CIB UNIGAS - M039177CA

5

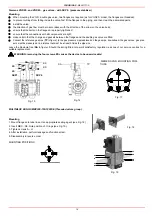

GENERAL FEATURES

This series of industrial burners is designed for all those applications that require big-sized air fans or air-flue heat exchangers to be

installed in sound-proof areas to reduce noise. They can be provided with built-in or separately-mounted control panel (console or wall-

mounted).

Fig. 1

1

Adjusting cam

2

Servocontrol

3

Bellows

4

Burner flange

5

Junction box

6

Combustion head adjusting screw

7

Gas filter

8

Gas proving system

9

Gas valves group

10 Cover

11 Combustion head-blast tube group

The gas coming from the supply line, passes through the valves group provided with filter and stabiliser. This one forces the pressure in

the utilisation limits. The electric servocontrol (2), that moves proportionally the air damper and the gas butterfly valve, uses an adju-

sting cam (1) with variable shape. This one allows the optimisation of the gas flue values, as to get an efficient combustion. The combu-

stion head positioning determines the burner’s output. The combustion head (11) determines the energetic quality and the geometry of

the flame. Fuel and comburent are routed into separated ways as far as the zone of flame generation (combustion chamber). The air

(comburent) and fuel (gas) are forced into the combustion chamber.

PART I: INSTALLATION MANUAL

9

12

8

5

7

6

4

3

2

1

11

10

Summary of Contents for TP512A

Page 43: ...CIB UNIGAS M039177CA 43 Wiring diagram 21 001 2 Progressive burners ...

Page 44: ...CIB UNIGAS M039177CA 44 Wiring diagram 21 001 2 Fully modulating burners ...

Page 46: ...CIB UNIGAS M039177CA 46 ...

Page 47: ...CIB UNIGAS M039177CA 47 ...

Page 48: ...CIB UNIGAS M039177CA 48 ...

Page 49: ...CIB UNIGAS M039177CA 49 WIRING DIAGRAM Cod 09 315 1 Burners type TP525A Mod M MD x xx x 1 xx ...

Page 50: ...CIB UNIGAS M039177CA 50 ...

Page 51: ...CIB UNIGAS M039177CA 51 ...

Page 52: ...CIB UNIGAS M039177CA 52 ...

Page 55: ...CIB UNIGAS M039177CA 55 ...

Page 56: ......