D770-17-00

3 I56-0986-008R

NOTE: The sensor assembly is not field replaceable. Do not attempt to disas-

semble these parts. If you have any questions, consult System Sensor. System

Sensor recommends careful consideration of the following factors when speci-

fying and installing Alarm and Supervisory Pressure Switches. Always refer to

the Installation and Maintenance Instruction for specific recommendations on

individual devices before installing the unit.

• Electrical ratings stated in literature and on nameplates should not be exceeded.

• Overload on switch can cause failure on the first cycle. Always wire

devices according to national and local electrical codes.

• Install units away from shock and vibration. Proper electrical fittings should

be used to prevent moisture from entering the enclosure via the conduit.

• Test all devices for proper operation after initial installation. Perform pre-

ventive maintenance and periodic testing as required by the applicable

NFPA standards but not less than bimonthly.

• Install a back-up control for all critical applications where control failure

could endanger life or property. A backup control to serve as a high or

low limit control is especially recommended for applications where a

runaway condition could result.

• Do not mount unit where ambient temperatures will exceed published limits.

• Avoid impact or mechanical loading.

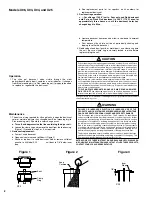

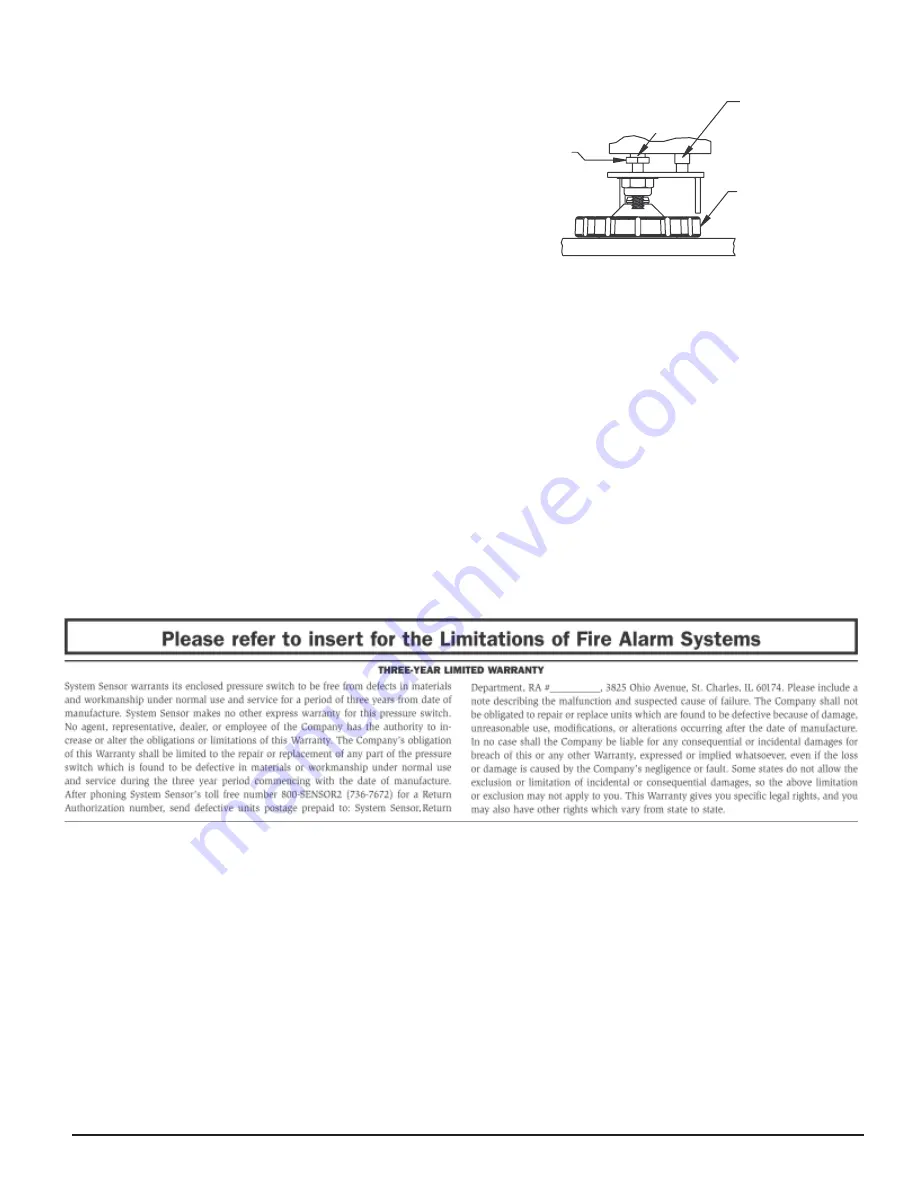

Low Pressure

Adjusting

Screw

1/4" Hex Head

(Not Present in

Single Switch

Models)

Each 1/2 turn of Low Pressure adjsuting screw adjusts

pressure approximately 5 psi. Turn counter clockwise to increase

pressure. Turn clockwise to decrease pressure. Each 1/2 turn

of High Pressure adjusting wheel adjusts pressure 11 psi on the

EPS40-2 and 40 psi on the EPS120-2.

NOTE:

Main Adjusting Wheel

(Turn Counterclockwise

to Increase Pressure)

Switch 2

(Low Switch

EPS40-2 and

EPS120-2)

Switch 1

(High Switch

EPS40-2 and

EPS120-2; Low

Switch EPS40-1)

FIGURE 5. ADJUSTMENTS (DUAL-SWITCH MODEL SHOWN):

W0144-02