(© Oct, 2007)

Air Technology Systems, Inc.

Compact CW Series Installation, Operation & Maintenance Manual

2.6 Optional Equipment (Field Installed)

NOTE

Do not mount any optional equipment on the

unit access doors.

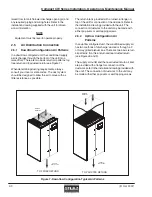

2.6.1 Floor Stand

Install the floor stand directly on the sub-floor, ensuring

the side with the "FRONT" label is facing the same

direction as the front of the precision A/C unit (see

Figure 10). Refer to the floor stand assembly drawing for

the dimensions required to cut the raised floor. The

optional floor stand is designed with adjustable feet on

all the legs, allowing for leveling and and overall height

adjustment. Refer to the floor stand assembly drawing

for minimum and maximum height adjustability of your

floor stand. To adjust the height, first loosen the middle

nuts on each leg. Next, turn the top hex nuts to raise or

lower the floor stand. Once the floor stand is level and

even with the raised floor, lock all feet in place by

tightening the middle hex nuts against the top hex nuts.

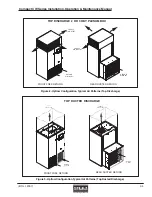

2.6.2 Plenum Box Assembly

The plenum box assembly is shipped loose. To install

the 2 or 3-way optional plenum box, place the assembly

on top of the unit (see Figure 5). Remove the front grille

for access to attach the plenum with the supplied self-

tapping screws. Holes are pre-drilled in the unit and the

plenum box assembly.

2.6.3 Remote Display

As an option, a factory supplied control panel may be

remote mounted. For mounting and wiring instructions,

2-5

refer to the system drawings and the supplemental

manual sent in the data package with your unit.

2.6.4 Condensate Pump

An optional, factory installed condensate pump may be

provided for automatically eliminating condensate and

humidifier flush water from the drain pan. The conden-

sate pump is typically installed by the factory inside

the A/C unit. If an optional, field installed condensate

pump is selected, it should be located as near as

possible to the air conditioning system. The pump

should be positioned so the inlet hole in the pump is

below the drain pan inside the A/C unit. The pump

includes a mounting bracket with two holes to secure

it in place. Ensure that the pump is level for proper

operation.

2.6.5 Remote Temperature/Humidity Sensor

The remote (T/H) sensor must be located so that it will

properly sense the temperature/humidity conditions to

be controlled. Depending on the type of control desired

(see Section 2.6.5.1), the sensor(s) may be factory

mounted and/or shipped loose for field installation.

The T/H sensor should not be mounted near a door-

way, near or above any heat producing equipment or in

an area where it would be exposed to direct sunlight.

Follow the steps below to mount the sensor.

Temperature/Humidity Sensor

1.

Using a flat head screwdriver, remove the cover

plate from the base.

2.

Place the base temporarily over the wire hole

opening in the wall. Level the base and mark the

mounting hole locations through the two slots.

3.

Drill the mounting holes and insert the wall

anchors provided.

4.

Run the wires coming out of the wall through the

hole in the base, then secure the base with the

screws provided.

5.

Make the wiring connections. For wiring details,

see Section 2.8 (Utility Connections) and refer to

the wiring diagram supplied with your unit.

6.

Replace the unit cover plate on the base.

COVER

SCREW

Figure 10- Optional Floor Stand Installation

THREADED ROD

MIDDLE HEX NUT

TOP HEX NUT

ISOLATION PAD

FLOOR STAND LEG

"FRONT" LABEL