UNITED FIRE SYSTEMS

STANDPIPE-

PAC™ MODEL SSS-101

DESIGN, INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

REVISION 2.00

P/N 10-540000-001

Page 38

*

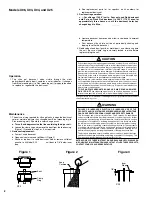

To drain water from piping in vicinity of

STANDPIPE-

PAC™

while standpipe is pressurized with air by

STANDPIPE-

PAC™:

1. Unlock and close

STANDPIPE-

PAC™

outlet valve.

2. Remove and retain steel plug from device outlet (Valve 2)

3. Open Valve 1 of Auxiliary Condensate Drain Device, allowing water to drain into device.

4. Close Valve 1 BEFORE opening Valve 2.

5. Open Valve 2 of Auxiliary Condensate Drain Device, allowing water to drain from device.

6. Close Valve 2 and re-open Valve 1. Repeat until no additional water drains from device outlet.

7. Replace steel plug in device outlet (Valve 2)

5.3. Quarterly.

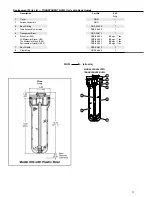

5.3.1 Replacement of Desiccant In Dryer.

It is important that the air dryer continue to remove moisture

from the compressed air. For this reason, it is recommended that the dryer desiccant be replaced

quarterly.

NOTE

– Refer to Figure 15.

1. Have Qty. (1) UFS P/N 21-100000-100 Replacement Desiccant available.

2. Notify local personnel that signals will be heard / seen during maintenance.

3. If dialer is connected to telephone line, notify receiving office that signals will be transmitted

during maintenance.

4. Close lockable shutoff valve on outlet of

STANDPIPE-

PAC™

.

5. Move compressor disconnect switch to OFF.

6. De-pressurize

STANDPIPE-

PAC™

piping by operating Test / Service Device. Hold until

pressure gauge indicates ZERO.

7. Silence audible signal by opening door of control unit and operating Acknowledge-Silence

button. Hold for 2 seconds until audible signal silences.

IMPORTANT

Quarterly maintenance as indicated below is vitally important for continued proper functioning of

your

STANDPIPE-

PAC™

. Please do NOT neglect these procedures!

CAUTION

DO NOT turn connecting ring on desiccant air dryer unless pressure gauge indicates ZERO.

Failure to do so can result in personal injury and property damage

.