5

Maintenance

Removing Air from the Piston Chambers

106

Accela 600 and 1250 Pump Hardware Manual

Thermo Scientific

Removing Air from the Piston Chambers

Air trapped in the piston chambers causes an excessive variation in the backpressure.

To purge air out of the piston chambers

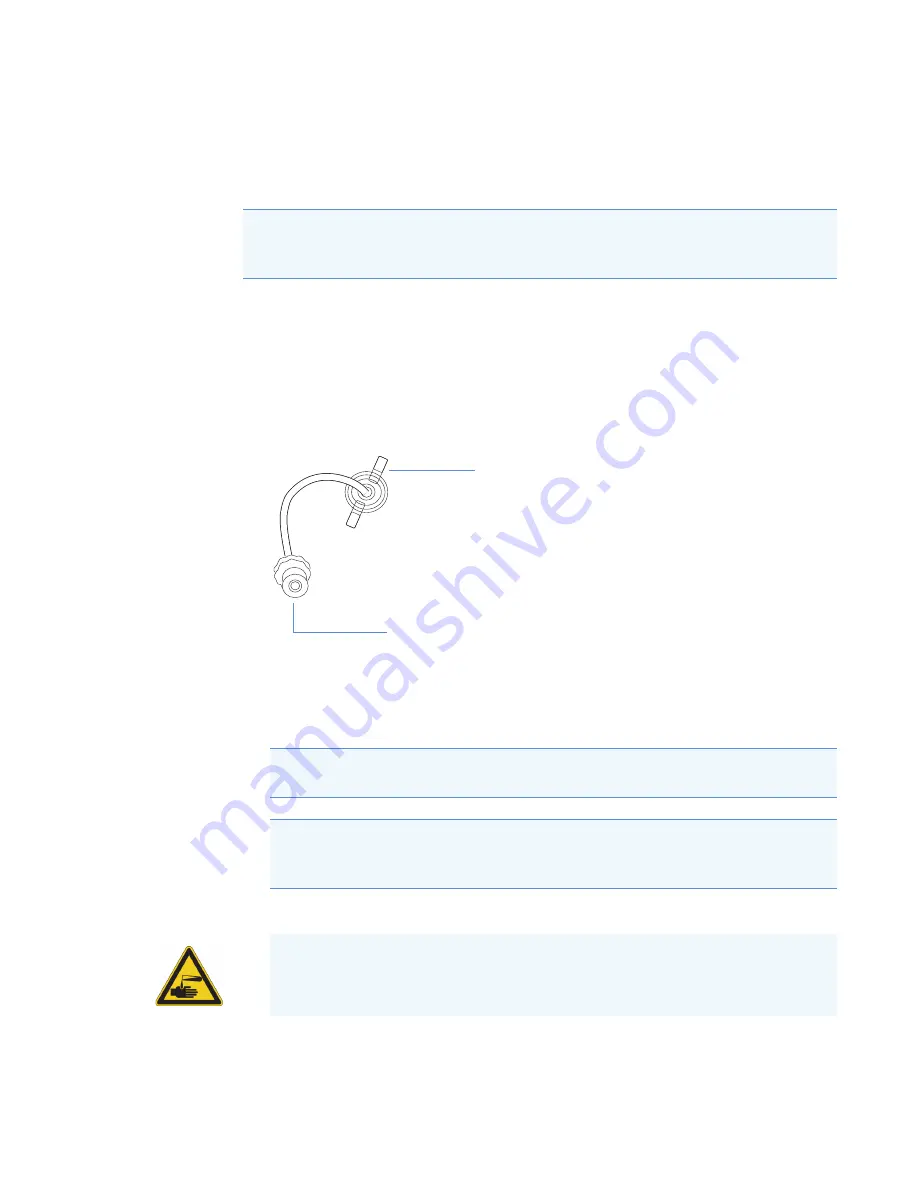

1. Open the purge valve by turning its wing nut counterclockwise (see

2. To collect the solvent being pumped through the LDA, insert the tip of a

10 mL disposable syringe into the tubing attached to the purge valve.

Figure 106.

Purge valve with tubing attached

3. Pump 100% methanol or 100% acetonitrile through the LDA at a flow rate of

200 μL/min for 10 to 15 minutes.

4. Close the purge valve, remove the syringe, and return to the initial conditions.

5. Check the pressure variation to determine if removing the trapped air stabilized the

system pressure.

Note

All low-pressure mixing HPLC pumps require eluents that have been properly

degassed. The pump has a built-in vacuum degasser. Plumbing the pump to bypass this

degasser introduces a potentially unacceptable level of air into the piston chambers.

Tip

Purging the pump at a low flow rate with 100% organic solvent works much

better than purging the pump at a high flow rate with (partly) aqueous eluents.

Note

Due to seal friction, the system backpressure does not drop to zero when you

pump solvent through the open purge valve. Depending on the flow rate and solvent

composition, typical backpressure values range from 5 to 15 bar.

Tubing

(with fitting

for syringe)

Purge valve wing nut

CAUTION

Wear safety gloves when handling solvents.