CIB UNIGAS - M039177CA

25

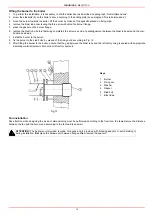

ADJUSTING AIR AND GAS FLOW RATES

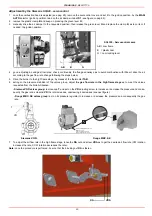

Gas Filter (Fig. 31 - 1)

The gas filters remove the dust particles that are present in the gas, and prevent the elements at risk (e.g.: burners, counters and regu-

lators) from becoming rapidly blocked. The filter is normally installed upstream from all the control and on-off devices.

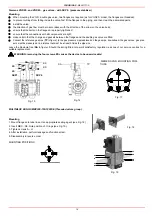

Servocontrol (Fig. 31- 5)

Two servocontrol models can be provided:

z

Berger STM30.. (see pag. 28) or

z

Siemens SQL33.. (see pag. 30).

Fig. 31

Keys

1

Gas filter

2

Gas proving system

3

Gas valves

4

Adjusting cam

5

Servocontrol

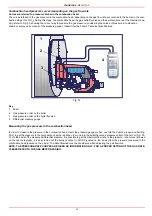

VPS504 Gas proving system (Fig. 31 - 3)

The VPS504 check the operation of the seal of the gas shut

off valves. This check is carried out as soon as the boiler

thermostat TAB gives a start signal to the burner, creating,

by means of the diaphragm pump inside it, a pressure in the

test space of 20 mbar higher than the supply pressure.

When wishing to monitor the test, install a pressure gauge

into the pressure supply point PA.

If the test cycle is satisfactory, after a few seconds the con-

sent light LC (yellow) comes on. Otherwise, the lockout light

LB (red) comes on.

To restart, it is necessary to reset the appliance by pressing

the pushbutton LB.

Fig. 32

3

4

5

1

2

LC

LB

PA

Summary of Contents for TP512A

Page 43: ...CIB UNIGAS M039177CA 43 Wiring diagram 21 001 2 Progressive burners ...

Page 44: ...CIB UNIGAS M039177CA 44 Wiring diagram 21 001 2 Fully modulating burners ...

Page 46: ...CIB UNIGAS M039177CA 46 ...

Page 47: ...CIB UNIGAS M039177CA 47 ...

Page 48: ...CIB UNIGAS M039177CA 48 ...

Page 49: ...CIB UNIGAS M039177CA 49 WIRING DIAGRAM Cod 09 315 1 Burners type TP525A Mod M MD x xx x 1 xx ...

Page 50: ...CIB UNIGAS M039177CA 50 ...

Page 51: ...CIB UNIGAS M039177CA 51 ...

Page 52: ...CIB UNIGAS M039177CA 52 ...

Page 55: ...CIB UNIGAS M039177CA 55 ...

Page 56: ......