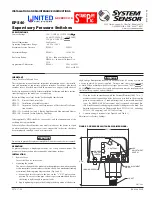

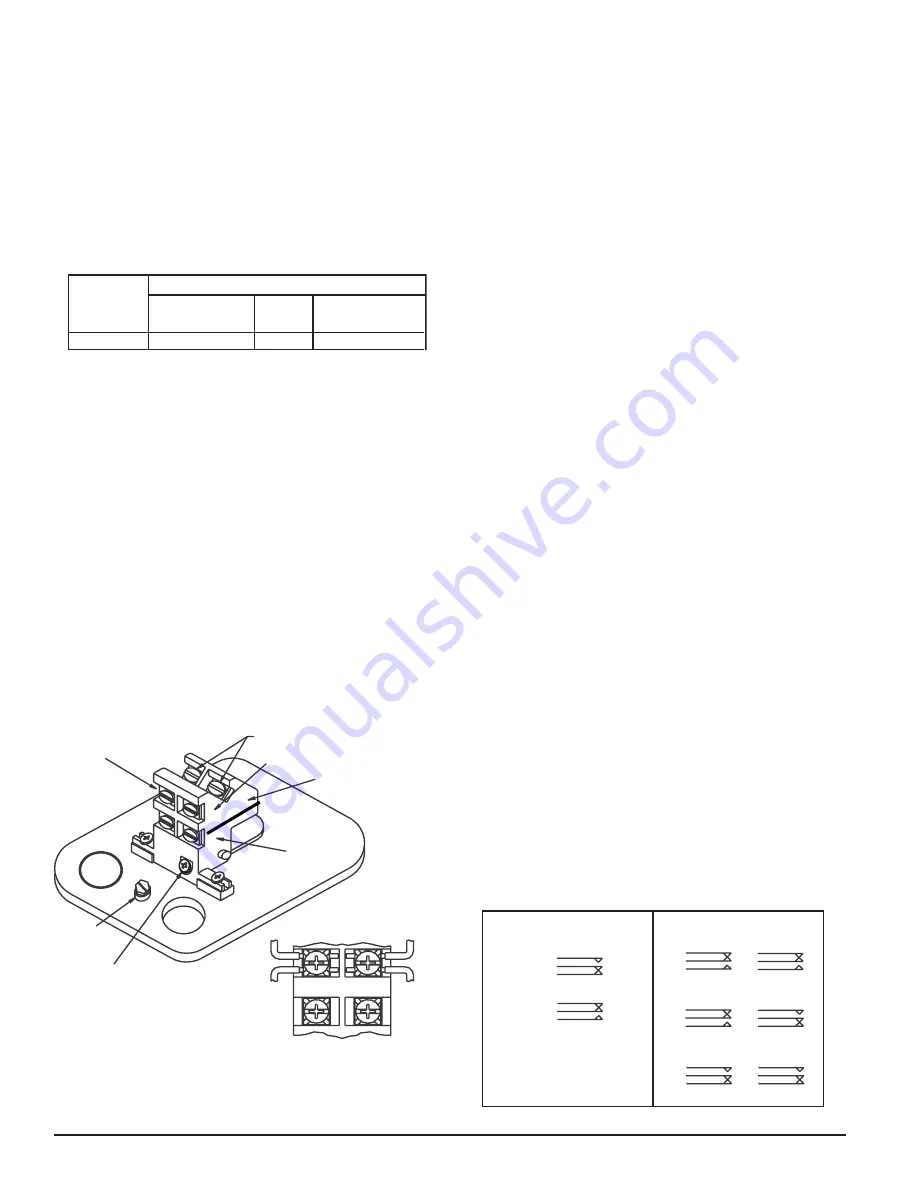

GROUND

SCREW

CO

M

B

A

COMMON

TERMINALS

BREAK WIRE AS SHOWN FOR

SUPERVISION OF CONNECTION.

DO NOT ALLOW STRIPPED WIRE

LEADS TO EXTEND BEYOND

SWITCH HOUSING. DO NOT

LOOP WIRES.

SWITCH #1

SWITCH #2

SW

ITC

H #

2

LOCKING

SCREW

TERMINAL “A”

TERMINAL “B”

D770-17-00

2 I56-0986-008R

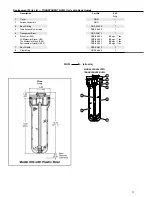

TABLE 2.

FACTORY SETTINGS (PSI)

MODEL

Fall SW2

(Low Switch)

Rise SW1

(Hi Switch)

Nominal

EPS40-1

EPS40-2

EPS120-1

EPS120-2

30

±

1.5

30

±

1.5

––

115

101.5 - 112.5

101.5 - 112.5

117.5 - 128.5

115

––

40

50

±

2.5

40

SINGLE-SWITCH MODEL — EPS40-1 AND EPS120-1

1. Install pressure switch as stated in “INSTALLATION” portion of instruc-

tion manual. Attach pressure test source to system.

2. Back off locking screw (see Fig. 4) to allow main adjustment wheel to

rotate freely.

