UNITED FIRE SYSTEMS

STANDPIPE-

PAC™ MODEL SSS-101

DESIGN, INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

REVISION 2.00

P/N 10-540000-001

Page 39

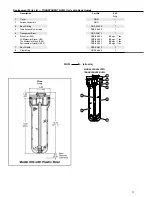

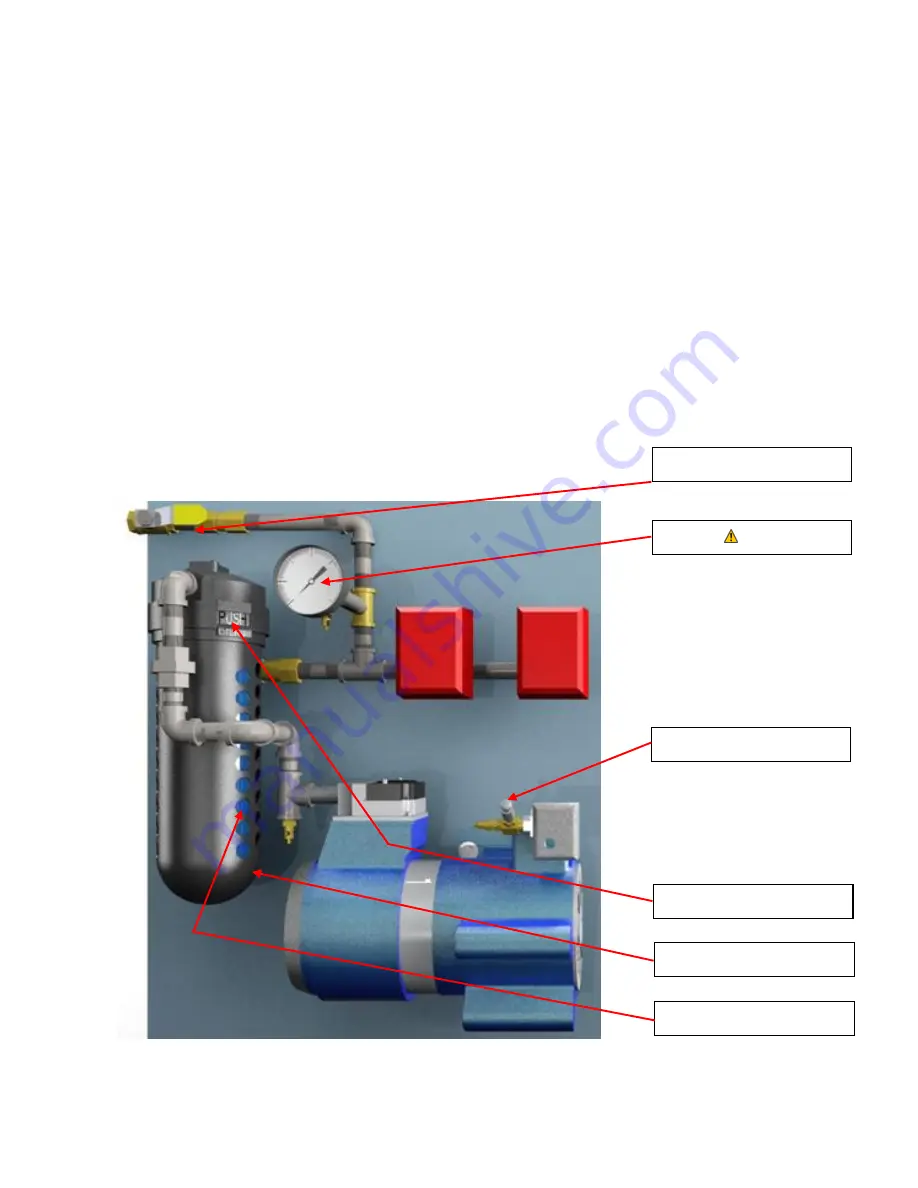

8. Locate desiccant air dryer on

STANDPIPE-

PAC™

. Locate tab marked PUSH on connecting

ring holding aluminum bowl in place (tab orientation may not be immediately visible).

9. Depress tab marked PUSH and turn connecting ring to release aluminum bowl and glass liner.

10. Detach aluminum bowl from assembly.

11. Remove and discard the desiccant beads in the bowl.

12. Fill glass liner with new desiccant beads to approximately the same level. Use Qty. (1) UFS

P/N 21-100000-100.

13. Carefully align and insert desiccant bowl back into assembly until it is flush against air dryer

cap.

14. Depress tab marked PUSH, and turn connecting ring until connection is re-established.

15. Release tab and ensure that aluminum bowl is secure.

16. Move compressor disconnect switch to ON. Compressor should start and pressure gauge

should begin to indicate.

17. When pressure gauge reads approximately 18 PSIG, compressor should stop.

18. Check for leaks at air dryer connecting ring.

19. Open lockable shutoff valve on outlet of

STANDPIPE-

PAC™

.

20. Notify local personnel (and receiving office, if phone line is connected) that maintenance is

complete.

See Step 4

See Step 6

See

CAUTION

See Step 8

See Step 10

See Step 12

Figure 15

– Desiccant Air Dryer