less

compressors can not be operated at 208V.

Operating the compressor at 208V voids the

warranty.

NOTICE

:

Single-phase motors include

internal thermal overload protection, which has

an automatic reset device.

WARNING:

Disconnect electrical power

before servicing to disable reset devices.

Thermal protection can automatically start the

motor when the protector resets.

On single phase models, the motor is pre-wired to the

pressure switch provided, which controls starting (cut