3. Test the switch for the set point by introducing 40 PSI pressure from the

pressure test source for the EPS40-1 (115 PSI for the EPS120-1). Decrease

pressure slowly until the switch trips. Rotate main adjustment wheel,

Figure 5, (counterclockwise to increase pressure) and retest by first intro-

ducing a higher pressure than desired and slowly reducing pressure until

the switch trips. Repeat process until switch trip point is at desired pres-

sure setting. Each number represents an approximate trip point change

of 1.8 PSI for the EPS40-1 and 6.6 PSI for the EPS120-1. For each

1

/

2

rotation of the adjustment wheel, the trip point setting changes by ap-

proximately 11 PSI for the EPS40-1 and 40 PSI for the EPS120-1.

4. Retest the set point several times to ensure accuracy of setting.

5. Re-seat locking screw.

C0141-01

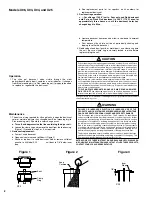

FIGURE 3. TYPICAL PIPING DIAGRAM FOR EPS120-1, EPS120-2

FIGURE 2. TYPICAL PIPING DIAGRAM FOR EPS40-1, EPS40-2

DRY

PIPE

VALVE

OS & Y

VALVE

WATER

BY-PASS

TEST

VALVE

LOCAL ALARM

SHUT OFF

VALVE

WATER

MOTOR

GONG

CHECK

VALVE

EPS40

CHECK

VALVE

AIR LINE

SHUT-OFF

VALVE

INSTALL

BLEEDER

VALVE FOR

TESTING

EPS10

DRY SYSTEM

WIRE TO SUPERVISORY

CIRCUIT OF FIRE ALARM

CONTROL PANEL

WIRE TO ALARM

INDICATING CIRCUIT

OF FIRE ALARM

CONTROL PANEL

TO

SPRINKLER

SYSTEM

FIGURE 4. SWITCH LOCATION:

W0185-01

W0186-00

TABLE 1. ELECTRICAL CONNECTIONS (REFERENCED AT FACTORY

SETTINGS):

MODELS EPS40-1, EPS120-1

SWITCH AT NORMAL SYSTEM PRESSURE

SWITCH AT TRIP POINT

B

COM

A

A

COM

B

SWITCH 1

SW2

SW1

SWITCHES AT NORMAL SYSTEM PRESSURE

SWITCHES AT LOW TRIP POINT

SW1

SW2

MODELS EPS40-2, EPS120-2

SWITCHES AT HIGH TRIP POINT

SW1

SW2

B

COM

A

B

COM

A

B

COM

A

A

COM

B

A

COM

B

A

COM

B

DUAL-SWITCH MODEL — EPS40-2 AND EPS120-2

1. Install pressure switch as stated in “INSTALLATION” portion of instruc-

tion manual. Attach pressure test source to system.

2. Back out the locking screw (see Fig. 4) to allow main adjustment wheel

to turn freely.

3.

Option 1: Adjust nominal pressure setting without affecting PSI window.

a) Adjust main adjustment wheel (see Fig. 5) to desired setting using

pressure source (i.e., valve or air maintenance device).

b) Turn main adjustment wheel counterclockwise to increase (see arrow

on mounting base) or clockwise to decrease pressure. Each number

on main adjust wheel represents an approximate window shift of 1.8

psi for EPS40-2 and 6.6 psi for EPS120-2. For each

1

/

2

rotation of the

adjustment wheel the window changes by approximately 11 psi for

EPS40-2 and 40 psi for EPS120-2.

c) Retest the set point several times to ensure the accuracy of the setting.

Option 2: Adjust pressure window size and nominal setting of pres-

sure window.

a) Adjust main adjustment wheel (see Fig. 5) until high switch (SW1)

trips at desired pressure using pressure test source (valve or air main-

tenance device).

b) Refer to step B from Option 1.

c) Decrease pressure until the low switch trips (SW2).

d) Adjust

1

/

4

˝ low pressure hex head nut (see Fig. 5) to either increase

(counterclockwise) or decrease (clockwise) the window size (the low

switch will be affected).

e) The approximate sensitivity of the hex screw adjustment:

1

/

2

turn

=5

psi. A maximum of 30 psi is attainable.

4. Retest the set points several times to ensure the accuracy of the settings,

and adjust as necessary.

5. Re-seat locking screw.

NOTE: EPS40 models are able to be set to a range within 8-100psi only when

used with Victaulic series 768 and 769 FireLock NXT valves pre-set for use

with low pressure actuators. When used on Victaulic series 768 and 769

FireLock NXT all units must be 100% tested to verify pressure setting. Both

the main adjustment wheel and low pressure adjusting screw (See Figure 5)

need to be customer set and tested to insure proper functionality. For pres-

sure setting instructions refer to Installation section for dual switch models in

this manual.

WET

SYSTEM

ALARM

CHECK

VALVE

OS & Y

VALVE

OS & Y

VALVE

WATER

BY-PASS

VALVE

AIR

PRESSURE

SUPPLY

BLEEDER

TEST

VALVE

EPS120

LOCAL ALARM

SHUT OFF

VALVE

RETARD

WATER

MOTOR

GONG

C0142-01