GENERAL AIR PRODUCTS, INC.

For Assistance Please Call 1-800 345-8207

Please keep these instructions for future reference.

OILLESSINST

REV 080906

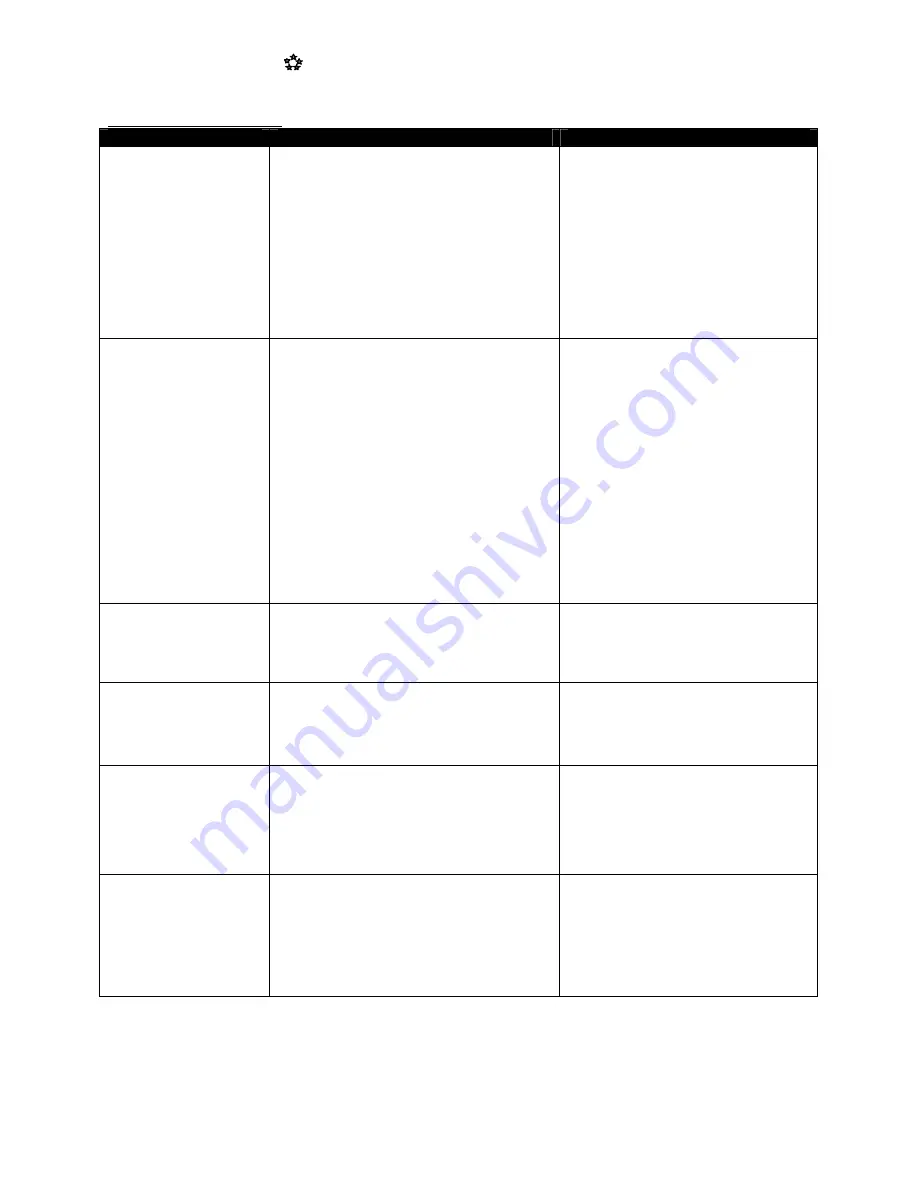

Trouble Shooting Guide

Symptom

Possible Cause(s)

Corrective Action

Motor hums and runs

slowly or not at all

1.

Low voltage or no voltage

2.

Shorted or open motor winding

3.

Defective check valve

4.

Defective pressure switch –

contacts will not close

1.

Check voltage during attempt

to start. Voltage must be

/-10% of nominal

voltage to start motor.

Increase wire size if necessary

to lower voltage drop.

2.

Replace motor

3.

Replace check valve

4.

Repair or replace pressure

switch

Reset mechanism cuts

out repeatedly or fuses

blow repeatedly

1.

Insufficient voltage to motor

2.

Pressure switch set too high

3.

Wrong fuse size

4.

Piping too restrictive

5.

Defective motor

1.

Check voltage during attempt

to start. Voltage must be

/-10% of nominal

voltage to start motor.

Increase wire size if necessary

to lower voltage drop.

2.

Consult factory, adjust or

replace

3.

Be sure fuses and heaters are

rated properly

4.

Add receiver vessel or

increase pipe volume after

compressor.

5.

Replace motor

Unit short cycles

repeatedly

1. Piping too restrictive

2. Leak in line before system check

valve

1.

Add receiver vessel or

increase pipe volume after

compressor.

2.

Repair leaks(s)

Compressor

Overheating

1. Dirty intake filter

2. Wrong motor rotation

3. Air flow to fan on flywheel blocked

1. Clean intake filter

2. Correct rotation

3. Clear air flow to fan or relocate

unit

Excessive noise in

operation

1.

Damaged bearings

2.

Worn piston rings or skirts

3.

Broken valves

4.

Loose blower wheel

5.

Damaged Blower baffle

1. Contact General Air Products,

Inc. Service Department.

1-(800)345-8207

System pressure

builds slowly

1.

Compressor sized incorrectly

2.

Leaks or restrictions in piping

3.

Dirty intake filter

4.

Blown head gasket

1.

Check system size and

compressor sizing

2.

Correct leaks and remove

restrictions

3.

Clean intake filter

4.

Replace head gasket