(© Oct, 2007)

Compact CW Series Installation, Operation & Maintenance Manual

Air Technology Systems, Inc.

2-2

walls can be a polyethylene film. Concrete walls and

floors should be painted with a rubber or plastic based

paint. Doors and windows should be properly sealed

and a door sweep used to minimize leakage. Outside

or fresh air should be kept to a minimum (as it adds to

the cooling, heating, dehumidification and humidifying

loads), while still maintaining the requirement of the

Indoor Air Quality (IAQ) standard. Lack of attention to

these factors can cause erratic operation, unstable

room control and excessive maintenance costs.

2.3

Rigging

Compact CW systems are designed to be kept in the

vertical position. Move the unit with a suitable device

such as a forklift, roller bar, pallet jack or dollies. For

reference, a weight table is provided on the installation

drawing. Units are shipped on a skid to facilitate

moving prior to installation. Units should always be

stored indoors in a dry location prior to installation.

CAUTION

When moving the unit, it must be kept level and

in the vertical position to prevent damage.

2.4

Mounting/Placement

Compact CW systems that are not ducted are de-

signed to be located in the conditioned space. Ducted

units may be located inside or outside the conditioned

space, but are designed to supply air to only one

room. The

Compact CW systems are front accessible,

which allows the units to be placed in a corner or

between cabinetry. It is recommended that the unit is

positioned to obtain optimum air circulation.

NOTE

Placement of the floor or ceiling registers is im-

portant. If they are too close to the unit, the sup-

ply air will be re-circulated back to the unit be-

fore it has circulated throughout the space.

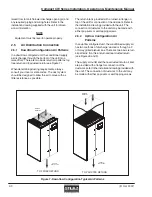

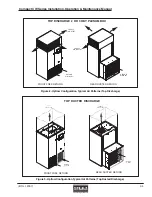

See Figures 5 and 6. The unit is designed to be

located directly on top of the floor (typically upflow) or

on a raised floor (typically downflow).

CAUTION

Ensure the mounting surface is capable of sup-

porting the weight of the equipment. Before mount-

ing the unit, refer to the weight table provided on

the installation drawing. On some raised floor in-

stallations, a floor stand is required, depending

on the load capacity of the existing raised floor.

SERVICE

SWITCH

HINGED

DOOR

OPTIONAL

FLOOR STAND

Figure 6- Typical Installation Downflow

Figure 5- Typical Installation Upflow

PLENUM BOX

ASSEMBLY

(OPTIONAL)

HINGED

DOOR

SERVICE

SWITCH

2.4.1

Precision A/C Unit

The

Compact CW system uses a frame and panel

construction for unit rigidity and full service accessibil-

ity without moving the unit. If a floor stand is used,

refer to the installation drawing provided and cut out

the raised floor to match the unit’s overall base

dimension. If a floor stand is not used, cut out the