UNITED FIRE SYSTEMS

STANDPIPE-

PAC™ MODEL SSS-101

DESIGN, INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

REVISION 2.00

P/N 10-540000-001

Page 37

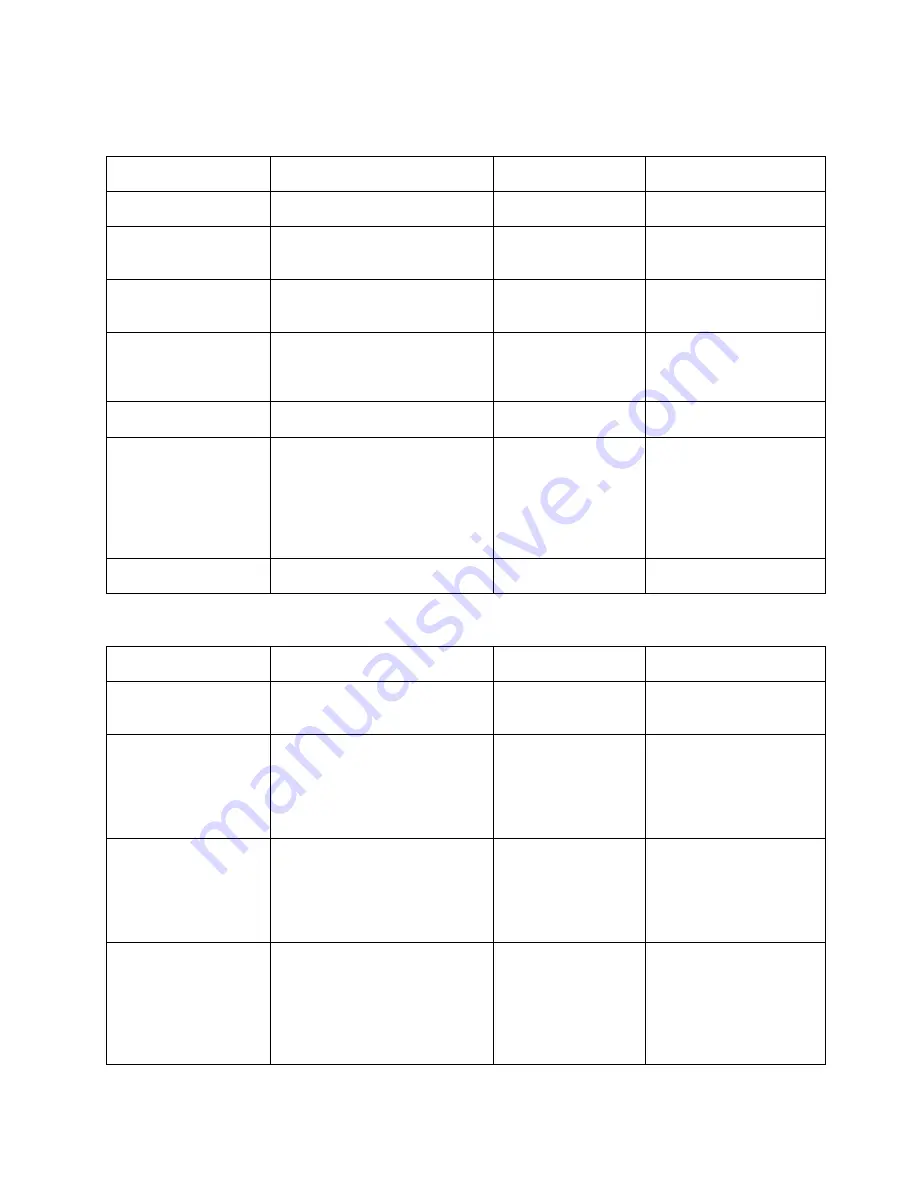

5.1. Weekly.

Weekly maintenance consists of visual checks of the status of the

STANDPIPE-

PAC™

unit and the standpipe itself.

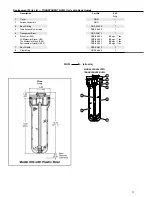

Item

Normal Status

Abnormal Status

What To Do If Status Is

Abnormal

Check control panel

visual indicators

AC Power Green LED

– ON

All other LED indicators - OFF

Any indicators other

than AC Power ON

Contact your service

provider for service.

Check Compressor

Disconnect Switch

ON

OFF

Return Compressor

Disconnect Switch to

ON position.

Check Pressure

Gauge

Indicating between 13 to 18

PSIG

Indicating below 13

PSIG or above 18

PSIG

Contact your service

provider for service.

Check Desiccant in

Air Dryer

Blue color

Orange color

If desiccant is orange

throughout, contact your

service provider for

service

Check Lockable

Shutoff valve

Locked in OPEN position

Unlocked or

CLOSED

Open valve and apply

lock.

Check Manual Air

Release Bleed Valve

Valve

– CLOSED

Cap

– Attached to outlet of

valve; chain intact and

connected to valve

Valve

– OPEN

Cap

– Disconnected

or Missing

If valve is OPEN,

CLOSE valve tightly.

If cap is disconnected,

re-connect.

If cap is missing,

contact service provider

for replacement.

Check standpipe

valves

All valves - CLOSED

Any valve OPEN

Ensure all valves are

CLOSED.

5.2. Monthly.

Monthly maintenance consists of standpipe water drainage and quick checks of alarm

response.

Item

Procedure

Normal Status

What To Do If Status Is

Abnormal

Drain water from

standpipe

See

*

below

No water in

standpipe

Draining returns

standpipe to normal

status

Check High Alarm

1. Compressor disconnect

switch ON.

1. Lockable shutoff valve

CLOSED.

2. Operate test / service

device.

Signal horn should

sound when

pressure gauge

indicates 23 ± 1

PSIG

Contact service provider

Check Low Alarm

1. Compressor disconnect

switch OFF.

2. Lockable shutoff valve

CLOSED.

3. Operate test / service

device.

Signal horn should

sound when

pressure gauge

indicates 7 ± 1

PSIG.

Contact service provider

Return To Normal

Status

1. Compressor disconnect

switch ON.

2. Lockable shutoff valve

OPEN.

3. Compressor should run

until standpipe is properly

filled.

1. Compressor off.

2. No abnormal

indications on

control panel.

3. Pressure gauge

indicates between

13 and 18 PSIG.

Contact service provider