CIB UNIGAS - M039177CA

35

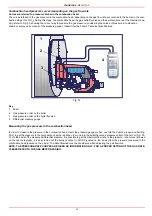

OPERATION

z

Turn to the “ON” position the main switch A, on the burner’s control panel (see Fig. 34).

z

Check the flame control device is not locked (light B, on) and eventually release it by means of the pushbutton C (reset - for more

information about the device, please refer to the manual’s Appendix).

z

Check the series of thermostats or pressure switches gives the burner the start signal for operating.

z

Check that the gas pressure in the gas network is sufficient (if the pressure is normal, the lamp E lights).

z

The check cycle of the gas proving system starts; the end of this check is signalled by the lamp on the device (see pag. 25). To

unlock the system, press the reset pushbutton on the gas proving system.

z

The fan motor starts, the servocontrol drives the air damper to the maximum opening position (light G on); the pre-purge time coun-

tdown starts now (30 seconds).

z

At the end of the pre-purgue time, the air damper moves to the ignition position (about 5°), the ignition transformer is energized

(light I on), the solenoid gas valves EV1 and EV2 are energized (lights L and M).

z

The flame must appear within 3 seconds after the gas valves opening, the transformer is de-energized and the light I is turned off.

The burner is now operating and at the same time the servocontrol moves to the hi-flame position (90° - see pag. 26).

z

24 seconds after the gas valves opening, the burner starts the automatic operation: it works in high or low-flame operation (for pro-

gressive PR- burners) or in the phase requested by the burner modulator (Fully modulating - MD buners) according to the require-

ments of the plant.

Fig. 34: Burner’s electrical board front panel

ATTENTION: before starting the burner up, be sure that the manual shutoff valves are open and check that the pres-

sure value upstream the gas train matches the value on paragraph “Technical specifications”). Check that the

mains switch is closed.

Key

A Main switch

B

Lock-out light

C

Reset pushbutton for control box

D

Reset pushbutton for gas proving system

(only for burners provided with Siemens

LDU11)

E

Gas pressure switch consent

F

Lock-out light for gas proving system

G

Hi-flame operation light

H

Lo-flame operation light

I

Ignition transformer operation light

L

EV2 opening light

M

EV1 opening light

N

Fan motor overload tripped light

O

Burner in stand-by light

P

Burner Modulator (only on fully modula-

ting burners)

M

F

D

P

A

C

E

L

N

G

H

B

I

O

Summary of Contents for TP512A

Page 43: ...CIB UNIGAS M039177CA 43 Wiring diagram 21 001 2 Progressive burners ...

Page 44: ...CIB UNIGAS M039177CA 44 Wiring diagram 21 001 2 Fully modulating burners ...

Page 46: ...CIB UNIGAS M039177CA 46 ...

Page 47: ...CIB UNIGAS M039177CA 47 ...

Page 48: ...CIB UNIGAS M039177CA 48 ...

Page 49: ...CIB UNIGAS M039177CA 49 WIRING DIAGRAM Cod 09 315 1 Burners type TP525A Mod M MD x xx x 1 xx ...

Page 50: ...CIB UNIGAS M039177CA 50 ...

Page 51: ...CIB UNIGAS M039177CA 51 ...

Page 52: ...CIB UNIGAS M039177CA 52 ...

Page 55: ...CIB UNIGAS M039177CA 55 ...

Page 56: ......